Bearingless synchronous reluctance motor decoupling control system and construction method thereof

A synchronous reluctance motor and decoupling control technology, applied in control systems, vector control systems, motor generator control, etc., can solve problems such as poor motor transient response, motor flux linkage orientation, and increased implementation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the content of the present invention more comprehensible, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

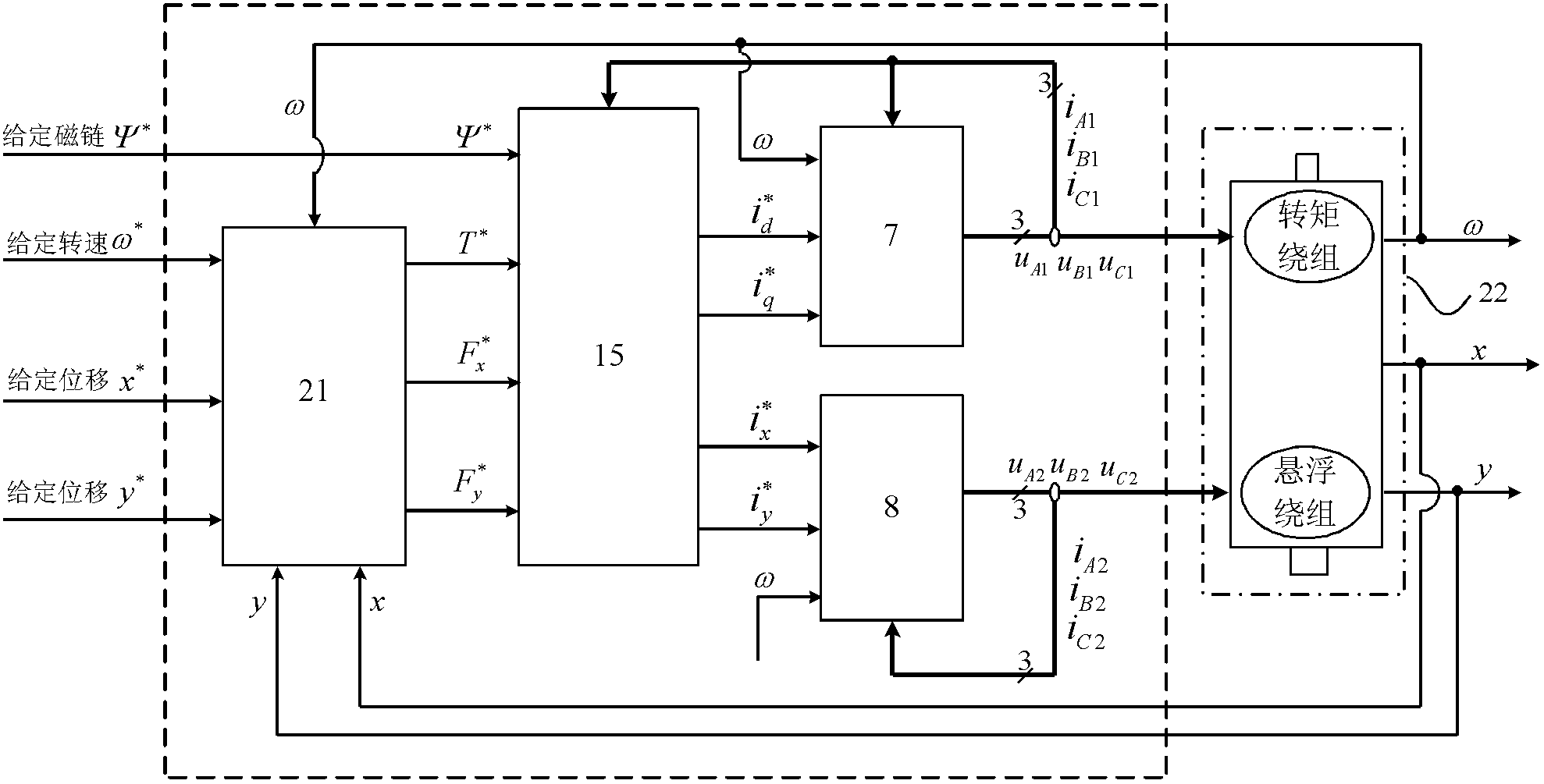

[0064] combine figure 1 , the bearingless synchronous reluctance motor decoupling control system of the present invention includes an expanded closed-loop regulator 21, a field-oriented decoupling model 15 and two expanded SVPWM inverters 7, 8, wherein:

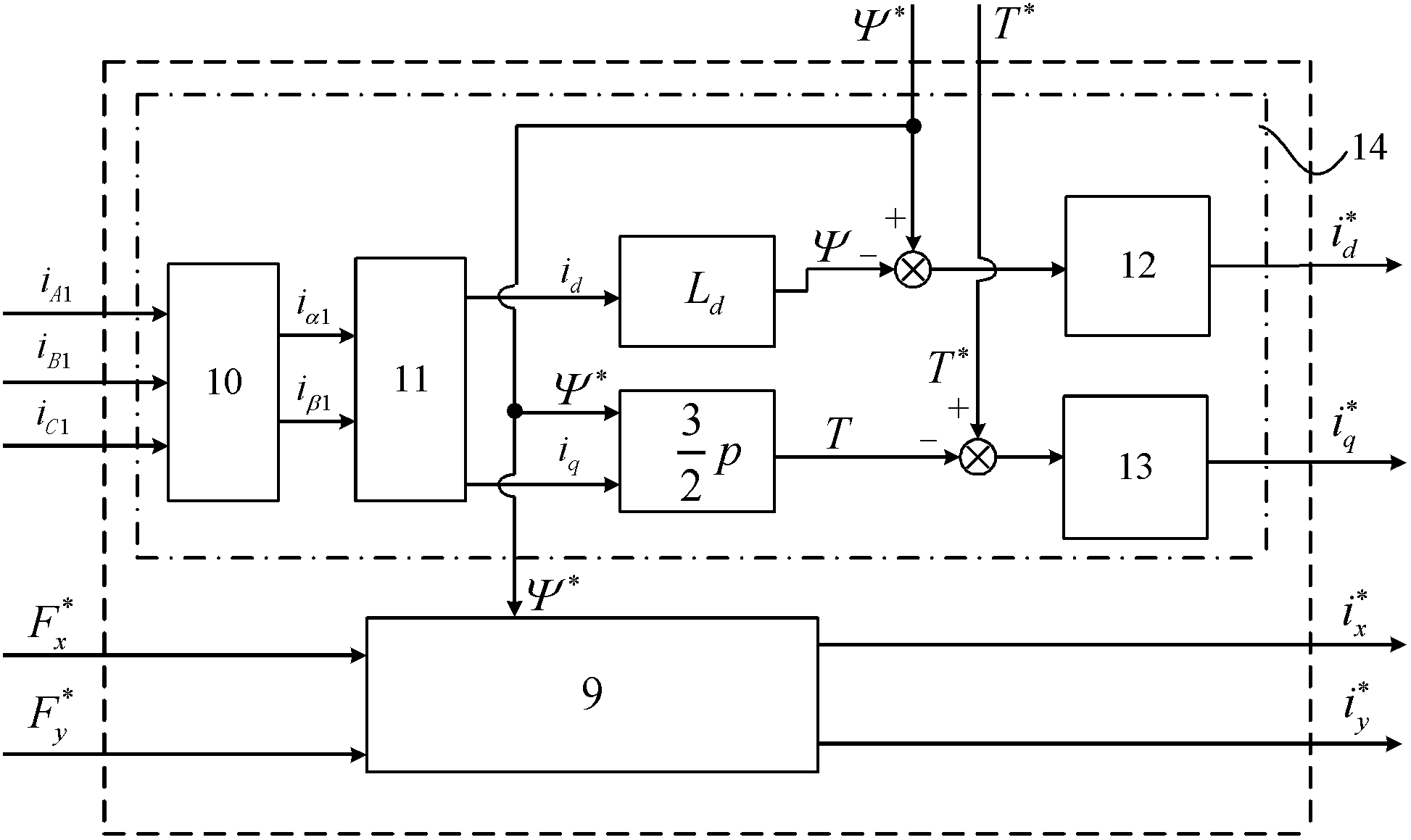

[0065] Such as Figure 4 As shown, the extended closed-loop regulator 21 is composed of a closed-loop regulator 19 and a unilateral magnetic pull compensation model 20; the closed-loop regulator 19 is based on the given displacement, detected displacement, given rotational speed and detected rotational speed in the two-axis direction of the rotor as Input signal, output torque given value and two hybrid levitation force components; unilateral magnetic pull force compensation model 20 takes the detected displacement on the two-axis di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com