Decoupling method and control device for suspension force feed-forward compensation of bearingless permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and feedforward compensation, which is applied in the direction of motor generator control, electromechanical transmission control, electronic commutation motor control, etc. It can solve the problem of poor robustness, slow dynamic response, Problems such as increased difficulty in project realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the content of the present invention more obvious and understandable, further description will be given below in conjunction with the accompanying drawings and specific embodiments.

[0054] Combine Figure 4 , A bearingless permanent magnet synchronous motor suspension force feedforward compensation decoupling method of the present invention includes the following steps:

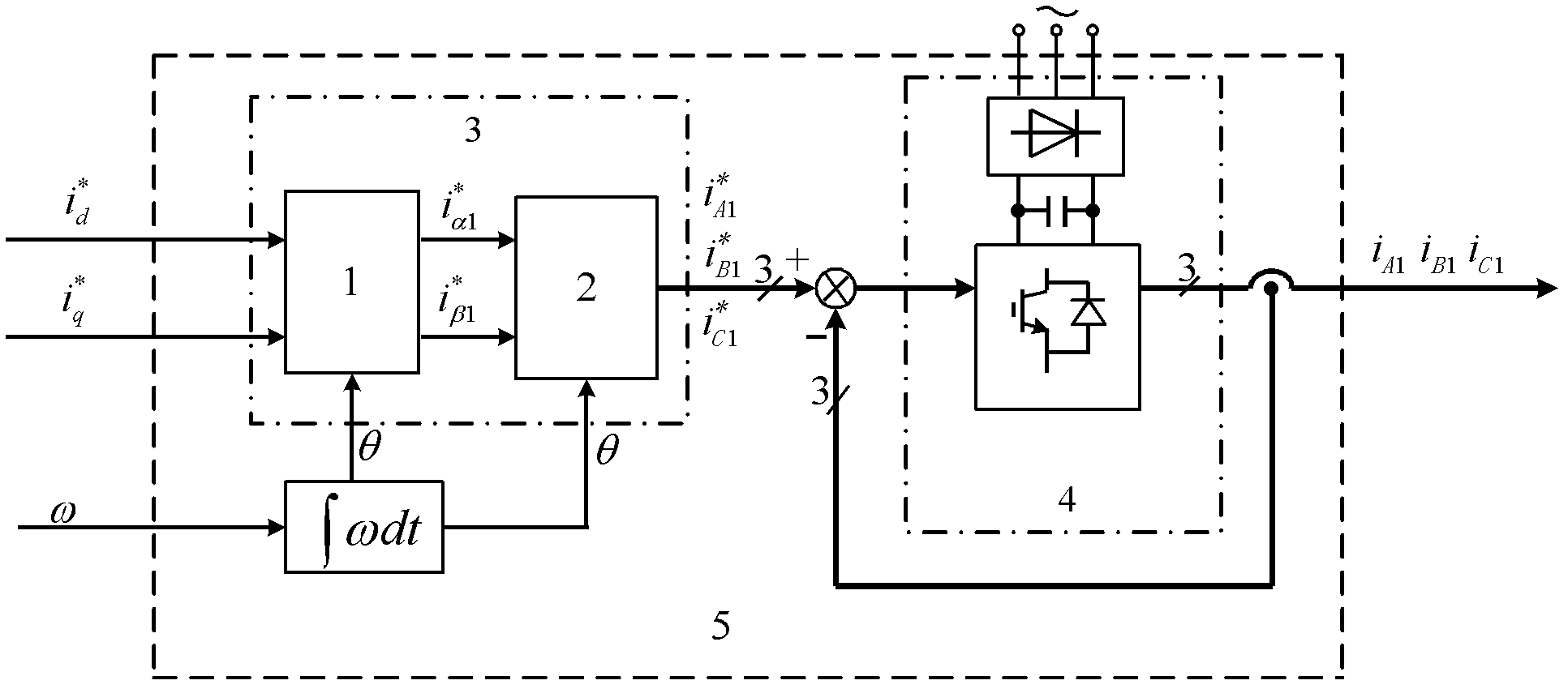

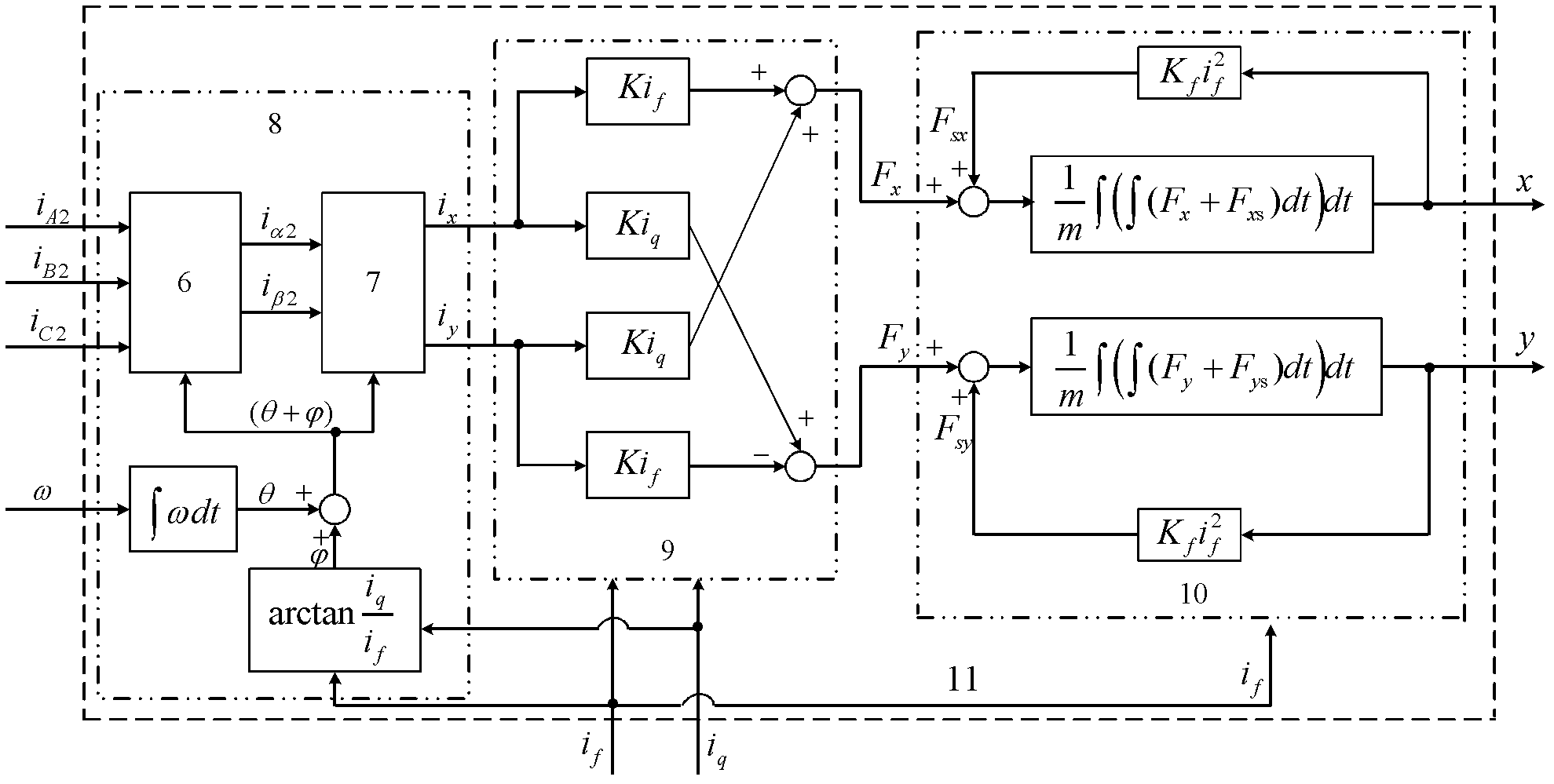

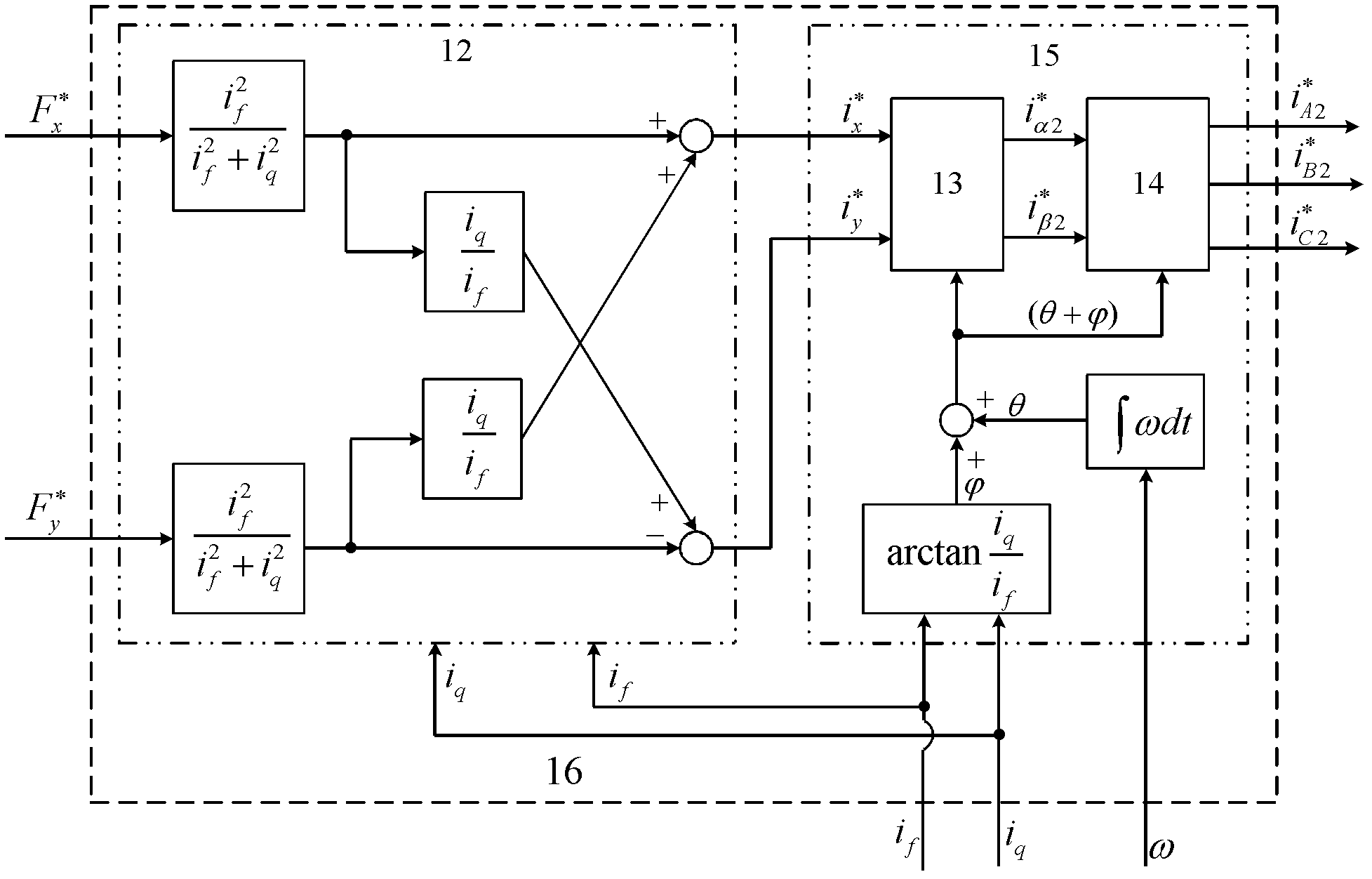

[0055] 1) Construct an extended current hysteresis PWM inverter 5, which uses the two components of the stator current of the controlled motor torque winding with The speed detection value ω is used as the input signal, and the three-phase actual current i is output A1 , I B1 , I C1 The three-phase torque winding to the controlled motor is used to adjust the speed. Such as figure 1 As shown, the extended current hysteresis PWM inverter includes coordinate transformation part 3, integral operation and current hysteresis PWM inverter 4; two components of the stator current of the controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com