Rice cooking production line

A production line and rice technology, applied in application, food preparation, food science and other directions, can solve the problems of no production line configuration function, reduced labor productivity, low processing efficiency, etc., to facilitate continuous production, improve labor productivity, and heat up. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

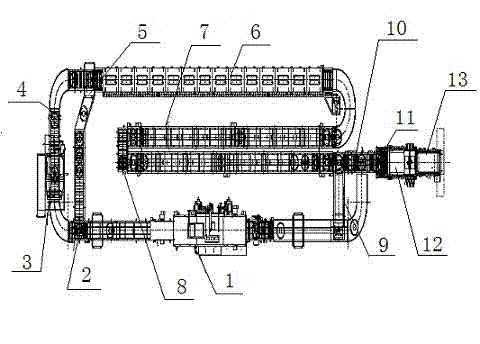

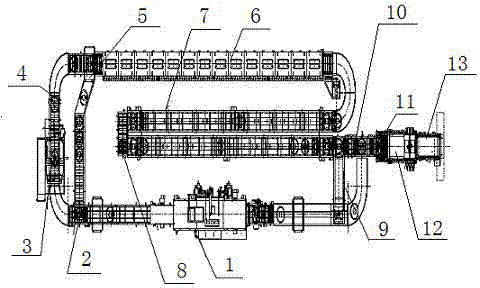

[0010] Such as figure 1 As shown, the rice cooking production line includes an online sterilization cleaning machine 1, a cover removal machine 2, a water rice distribution machine 3, an ingredient feeding mixer 4, a cover machine 5, an online heating machine 6, and an online heat preservation machine 7, which are connected in sequence , transplanting machine 8, separator 9, seasoning adding mixer 10, take-out machine 11, dispersing machine 12 and conveyor 13, on-line sterilizing cleaning machine 1 uses ozone and ultraviolet rays to sterilize, so that the pot and pot cover can meet the hygienic use standard, The cover removing machine 2 separates the pot cover from the line body, and the rice is injected into the pot simultaneously with the water and rice proportioning machine 3 and water, and the ingredients are put in and stirred by the ingredient feeding mixer 4 so that it is fully mixed with the rice. Put the lid on the pot to close the pot body, heat the rice to a fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com