Chicken meal and production method thereof

A production method and technology for chicken powder, which are applied in the fields of application, food preparation, food science, etc., can solve the problems of unsatisfactory aroma and nutritional value of taste, and achieve the effects of pure and rich aroma, simple and easy production process and excellent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

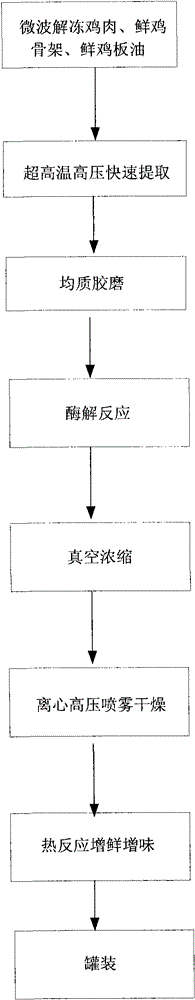

Image

Examples

Embodiment 1

[0021] A kind of chicken powder, it is prepared by following production method:

[0022] Step A, microwave thawing: take by weight percentage and be 50% chicken, 30% fresh chicken skeleton, 10% fresh chicken suet and 10% edible salt, chicken, fresh chicken skeleton and fresh chicken suet are carried out microwave heating When the temperature is raised, the temperature rises from below the deep freezing temperature of -19~-22°C to about 0~-4°C close to the freezing point. Under the action of high-frequency electromagnetic, microwave heating makes the movement of the material molecules rub against each other, thereby generating heat and making fresh Chicken, fresh chicken skeleton and fresh chicken suet are fully sterilized and thawed.

[0023] Step B, ultra-high temperature and high pressure rapid extraction: Put the chicken and fresh chicken skeleton treated in step A into the extraction tank and heat it quickly until the central temperature in the tank reaches 140°C, keep it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com