Magnetic compression anastomosis ball

A magnetic and magnetic technology, applied in the field of magnetic compression anastomotic balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

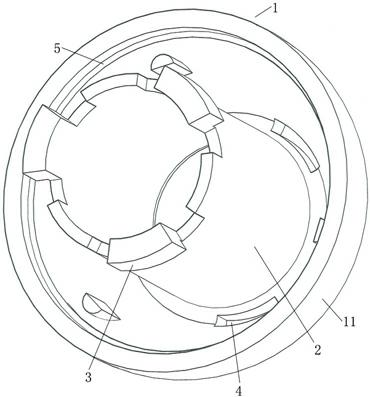

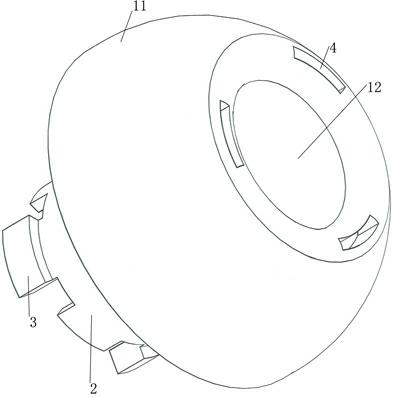

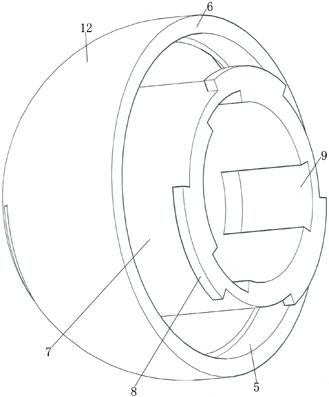

[0048] The magnetic pressure anastomotic ball as a whole includes component I and component II, Figure 1~2 shows the overall structure of assembly I, Figure 3-7 The overall structure of component II is shown, and the anastomotic ball will be introduced in detail below.

[0049] It can be seen from the figure that the assembly I includes a rotary housing I11 and a cylinder I2. In order to make the anastomotic ball less likely to damage the gastrointestinal mucosa, less likely to damage the intestinal tract when moving in the intestine after falling off, and to facilitate excretion from the body, the rotary housing I is required to have a smooth surface. The prime line of the revolving shell I is a smooth curve, and the two ends of the curve are at a certain distance from the axis. In this way, the revolving shell I has two open ends, which are respectively a large opening end and a small opening end. The distance from the point on the prime line near the large mouth end to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com