Automatic light-transforming blinkers for welding operation

An automatic dimming and operation technology, applied in the field of goggles, can solve the problems of high cost, inability to completely free hands, affect welding quality and work efficiency, etc., achieve light weight, improve welding quality and work efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

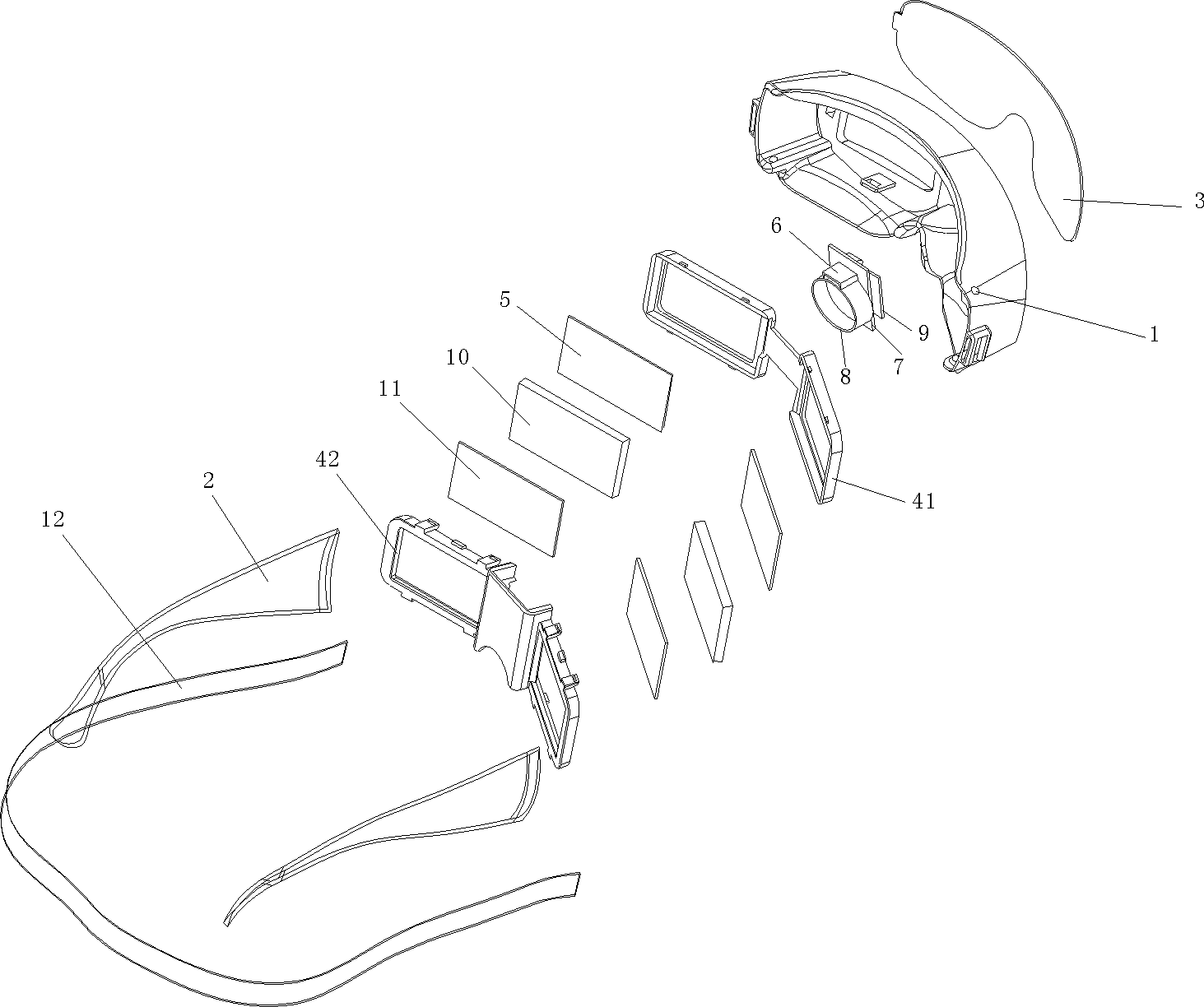

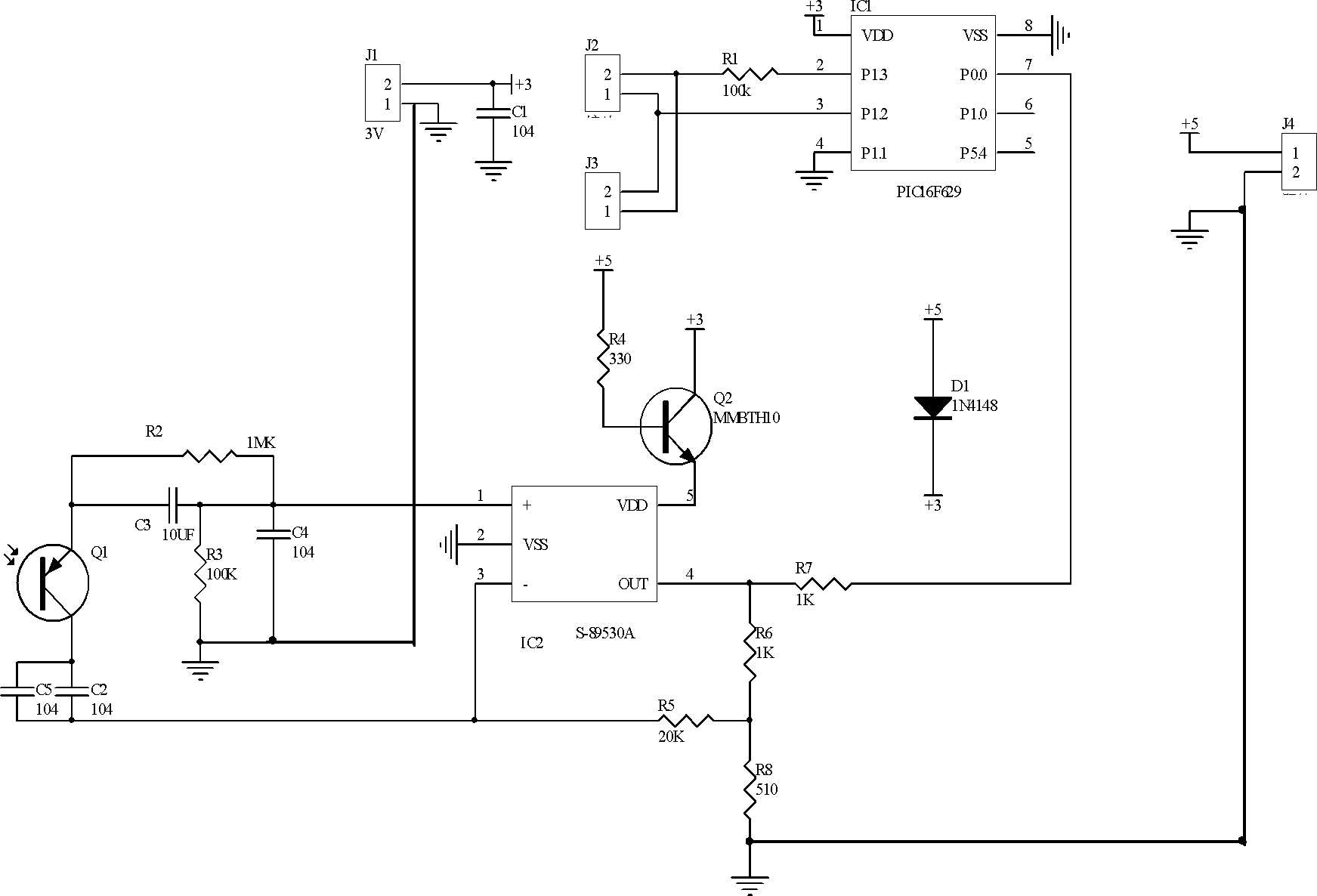

[0017] see figure 1 , The embodiment of the present invention is provided with a frame 1, a mirror foot 2, a lens 3 and an automatic dimming device. The automatic dimming device is provided with a frame cover (composed of a front cover 41 and a rear cover 42), an optical filter 5, a liquid crystal light valve plate 10 (LCD liquid crystal light valve plate), a photoelectric sensor 6, a control circuit 7, and a button battery 8 And the solar cell 9; the picture frame 1 is provided with a cavity, and the frame cover is embedded in the cavity of the picture frame. Both the front cover 41 and the rear cover 42 of the frame cover are binocular frame-type frame covers, and the front cover 41 and the rear cover 42 are snap-fit connected. There are two optical filters 5, two liquid crystal light valves 10, two optical filters 5 are installed on the front cover 41, two liquid crystal light valves 10 are installed on the rear cover 42, and the light filter The sheet 5 is located behi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com