Production process of unstable chemical injection

A technology of stabilizers and substances, applied in the production process of unstable compound injections, which can solve the problems of adenosine triphosphate decomposition, turbidity, product precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

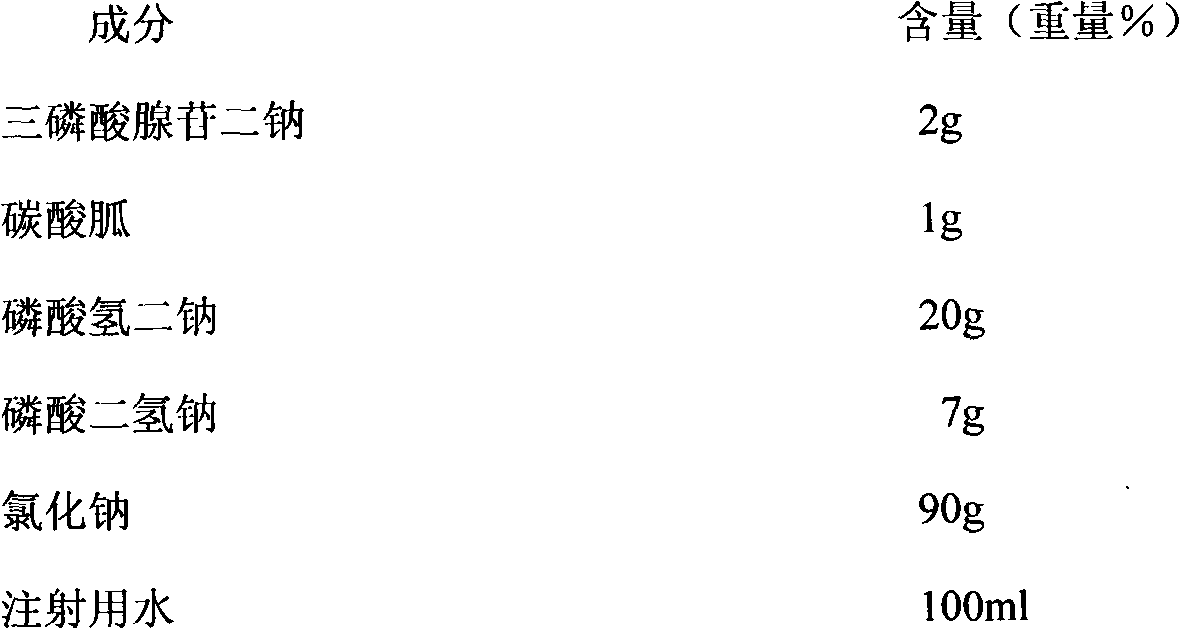

[0017] Preparation Example 1: Injection stock solution containing adenosine disodium triphosphate and sodium chloride component:

[0018]

[0019]

[0020] Weigh a certain amount of guanidine carbonate and dissolve it in an appropriate amount of water for injection, add disodium hydrogen phosphate, sodium dihydrogen phosphate, sodium chloride, and disodium adenosine triphosphate in sequence to dissolve it, and add 0.05% (mg / ml) weight by volume Activated carbon is used for needles, after fully stirring, coarse filter and decarbonize, add water to 100ml. Sterilize with live steam at 120°C for 30 minutes. Cool, dilute with sterile water for injection to 1000ml, filter with 0.22μm filter membrane, press the filtrate under 300MPa pressure, pressurize for 20min, canned, cover the sterilized aluminum cap; package, get adenosine disodium triphosphate sodium chloride injection Liquid finished product.

preparation example 2

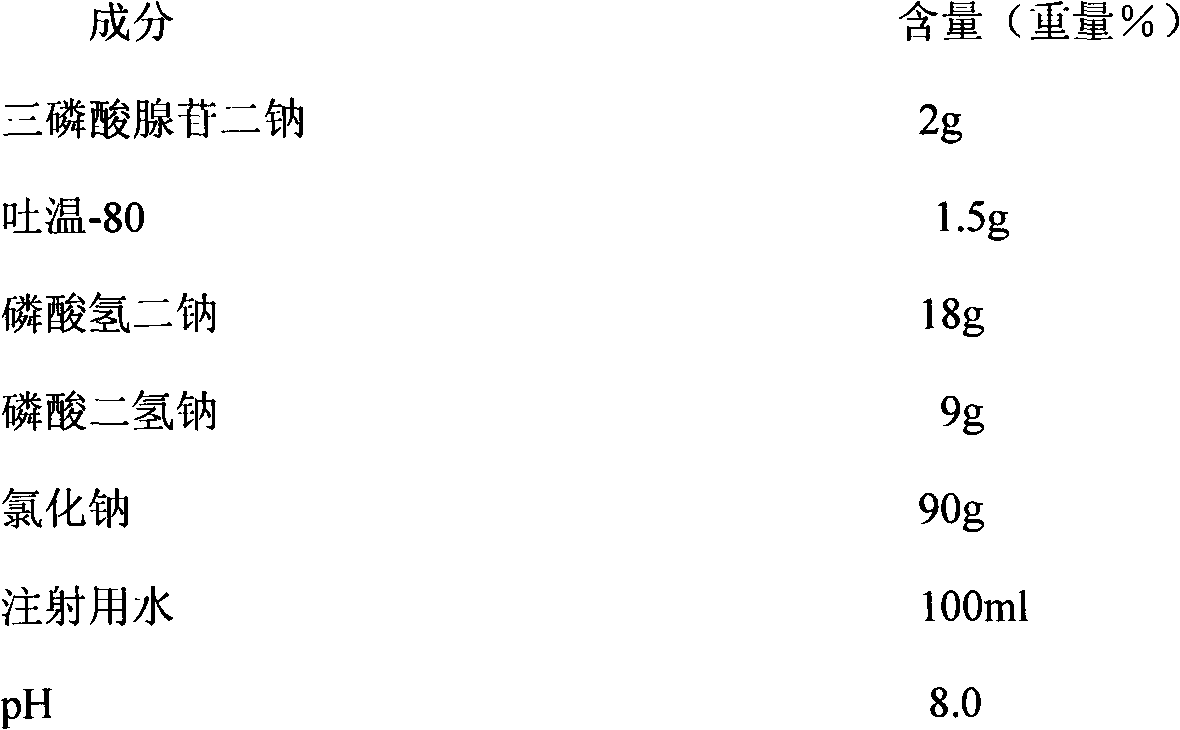

[0021] Preparation Example 2: Injection stock solution containing adenosine disodium triphosphate and sodium chloride component:

[0022]

[0023] Weigh a certain amount of Tween-80 and dissolve it in an appropriate amount of water for injection, add disodium hydrogen phosphate, sodium dihydrogen phosphate, sodium chloride, and adenosine disodium triphosphate in sequence to dissolve it and add 0.05% by volume (mg / ml) The weight of activated carbon for needles, after fully stirring, coarse filtration and decarbonization, add water to 100ml. Sterilize with live steam at 120°C for 30 minutes. Cool, dilute with sterile water for injection to 1000ml, filter with 0.22μm filter membrane, press the filtrate under 300MPa pressure, pressurize for 20min, canned, cover the sterilized aluminum cap; package, get adenosine disodium triphosphate sodium chloride injection Liquid finished product.

preparation example 3

[0024] Preparation Example 3: Replace the stabilizer in Example 1 or 2 with the same content of propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com