Open boiling liquid nitrogen system with liquid nitrogen recovery device

A recovery device and liquid nitrogen technology, applied in the field of open boiling liquid nitrogen system, to achieve the effect of saving test costs, small investment and short cost recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

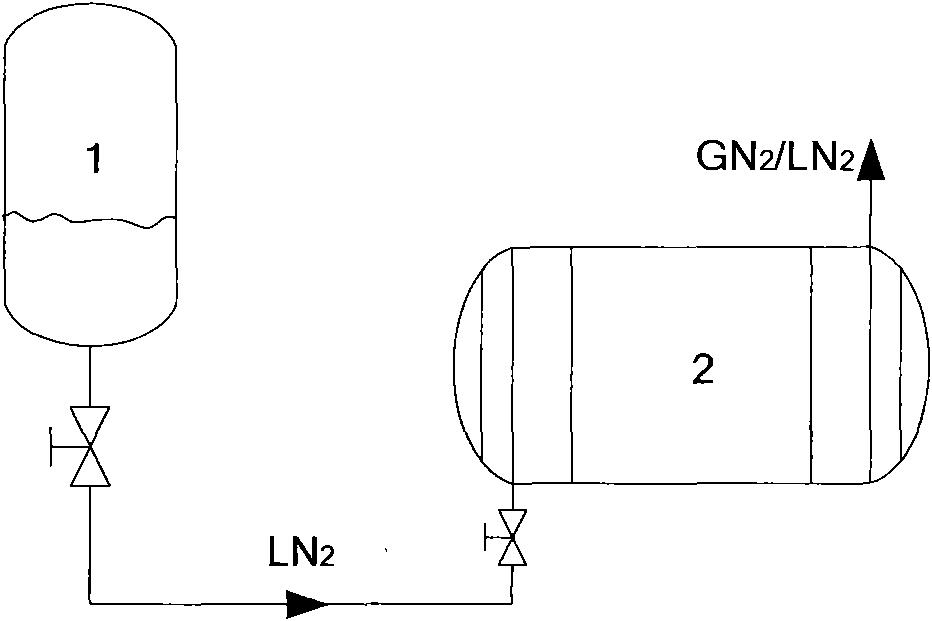

[0010] figure 1 It is a schematic structural diagram of a traditional open boiling liquid nitrogen system. The device includes: a liquid nitrogen storage tank 1 sends liquid nitrogen to a thermal vacuum environment simulation device 2 through a low temperature system pipeline, and then empties it through a vent pipeline. Its working principle is: the liquid nitrogen in the system enters the heat sink of the thermal vacuum environment simulation equipment 2 from the liquid storage tank 1 through the low-temperature system pipeline, and then is directly emptied through the vent pipeline, and the liquid nitrogen in the system is gasified in a large amount during the flow process , take away the heat radiated from the test piece in the system and the simulator to the heat sink through the phase change heat.

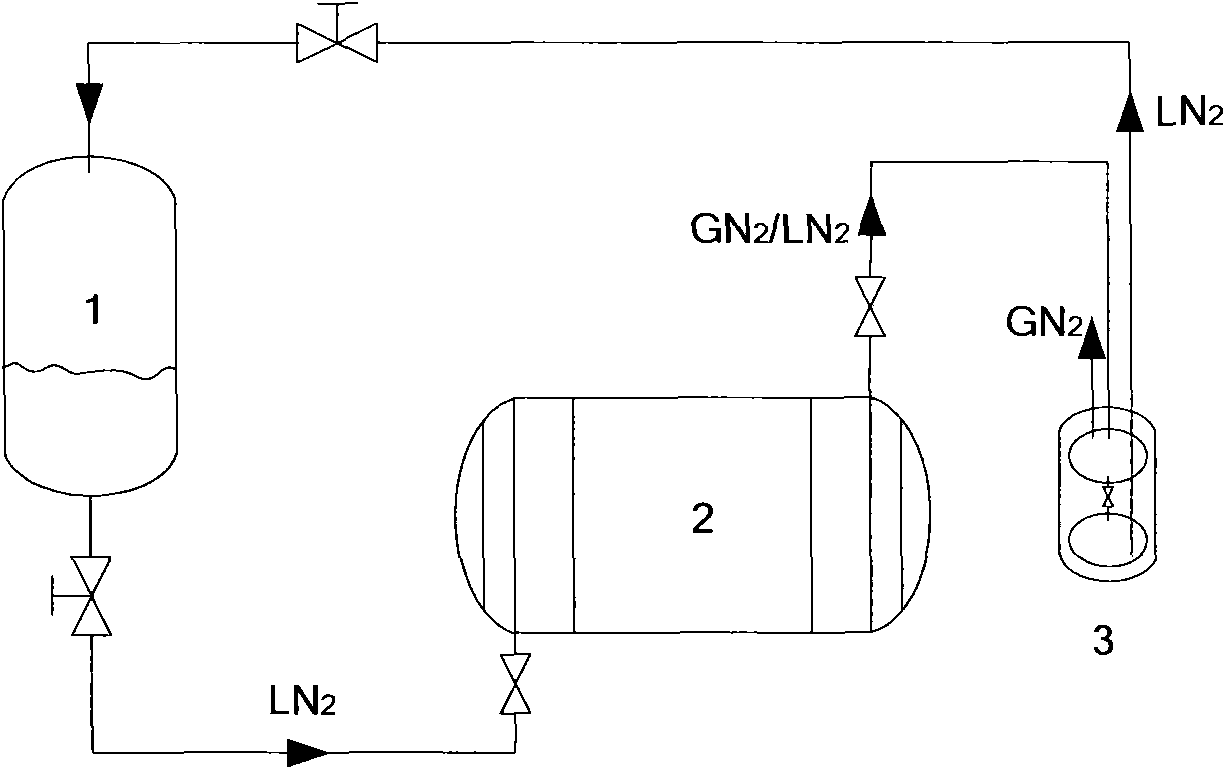

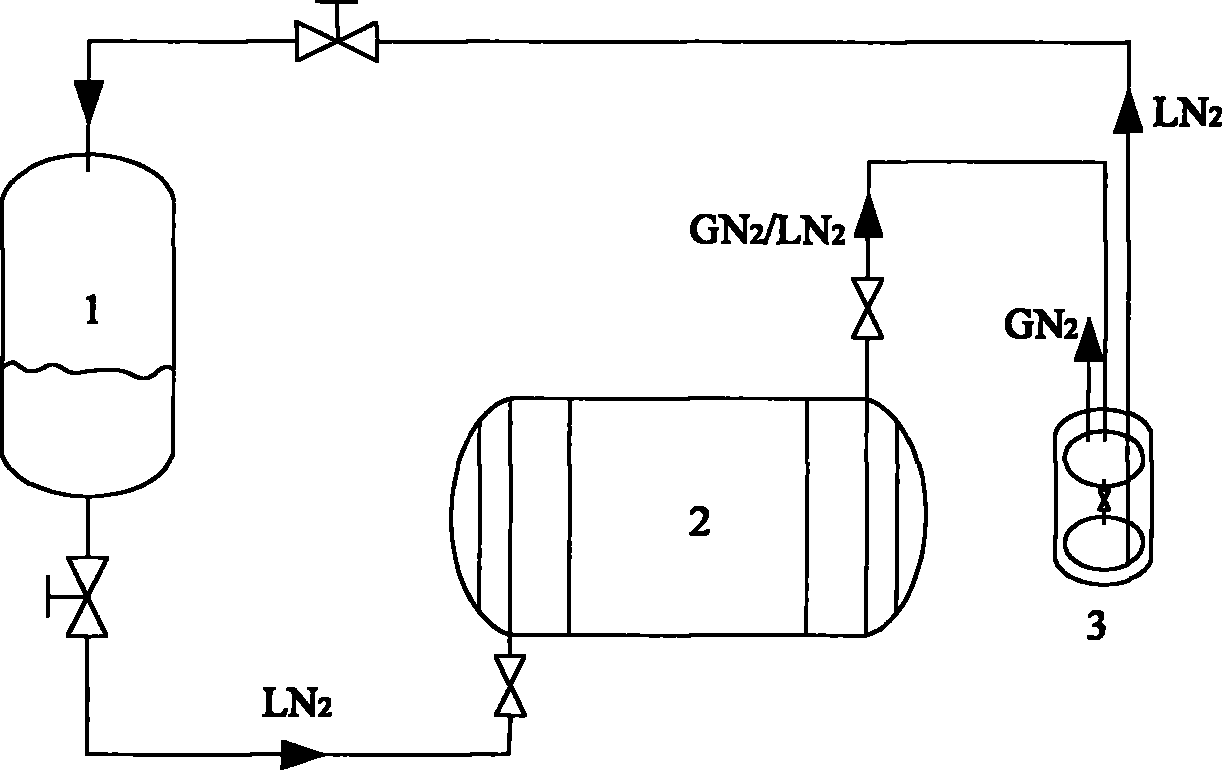

[0011] Due to the low cost performance of recovery, the existing technology usually discharges the gas-liquid two-phase nitrogen at the outlet of the system directly to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com