Treatment method of hydrazine hydrate byproduct sodium chloride brine

A technology of sodium chloride brine and treatment method, which is applied in the field of by-product treatment in the production of hydrazine hydrate by ketazine method, can solve the problems of landfill or transfer of pollution, high content of organic matter, difficulty in popularization and application, etc., and achieves low treatment cost, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

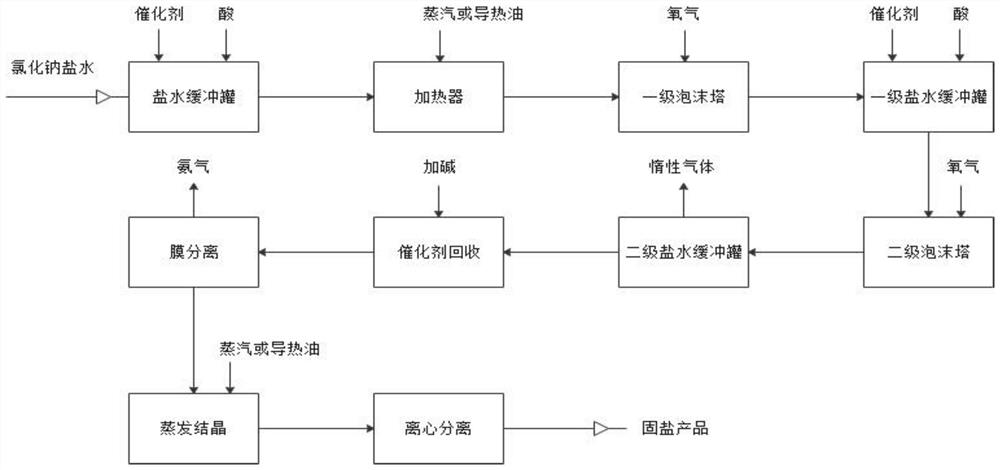

Method used

Image

Examples

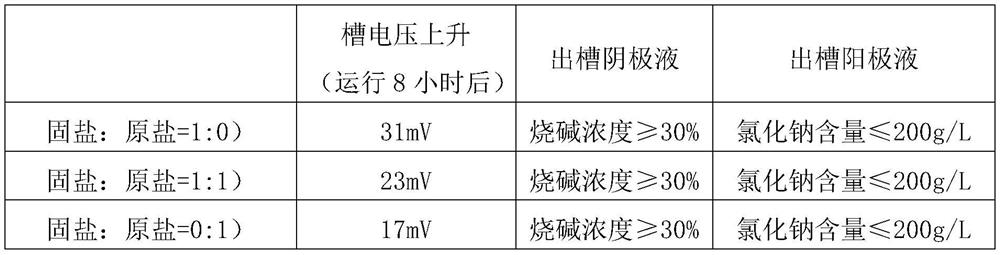

Embodiment 1

[0025] The hydrazine hydrate by-product sodium chloride brine treated in this embodiment has a COD content of 15000 ppm and an ammonia content of 800 ppm.

[0026] S1. In the brine buffer tank, add hydrochloric acid with a mass ratio of 1:1 to the hydrazine hydrate by-product sodium chloride brine, adjust the brine pH=3.6, and add 0.1% ferric chloride of the brine quality to the brine;

[0027] S2. The adjusted brine is pumped into the heater to exchange heat with the heating medium, and the brine is heated to 220-230°C;

[0028] S3. The heated brine enters the feed port at the top of the first-stage foam tower and fully contacts with the oxygen from bottom to top. A high-efficiency gas distributor is used to realize the uniform dispersion and reaction of oxygen in the sodium chloride brine, and the organic matter in the brine Converted to acetic acid and sodium acetate, the amount of oxygen introduced is based on the COD value of sodium chloride brine, and the ratio of oxygen...

Embodiment 2

[0033] The hydrazine hydrate by-product sodium chloride brine treated in this embodiment has a COD content of 10000 ppm and an ammonia content of 1000 ppm.

[0034] S1, in the brine buffer tank, add sulfuric acid with a mass ratio of 1:1 to the hydrazine hydrate by-product sodium chloride brine, adjust the brine pH=3.8, and add 0.08% iron sulfate of brine quality to the brine;

[0035] S2. The adjusted brine is pumped into the heater to exchange heat with the heating medium, and the brine is heated to 220-230°C;

[0036] S3. The heated brine enters the feed port at the top of the first-stage foam tower and fully contacts with the oxygen from bottom to top. A high-efficiency gas distributor is used to realize the uniform dispersion and reaction of oxygen in the sodium chloride brine, and the organic matter in the brine Converted to acetic acid and sodium acetate, the amount of oxygen introduced is based on the COD value of sodium chloride brine, and the ratio of oxygen demand t...

Embodiment 3

[0041] The hydrazine hydrate by-product sodium chloride brine treated in this embodiment has a COD content of 2000 ppm and an ammonia content of 800 ppm.

[0042] S1, in the brine buffer tank, add nitric acid and formic acid with a mass ratio of 1:1 to the hydrazine hydrate by-product sodium chloride brine, adjust the brine pH=3.9, and add 0.05% ferric nitrate of the brine quality to the brine;

[0043] S2. The adjusted brine is pumped into the heater to exchange heat with the heating medium, and the brine is heated to 220-230°C;

[0044] S3. The heated brine enters the feed port at the top of the first-stage foam tower and fully contacts with the oxygen from bottom to top. A high-efficiency gas distributor is used to realize the uniform dispersion and reaction of oxygen in the sodium chloride brine, and the organic matter in the brine Converted to acetic acid and sodium acetate, the amount of oxygen introduced is based on the COD value of sodium chloride brine, and the propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com