Enhanced external pressing hollow fibrous membrane assembly easy to assemble and capable of being integrated

An external pressure hollow fiber, reinforced technology, applied in the field of external pressure hollow fiber membrane treatment system, purification equipment, drinking water production process, can solve the problem of reducing the service life of the membrane module membrane treatment system, affecting the adaptability, impact resistance, and ease of use. Damage to the membrane wire and other problems, to achieve the effect of small investment, flexible use, and avoidance of membrane wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

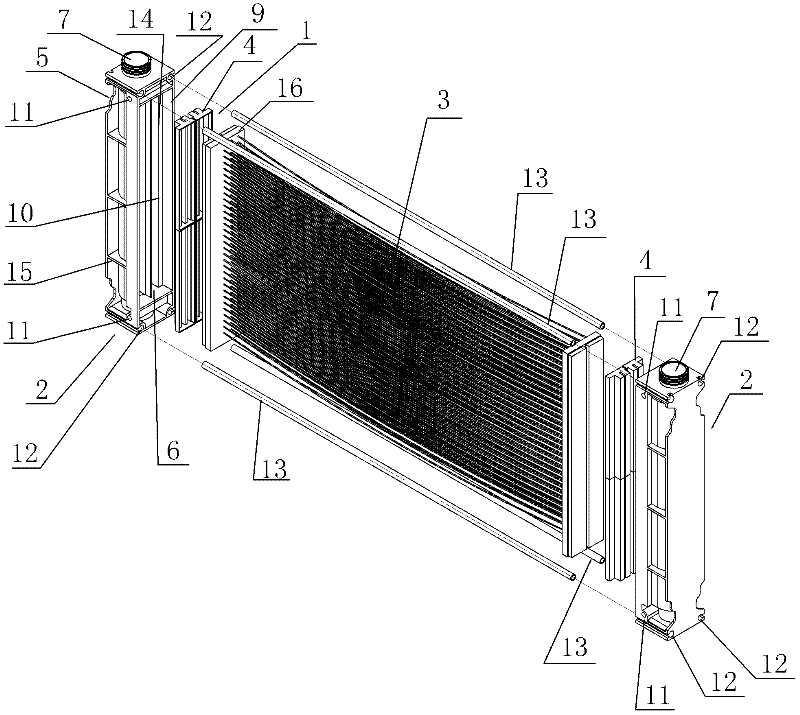

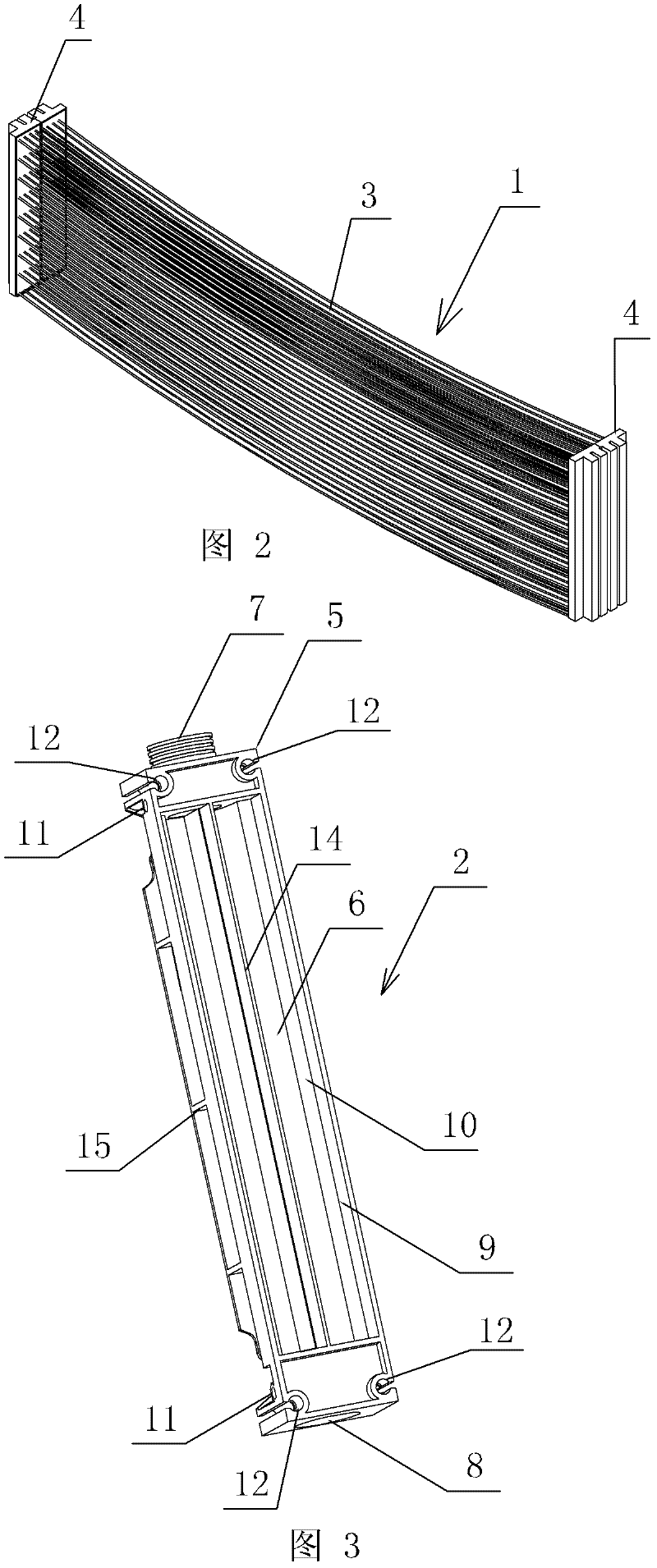

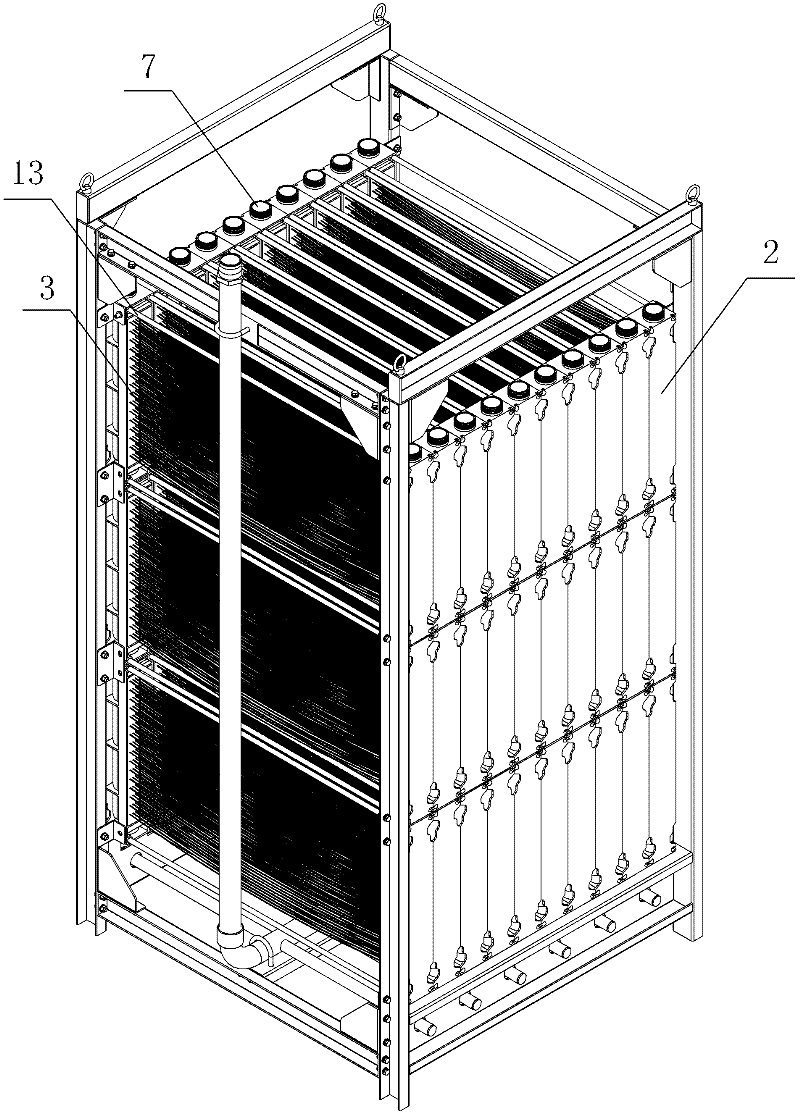

[0039] Example: see attached Figure 1-4 As shown, an easily assembled and integrated reinforced external pressure hollow fiber membrane module includes four membrane modules 1 and two water collection devices 2;

[0040] The membrane module 1 is composed of several (thousands) hollow fiber membranes 3 and two sealed containers 4. The hollow fiber membranes 3 have hollow lumens, and microfiltration holes are arranged on the walls of the hollow lumens. One end of the membrane tow that several hollow fiber membranes 3 are formed is packaged in a film-sealing container 4 by a colloid block 16, and the other end of the membrane tow is packaged in another film-sealing container 4 by a colloid block 16. The hollow fiber membranes 3 at both ends of the tow are exposed at the ends of the two film-sealing containers 4;

[0041] The water collecting device 2 is a cylindrical housing 5, the housing 5 has a cylindrical hollow cavity 6, the cylindrical hollow cavity 6 forms a water flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com