A kind of mems supercapacitor and preparation method thereof based on high dielectric constant film

A high dielectric constant, supercapacitor technology, used in the manufacture of hybrid/electric double layer capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of low energy density of electrostatic supercapacitors, achieve improved performance, good temperature stability, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

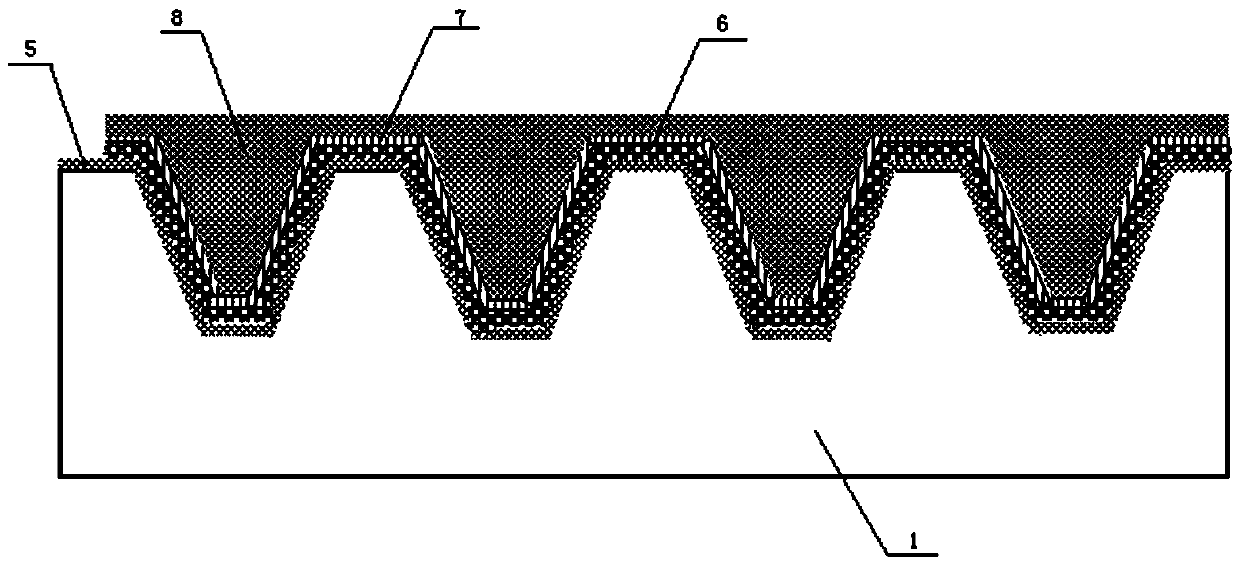

[0038] A MEMS supercapacitor based on a high dielectric constant film, including a silicon wafer, a three-dimensional groove array 4 is etched on the silicon wafer, heavily doped phosphorus elements are used as the lower electrode layer 5 on the silicon wafer with the etched structure, and the heavily doped A CCTO-0.1MTO dielectric thin film layer 6 is formed on the substrate by liquid phase deposition, and a metal gold layer is sputtered on the dielectric thin film layer 6 as the upper electrode layer 7, and the lower electrode layer 5 is partially exposed outside the upper electrode layer 7, three-dimensional The micropores of the groove structure 4 are filled with copper conductive paste 8 .

[0039] The above-mentioned preparation method based on the MEMS supercapacitor of high dielectric constant film, comprises the steps:

[0040]S1: Mix 0.06mol of Cu(NO3)2·3H2O, 0.02mol of Ca(CH3COO)2·H2O, 0.08mol of Ti(OC4H9)4 and 0.002mol of Mg(CH3COO)2·4H2O in ethylene glycol , drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com