Device for processing powder for a device for manufacturing a three-dimensional object and device for manufacturing a three-dimensional object

A technology for three-dimensional objects and powders, applied in mixers with rotating stirring devices, manufacturing, chemical/physical processes, etc., can solve problems such as damage to powders, achieve low structural strength, reduce use, and reduce material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

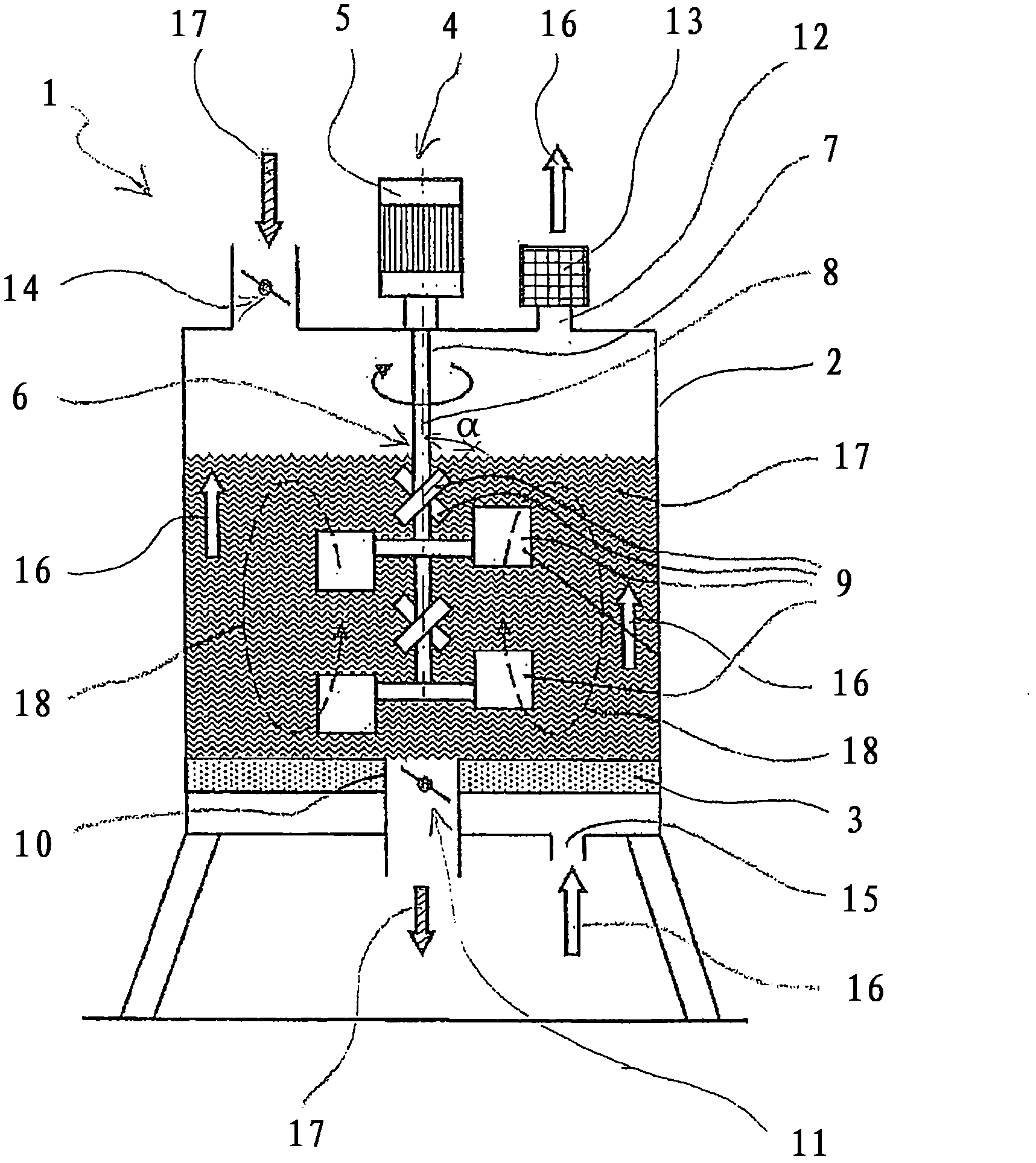

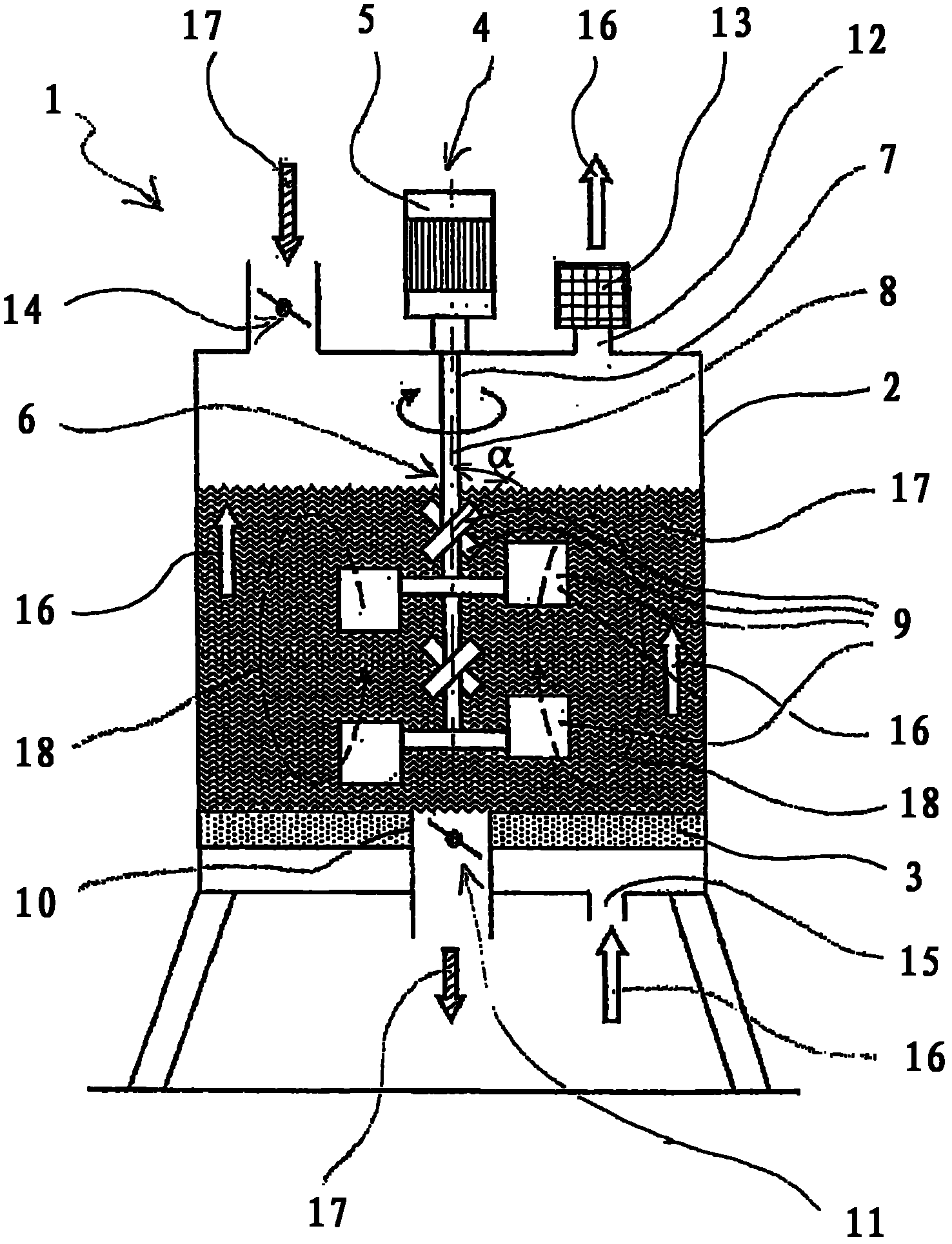

[0020] figure 1 A device for mixing powder 17 is indicated. The device has a container 2 which has a bottom and is provided with a fluid-permeable plate 3 in the area of its bottom. Furthermore, the device 1 is equipped with a stirring device 4 . In the region of its base, the container 2 is provided with an inflow opening 15 through which a fluid 16 can flow into the container 2 . The container 2 has a cover at the upper end, which is provided with a powder inlet opening 14 and a fluid outlet opening 12, on which a filter element 13 is mounted. The bottom of the container 2 is here centrally provided with an outlet opening 11 which can be closed. The container has a horizontal cross-section suitable for good mixing of the powder. The horizontal cross-section is circular in this embodiment, but may also be polygonal, elliptical, etc. in other embodiments. Alternatively, the container 2 has a fluid permeable bottom which is somewhat funnel-shaped.

[0021] The fluid-per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com