Speed reduction type hub driving system with function of power shock absorption

A wheel-side drive and dynamic vibration absorption technology, which is applied in the direction of power devices, brakes, motion deposition, etc., can solve the problems that the mass of dynamic vibration absorbers should not be too large, increase the curb weight of the whole vehicle, and have limited vibration absorption, so as to improve the vertical performance , low manufacturing cost and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

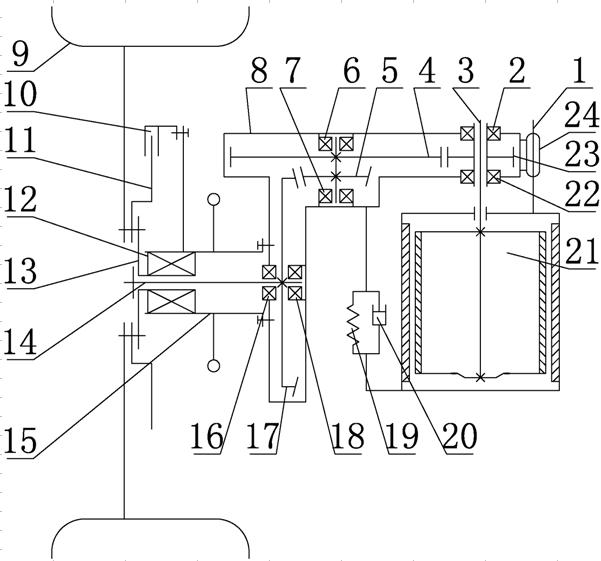

[0041] Please refer to the accompanying drawings to further describe the present invention.

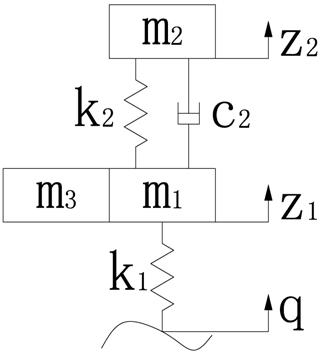

[0042] figure 1 It is a two-degree-of-freedom vibration model diagram of a traditional wheel-driven electric vehicle with a 1 / 4 vehicle. The motor mass m3 is the unsprung mass.

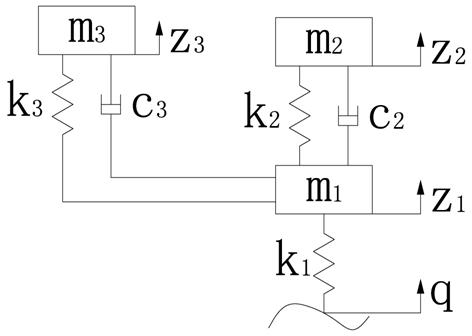

[0043] figure 2 This is a three-degree-of-freedom vibration model diagram of a 1 / 4 vehicle equipped with a vibration absorber according to the present invention. The vibration model of the decelerating wheel drive system with dynamic vibration absorption can be simplified as follows: figure 2 , Where m2 is 1 / 4 of the body mass, m1 is the unsprung mass, which mainly includes wheels, rims 9, braking system rotating components 11, braking system non-rotating components 10, half shafts 14, steering knuckles 15, and internal flowers Key first-stage reduction small cylindrical gear 23, first-stage reduction large cylindrical gear 4, second-stage reduction small bevel gear 5, second-stage reduction large bevel gear 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com