Gyro directional platform for pantograph of electric locomotive

A technology for electric locomotives and directional platforms, which is applied to electric vehicles, collectors, vehicle components, etc., can solve the problems of inability to operate, and achieve the effect of improving the quality of current receiving and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

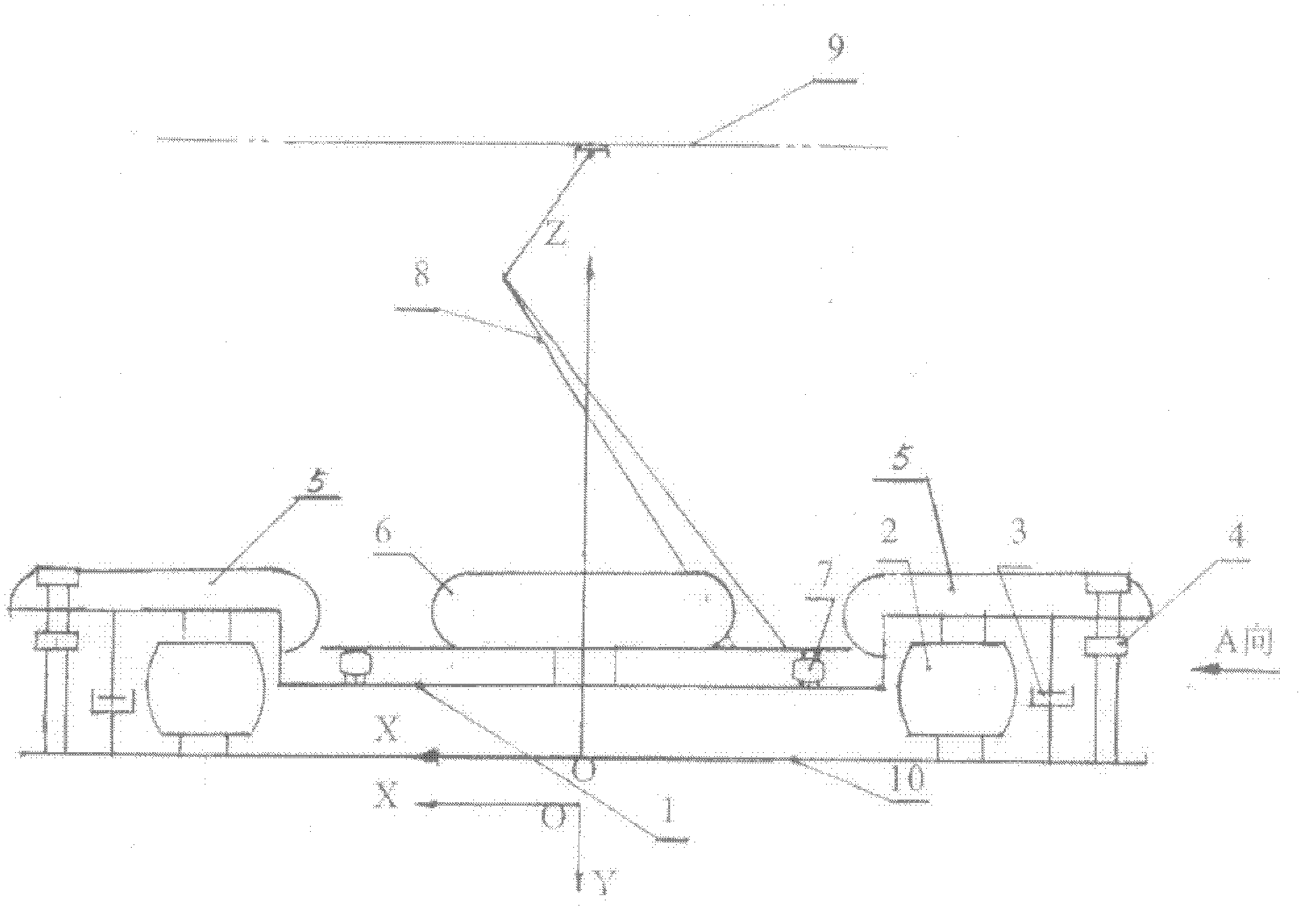

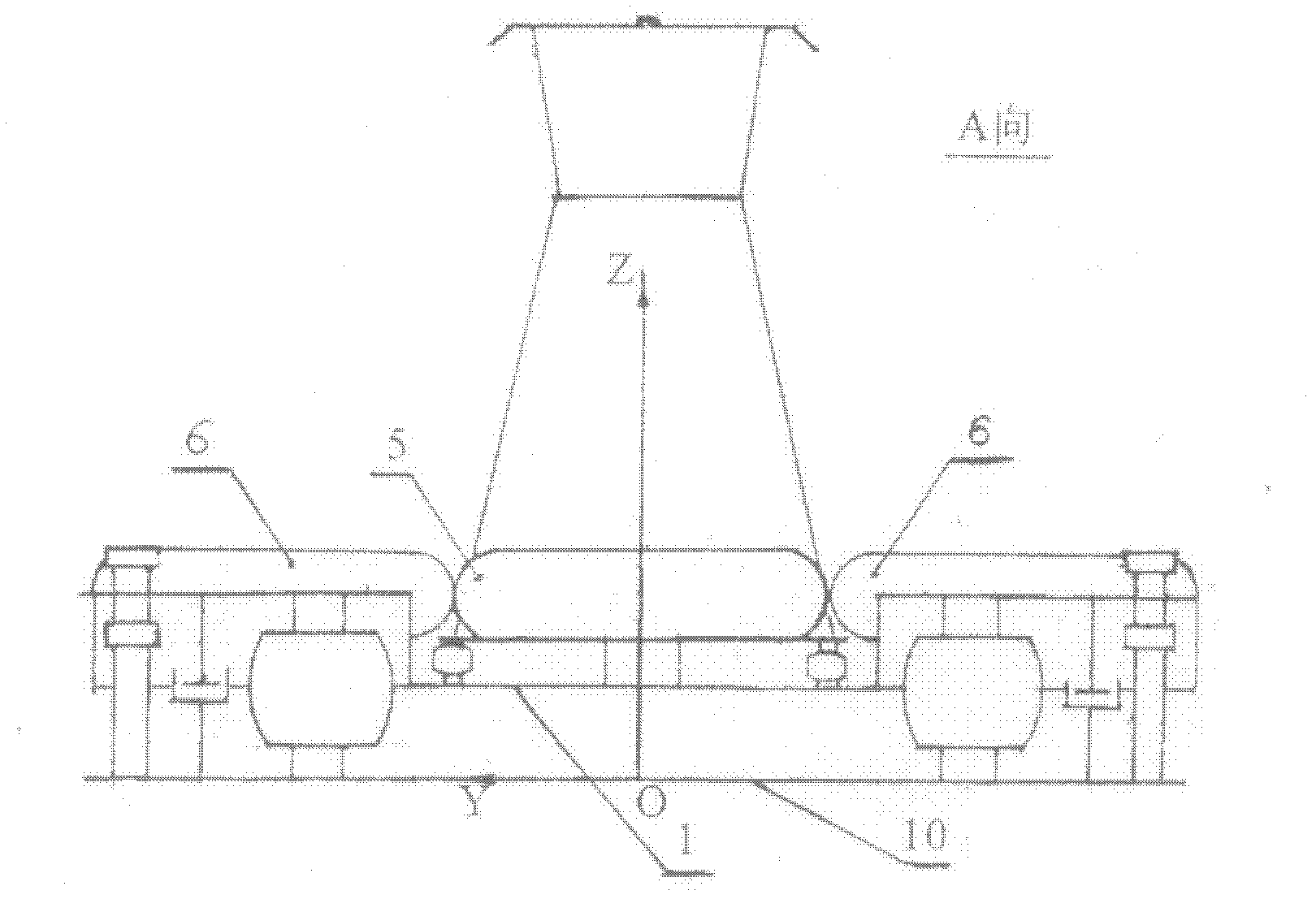

[0009] The present invention will be further described below with reference to the accompanying drawings: Cartesian coordinate axes set for convenience of description: X direction is the forward direction of the locomotive, Z direction is vertically upward, and XOY is the coordinate axis seen downward from the positive direction of the Z axis .

[0010] The gyro directional platform is composed of two parts, and the substrate is made into a zigzag shape to save space. The first part is a damping platform, which is installed on the four corners of the base plate 1, symmetrical to the X-axis and Y-axis, and consists of four air springs 2, four hydraulic shock absorbers 3 and four stoppers 4 , their upper ends are installed on the base plate, and their lower ends are installed on the roof plate 10 of the electric locomotive, and they are arranged in the direction of crossing lines at four corners. The limiter 4 limits the movement of the substrate 1 within a safe range. The adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com