Method for preparing porous carbon micron tube from catkin, poplar seed or phoenix tree seed as raw material

A technology of micron tubes and porous carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of limited application and small specific surface area, and achieve good catalytic oxygen reduction reaction performance and capacitance characteristics, catalytic oxygen reduction good response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

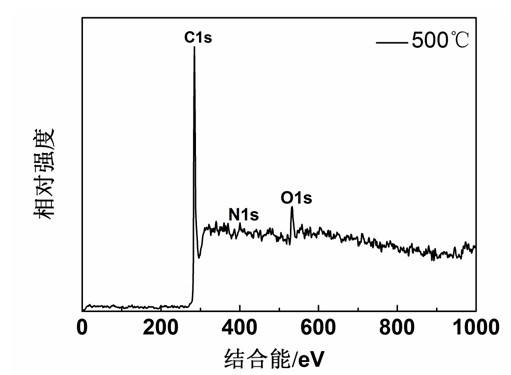

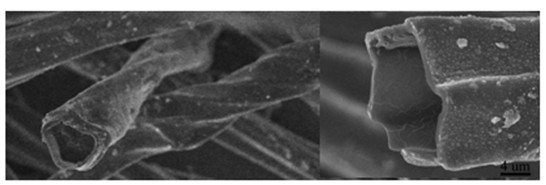

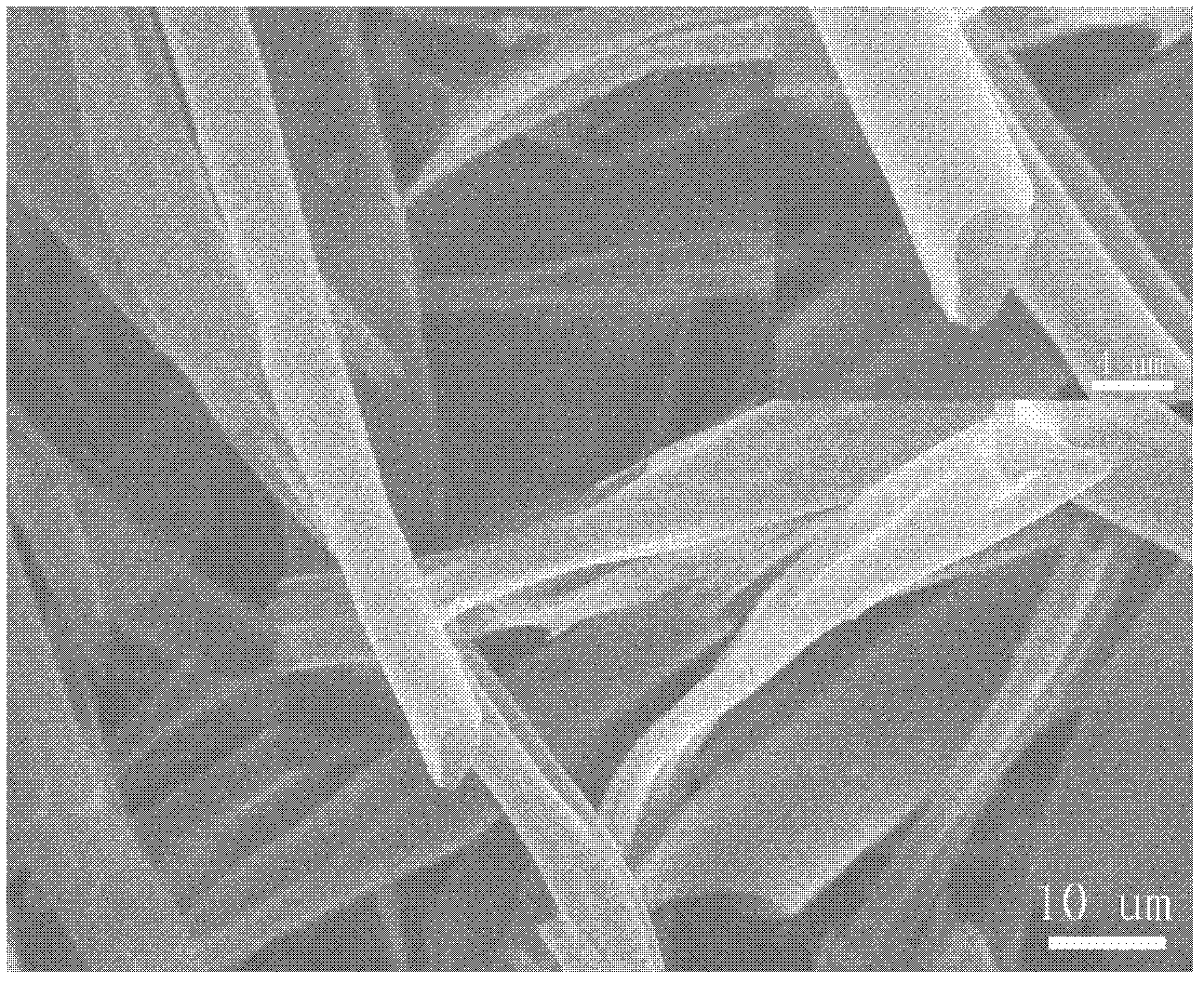

[0047] Example 1: Using the chemical activation method, poplar catkins were placed in a tube furnace and carbonized under Ar atmosphere, and then ZnCl 2 After soaking the solution for 10-20 h, place it in the center of a tube furnace, heat it up to 500-2000 °C in an Ar atmosphere, activate it for 0.5-10 h, and then naturally cool it to room temperature in an Ar atmosphere, and finally wash and dry it to obtain a microporous carbon micron. Tube. Using the physical activation method, poplar catkins are placed in a tube furnace and carbonized for a period of time under Ar atmosphere, then the temperature is raised to 800-2000 °C, and then CO 2 Gas activation for 0.5-10 h, and finally cooled to room temperature under Ar atmosphere to obtain the product. Using the chemical physical activation method, the product obtained by the chemical activation method is placed in the middle of the tube furnace, and then CO 2 Gas treatment for 10-60 min, cooling to room temperature to obtai...

Embodiment 2

[0048] Embodiment 2: Using the chemical activation method, poplar catkins were placed in a tube furnace and carbonized under an Ar atmosphere, then impregnated with a KOH solution for 10-20 h, placed in the center of the tube furnace, and heated to 500-2000 °C under an Ar atmosphere. After activation for 0.5-10 h, it was naturally cooled to room temperature under Ar atmosphere, and finally the porous carbon microtubes were washed and dried. Using the physical activation method, poplar catkins are placed in a tube furnace and carbonized for a period of time under Ar atmosphere, then the temperature is raised to 800-2000 °C, and then CO 2 Gas activation for 0.5-10 h, and finally cooled to room temperature under Ar atmosphere to obtain the product. Using the chemical physical activation method, the product obtained by the chemical activation method is placed in the middle of the tube furnace, and then CO 2 Gas treatment for 10-60 min, cooling to room temperature to obtain mes...

Embodiment 3

[0049] Embodiment 3: Using the chemical activation method, poplar catkins were carbonized in a tube furnace under an Ar atmosphere, and then treated with H 3 PO 4 After soaking the solution for 10-20 h, place it in the center of a tube furnace, heat it up to 500-2000 °C in an Ar atmosphere, activate it for 0.5-10 h, then cool it to room temperature naturally in an Ar atmosphere, and finally wash and dry the porous carbon micron Tube. Using the physical activation method, poplar catkins are placed in a tube furnace and carbonized for a period of time under Ar atmosphere, then the temperature is raised to 800-2000 °C, and then CO 2 Gas activation for 0.5-10 h, and finally cooled to room temperature under Ar atmosphere to obtain the product. Using the chemical physical activation method, the product obtained by the chemical activation method is placed in the middle of the tube furnace, and then CO 2 Gas treatment for 10-60 min, cooling to room temperature to obtain mesoporo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com