Manganese dioxide film electrode with double 3-dimensional (3D) structures and preparation method thereof

A technology of manganese dioxide and thin-film electrodes, which is applied in the field of capacitors, can solve the problems of insufficient utilization of thin-film electrodes, achieve high utilization and specific capacity, increase contact area, and achieve good capacitance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

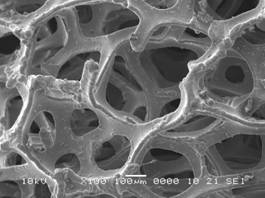

[0023] will be like figure 1 1 part of nickel foam with obvious 3D structure is put into acetone, 0.1M hydrochloric acid and deionized water successively for cleaning, and it is ready for use after completion; 0.06 part of sodium lauryl sulfate is dissolved in 10 parts of deionized water, and 0.5 parts of potassium permanganate were dissolved in 20 parts of deionized water; 69.4 parts of deionized water and the above two aqueous solutions were added to the reactor, and then the cleaned foam nickel was also placed in the reactor; the reactor was sealed and placed Put it into an oven at 180° C. for 10 hours; after cooling naturally, take out the nickel foam and wash it to obtain the thin film electrode of the present invention.

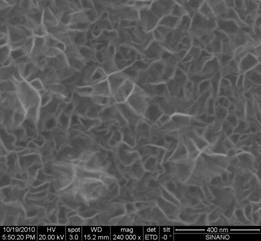

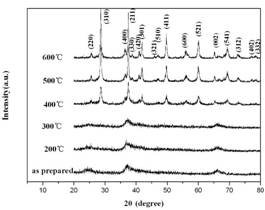

[0024] Scanning electron microscope analysis was carried out on the surface of the film, and the results are detailed in figure 2 , it was found from the results that it has an obvious 3D structure. After the film was calcined at 280°C, X-ray analysi...

Embodiment 2

[0026] will be like figure 1 As shown, 2 parts of nickel foam with obvious 3D structure were put into acetone, 0.1M hydrochloric acid and deionized water to clean successively, and then used after completion; 0.1 part of sodium lauryl sulfate was dissolved in 10 parts of deionized water, and 1 part of potassium permanganate is dissolved in 20 parts of deionized water; 69 parts of deionized water and the above two aqueous solutions are added to the reactor, and then the cleaned foam nickel is also placed in the reactor; the reactor is sealed and placed Put it into an oven at 100°C to react for 24 hours; after blowing and cooling, take out the nickel foam and wash it to obtain the thin film electrode of the present invention.

[0027] The surface of the film was analyzed by scanning electron microscopy, and it was found that it had an obvious 3D structure. After the film was calcined at 300°C, X-ray analysis showed that it was α-MnO 2 . The prepared thin film electrode was pr...

Embodiment 3

[0029] will be like figure 1 As shown, 4 parts of foamed nickel with obvious 3D structure are put into acetone, 0.1M hydrochloric acid and deionized water successively for cleaning, and stand-by after completion; 0.15 parts of sodium lauryl sulfate are dissolved in 10 parts of deionized water, and 1.8 parts of potassium permanganate were dissolved in 20 parts of deionized water; 67 parts of deionized water and the above two aqueous solutions were added to the reactor, and then the cleaned foam nickel was also placed in the reactor; the reactor was sealed and placed Put it into an oven at 240° C. for 2.5 hours; after cooling naturally, take out the nickel foam and wash it to obtain the thin film electrode of the present invention.

[0030] The surface of the film was analyzed by scanning electron microscopy, and it was found that it had an obvious 3D structure. After the film was calcined at 300°C, X-ray analysis showed that it was α-MnO 2 . The prepared thin film electrode wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com