Fast biofilm formation device of suspended filler and sequencing batch biofilm reactor

A technology of suspended filler and biological reaction tank, which is applied in the field of water treatment, can solve the problems of unsatisfactory film-hanging effect, unfavorable maintenance, update and management, and unchanged use and maintenance, so as to achieve convenient daily maintenance and easy promotion and use , Easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

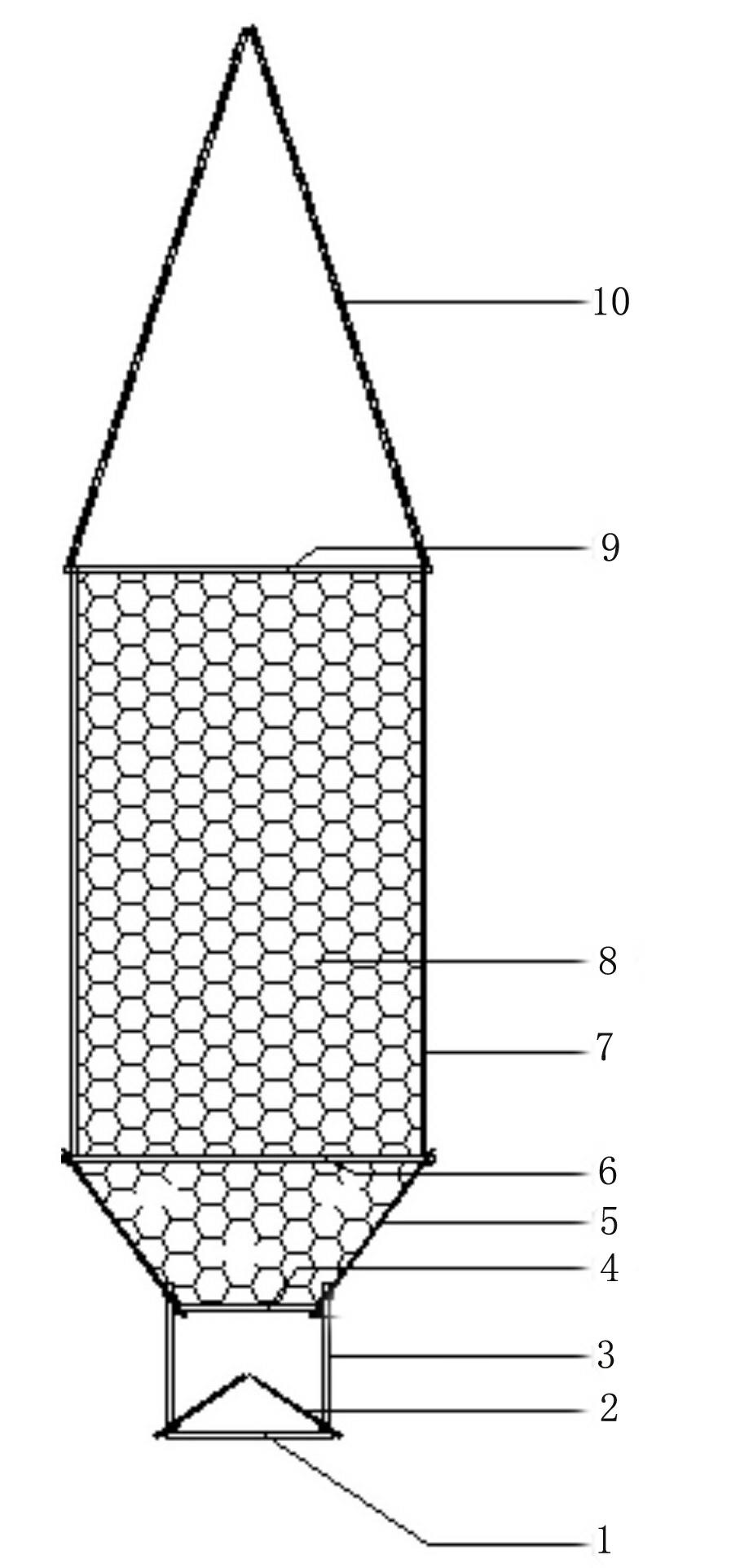

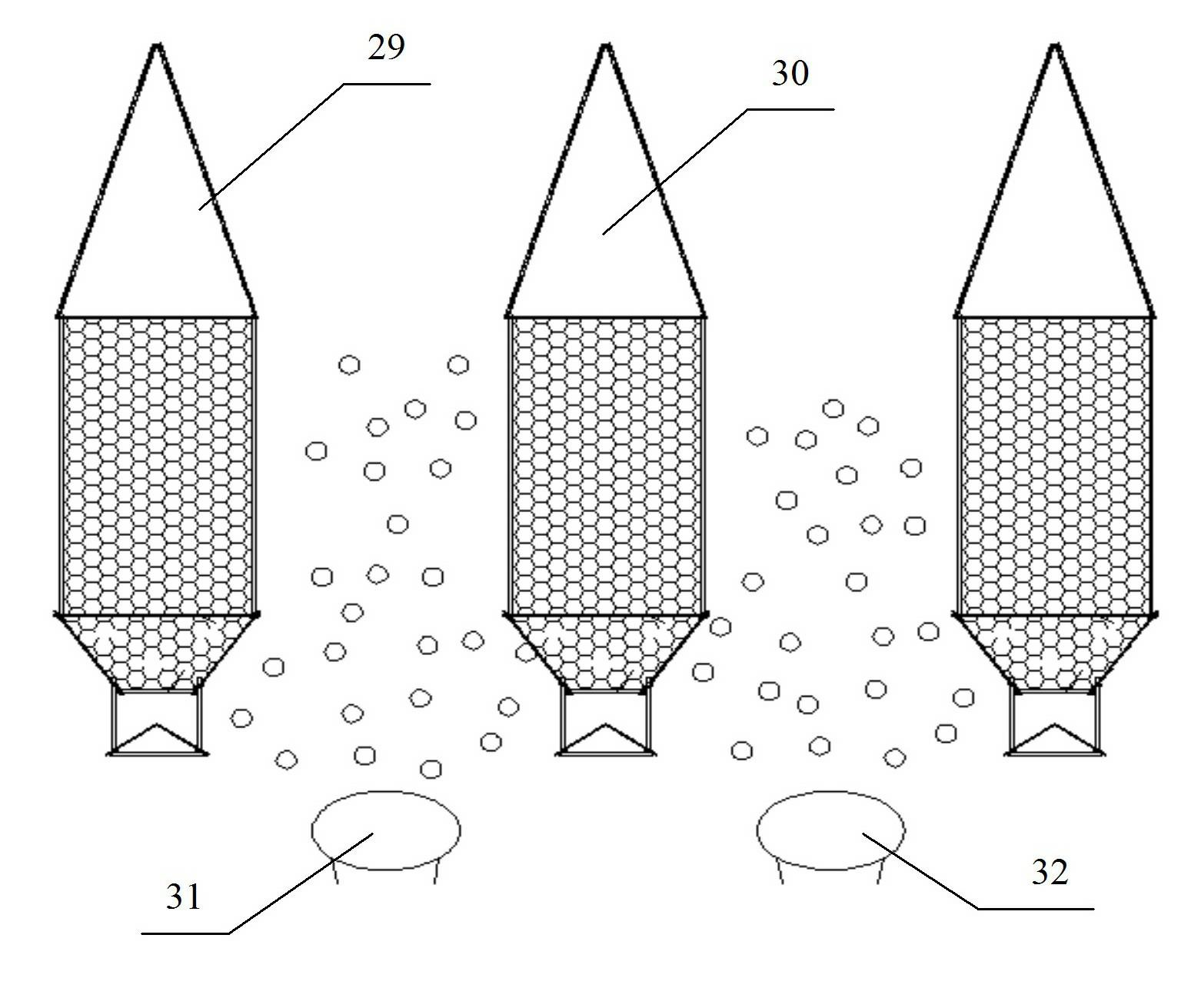

[0019] Example 1 A kind of suspended filler rapid film-hanging device, see figure 1 , figure 2 , including a stuffing basket composed of a skeleton and a wall net, two baffles 5 arranged obliquely are symmetrically distributed at the bottom of the stuffing basket, and the included angle between the baffles 5 and the horizontal plane is 55°, and an opening is installed below the stuffing basket. The lower V-shaped fender 3, the top angle of the V-shaped fender 3 is 105 °, and the basic skeleton of the packing basket consists of two top edge bars 9, four frame edge bars 9, two lower support bars 6, two A base bar 4 and four connecting bars 3 are formed, and then wrapped with a wall net 8 to form a space for holding biological fillers, see figure 1 , figure 2 . Suspension rope 10 is also arranged on the film hanging device. After a certain amount of packing is placed in the packing basket, it is suspended and fixed on the transverse stay cable 13 in the biological reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com