Preparation method for corundum baddeleyite eutectoid composite nonswirl nozzle inner layer

A sizing nozzle and baddeleyite technology, which is applied in the field of preparation of corundum baddeleyite eutectoid composite sizing nozzle inner layer, can solve the problems of high melting point, high corrosion resistance, and the increase in the amount of chromium-containing industrial waste , increase in production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

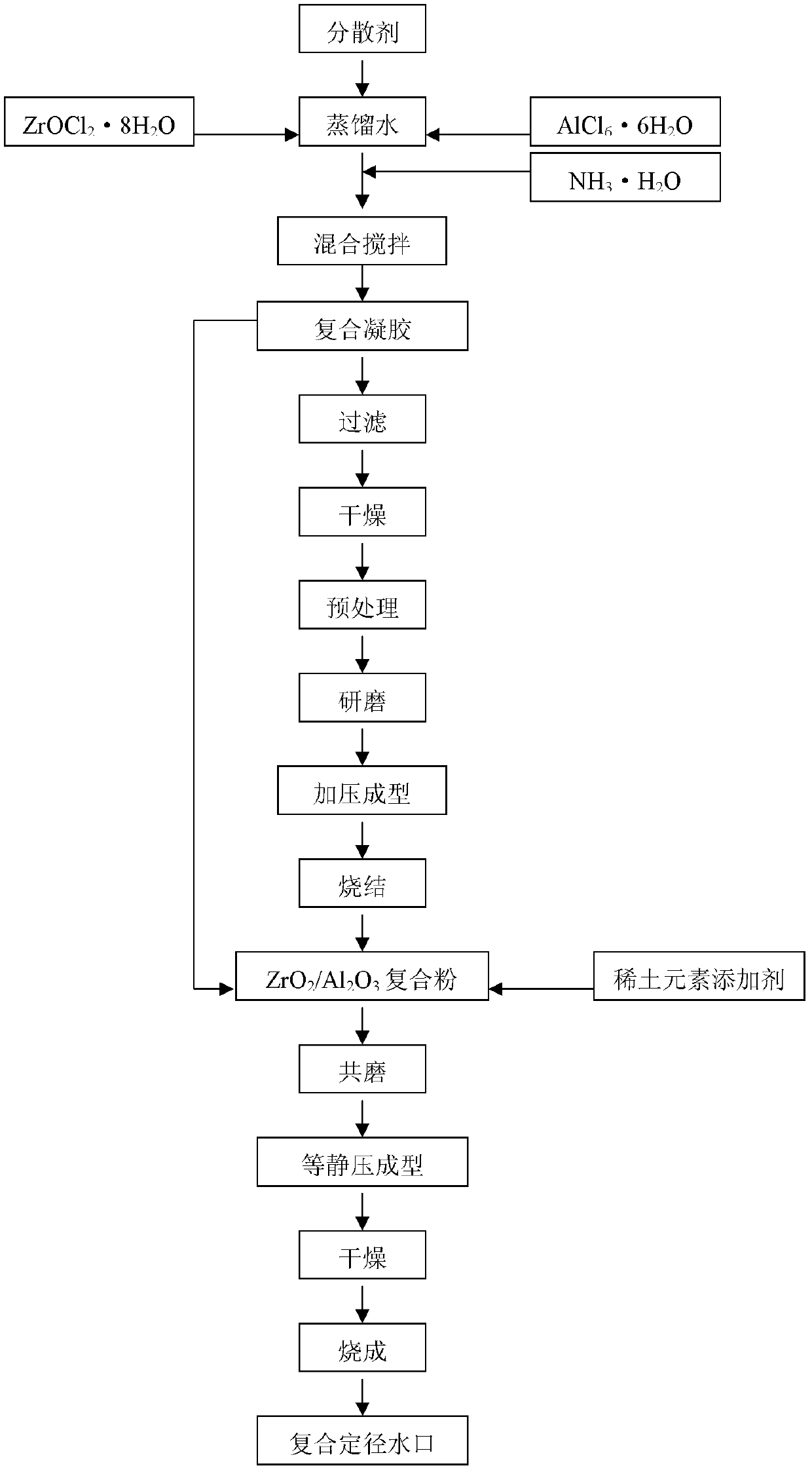

Method used

Image

Examples

Embodiment 1

[0026] Step 1, get ZrOCl by weight percentage 2 .8H 2 O:Al(NO 3 ) 3 .9H 2 O: Y (NO 3 ) 3 =70:30:3, prepare mother liquor, add dispersant (TH-908 ceramic dispersant) of 1.2% of the total weight of material, NH4(OH) positive titration, stir until PH=7-10, obtain gel, age 12h; Vacuum filtration at -0.095MPa, washing with deionized water until silver nitrate cannot detect Cl - up to; then react at 500°C for 2 hours, then raise the temperature to 700°C, react for 10 hours, degumming after the reaction is completed, that is, ZrO 2 = 45±1% ZrO 2 -Al 2 o 3 Compound powder. The particle sizes are 1 μm to 3 μm, 5 μm to 15 μm, and 30 μm to 90 μm.

[0027] Step 2, the above-mentioned ZrO with different average particle diameters 2 -Al 2 o 3 The composite powder is graded, and its composition is as follows: 30% of the particle size is 1 μm to 3 μm, 15% of the particle size is 5 μm to 15 μm, and 55% of the particle size is 30 μm to 90 μm.

[0028] Step 3, according to the abo...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is: the ZrO in the step 3 2 -Al 2 o 3 The gradation composition of the composite powder is 90% by mass ratio, 10% of rare earth element additives, and co-milled for 24 hours; other steps are the same as in Example 1, and the corundum baddeleyite eutectoid content is also obtained ≥ 90%, and the service life can reach 23 hours The inner layer of the composite sizing nozzle.

Embodiment 3

[0032] The difference between this embodiment and embodiment 1 is: the ZrO in the step 3 2 -Al 2 o 3 The gradation composition of the composite powder is 95% by mass ratio, 5% of rare earth element additives, and co-milled for 36 hours; other steps are the same as in Example 1, and the corundum baddeleyite eutectoid content is also obtained ≥ 90%, and the service life can reach 23 hours The inner layer of the composite sizing nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com