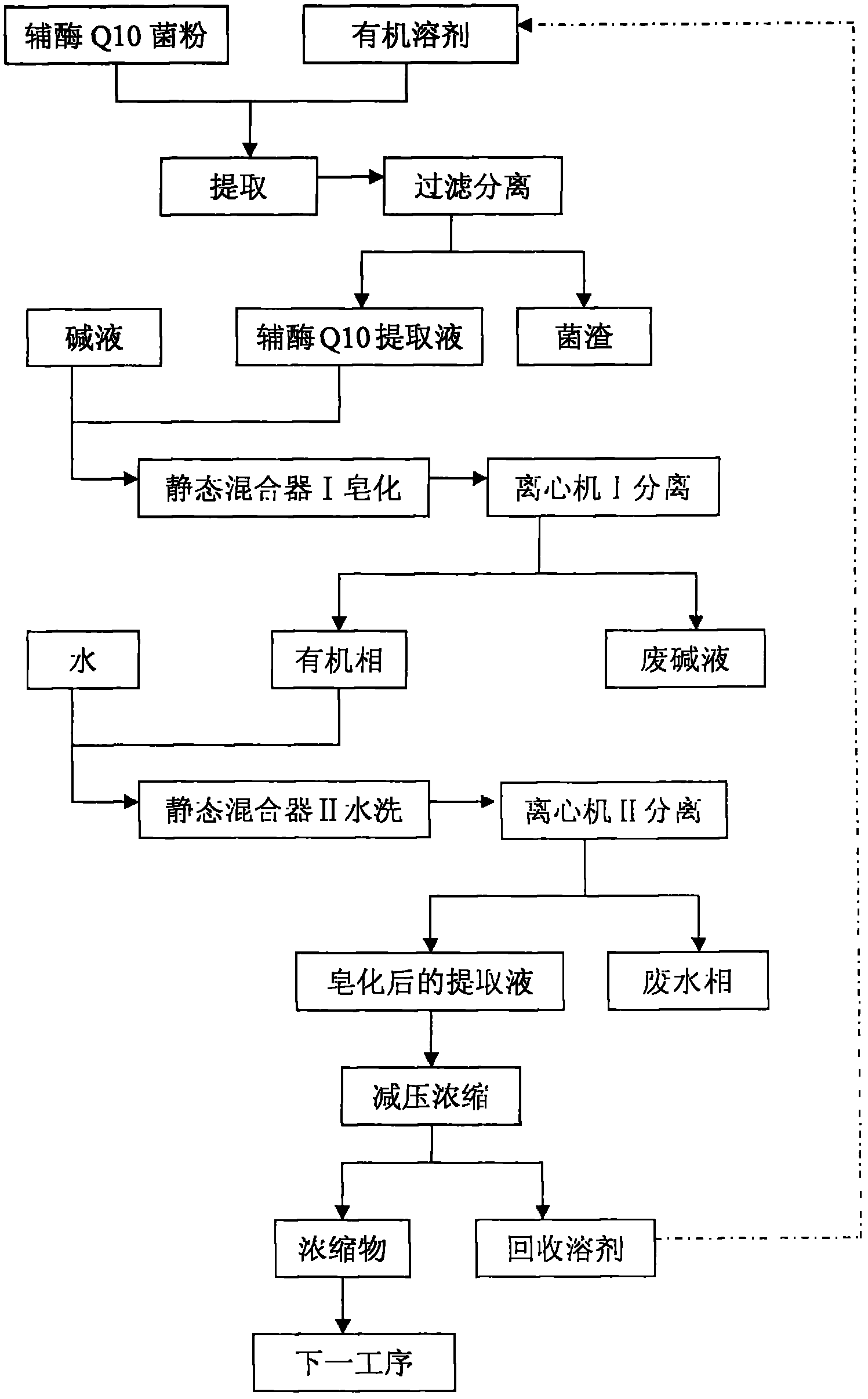

Method for saponifying coenzyme Q10 extracting solution

An extraction solution and coenzyme technology, applied in organic chemistry, quinone separation/purification, etc., can solve the problems of easy emulsification and inability to continue automatic operation, etc., achieve the effect of reducing impurity content, reducing labor intensity of employees, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1000Kg coenzyme Q10 bacterial powder, add 4000L n-hexane to extract three times at 30°C, filter and separate, combine the extracts, a total of 3400L, the coenzyme Q10 content of the extract is 8.03mg / ml, and the coenzyme Q10 content of the extract concentrate was 42.34%. The extract and NaOH solution (1.5mol / L) were mixed with 1m 3 / h and 0.5m 3 The flow rate of / h enters the static mixer I for saponification at the same time, and the mixed solution after the static mixer I enters the disc centrifuge I for centrifugation (centrifugal speed 8000r / min), and obtains 3310L of light components (organic phase). Phase and water are separated by 1m 3 / h and 0.5m 3 The flow rate of / h enters the static mixer II for washing at the same time, and the mixed solution after passing through the static mixer II enters the disc centrifuge II for centrifugation (centrifugal speed 8000r / min) to obtain the light component (organic phase, that is, after saponification) extract) 330...

Embodiment 2

[0025] Take 1000Kg coenzyme Q10 bacterial powder, add 4000L n-hexane to extract three times at 30°C, filter and separate, combine the extracts, a total of 3380L, the measured coenzyme Q10 content of the extract is 8.13mg / ml, and the coenzyme Q10 content of the extract concentrate was 42.88%. The saponification and water washing methods of the extract were the same as in Example 1 except that KOH was used instead of NaOH. Finally, 3290 L of the saponified extract was obtained, and the coenzyme Q10 content of the saponified extract was 8.24 mg / ml. The Q10 content is 58.93%, the saponification yield is 98.65%, and the coenzyme Q10 content of the extract concentrate after saponification increases by 16.05%.

Embodiment 3

[0027] Take 1000Kg coenzyme Q10 bacterial powder, add 4000L n-hexane to extract three times at 30°C, filter and separate, combine the extracts, a total of 3410L, the measured coenzyme Q10 content of the extract is 8.09mg / ml, and the coenzyme Q10 content of the extract concentrate was 41.75%. The extract and NaOH solution (1.5mol / L) were separated at 2m 3 / h and 1m 3 The flow rate of / h enters static mixer 1 simultaneously and carries out saponification, and the mixed liquor after static mixer 1 enters disc centrifuge 1 centrifugal separation (centrifugal speed 8000r / min), obtains light component (organic phase) 3310L, organic Phase and water are separated by 2m 3 / h and 1m 3 The flow rate of / h enters the static mixer II for washing at the same time, and the mixed solution after passing through the static mixer II enters the disc centrifuge II for centrifugation (centrifugal speed 8000r / min) to obtain the light component (organic phase, that is, after saponification) extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com