Preparation method of special battery-grade ferrous oxalate for lithium iron phosphate

A technology of ferrous oxalate and lithium iron phosphate, which is applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of large particles of battery-grade ferrous oxalate, high production cost, low purity, etc., to improve the reaction rate and improve the quality. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

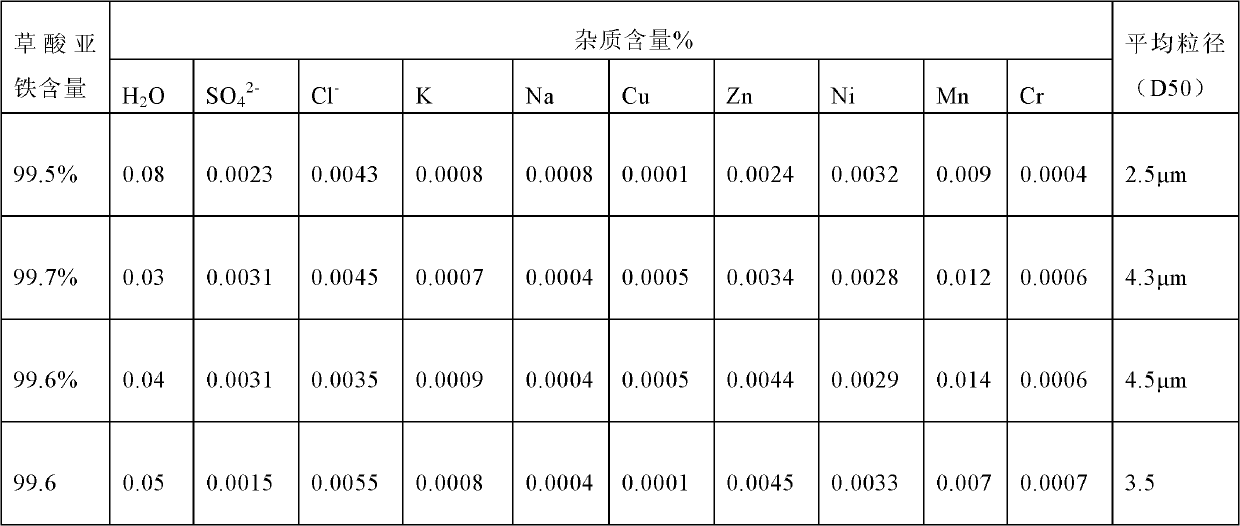

Examples

Embodiment 1

[0030] A. Add 175kg of pure water into the impurity removal kettle, start stirring, and add 350kg of ferrous chloride (the liquid-solid weight ratio is 0.5:1), start heating, and after the water temperature rises to 90°C, add reduced iron powder 1.75 kg, control the pH after the reaction=2.5, stir at constant temperature for 3 hours, obtain ferrous chloride solution, and start pressure filtration;

[0031] B. The ferrous salt solution produced in step A is passed through a group of automatic pressure-maintaining and sealed chamber filter presses (the model is XAMY40 / 800-UK), while filtering to remove metallic impurities, non-metallic impurities and excessive reduced iron powder, Obtain pure ferrous salt solution;

[0032] C. When the ferrous chloride filtrate in step B is clear, open the outlet valve of the filter press, close the return valve of the filter press, and quickly inject the ferrous chloride filtrate into the main reaction kettle; when the filter press is completed...

Embodiment 2

[0037] A. Add 700kg of pure water into the impurity removal kettle, start stirring, and add 350kg of ferrous chloride (liquid-solid weight ratio is 2:1), start heating, and after the water temperature rises to 95°C, add reduced iron powder 4.5 kg, control the pH=3 after the reaction, and stir at a constant temperature for 2 hours to obtain ferrous chloride solution;

[0038] B. The ferrous salt solution produced in step A is passed through a group of automatic pressure-maintaining and sealed chamber filter presses (the model is XAMY40 / 800-UK), while filtering to remove metallic impurities, non-metallic impurities and excessive reduced iron powder, Obtain pure ferrous salt solution;

[0039] C. After the ferrous chloride filtrate of the B step is clear, open the filter press outlet valve, close the filter press return valve, and quickly squeeze the ferrous chloride filtrate into the main reactor; Pour 232.68Kg of dihydrate oxalic acid solid (1.05 times the molar number of ferr...

Embodiment 3

[0044] A. Add 1750kg of pure water into the impurity removal kettle, start stirring, and add 350kg of ferrous chloride (the liquid-solid weight ratio is 5:1), start heating, and after the water temperature rises to 97°C, add reduced iron powder 10.5 kg, control the pH=4 after the reaction, and stir at constant temperature for 1 hour to obtain ferrous chloride solution;

[0045] B. The ferrous salt solution produced in step A is passed through a group of automatic pressure-maintaining and sealed chamber filter presses (the model is XAMY40 / 800-UK), while filtering to remove metallic impurities, non-metallic impurities and excessive reduced iron powder, Obtain pure ferrous salt solution;

[0046] C. After the ferrous chloride filtrate of B step is clear, open the outlet valve of the filter press, close the return valve of the filter press, and quickly squeeze the ferrous chloride filtrate into the main reactor; Add 223.8 kg of oxalic acid dihydrate solid (1.01 times the molar nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com