Polyurea resin compound, preparation method thereof and application thereof in automotive metal glossy lacquer

A technology of polyurea resin and composition, applied in polyurea/polyurethane coatings, coatings, etc., which can solve problems such as application limitations, insufficient number of hydrogen bonds, and poor miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

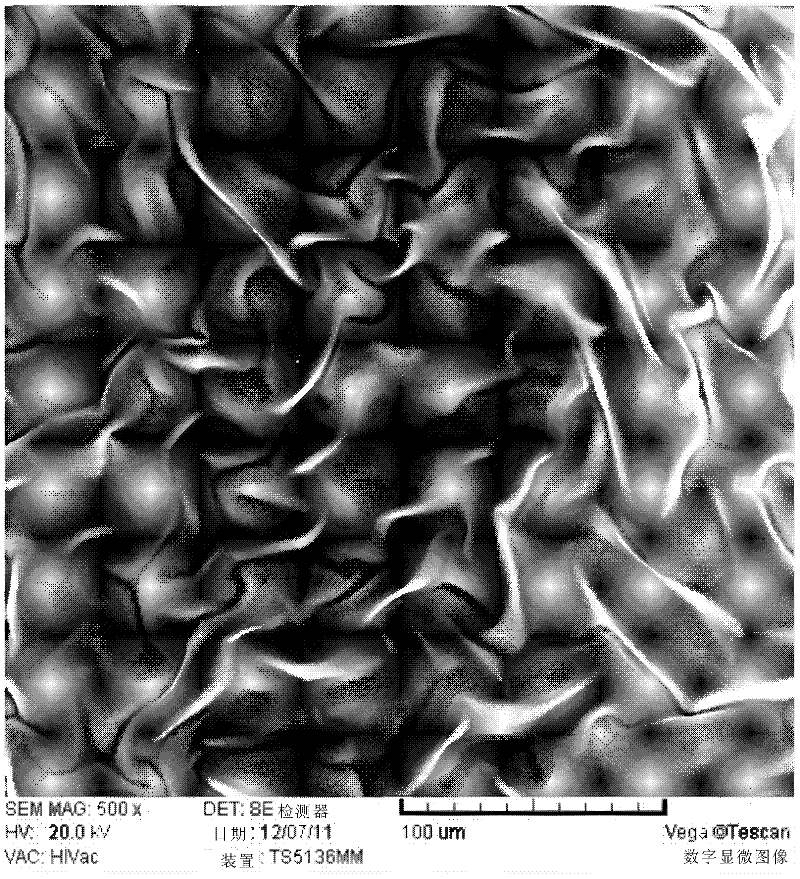

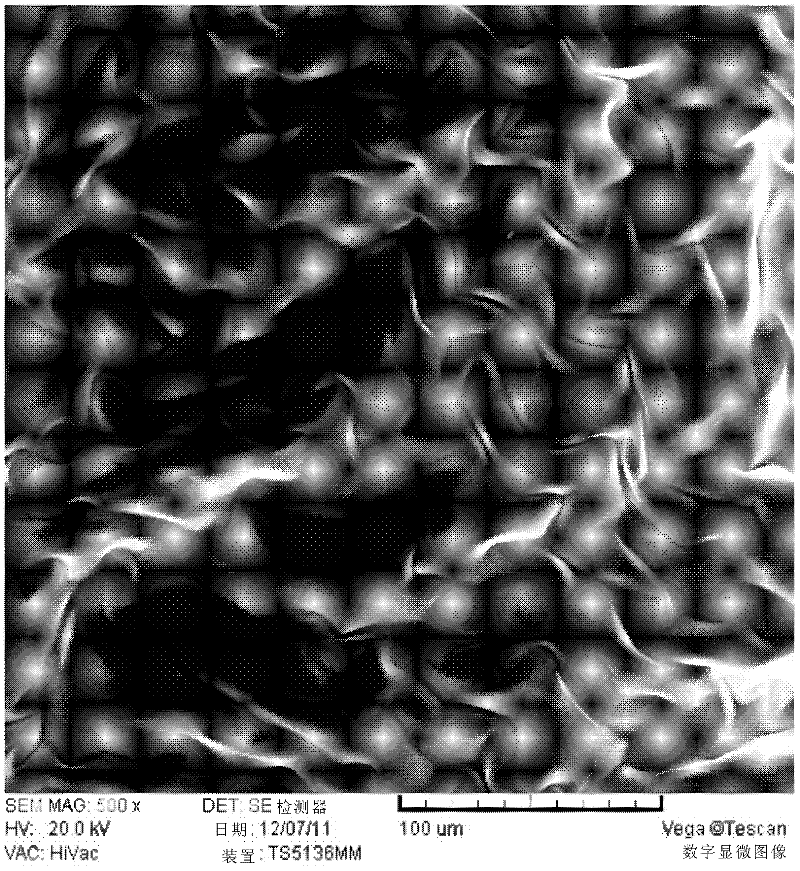

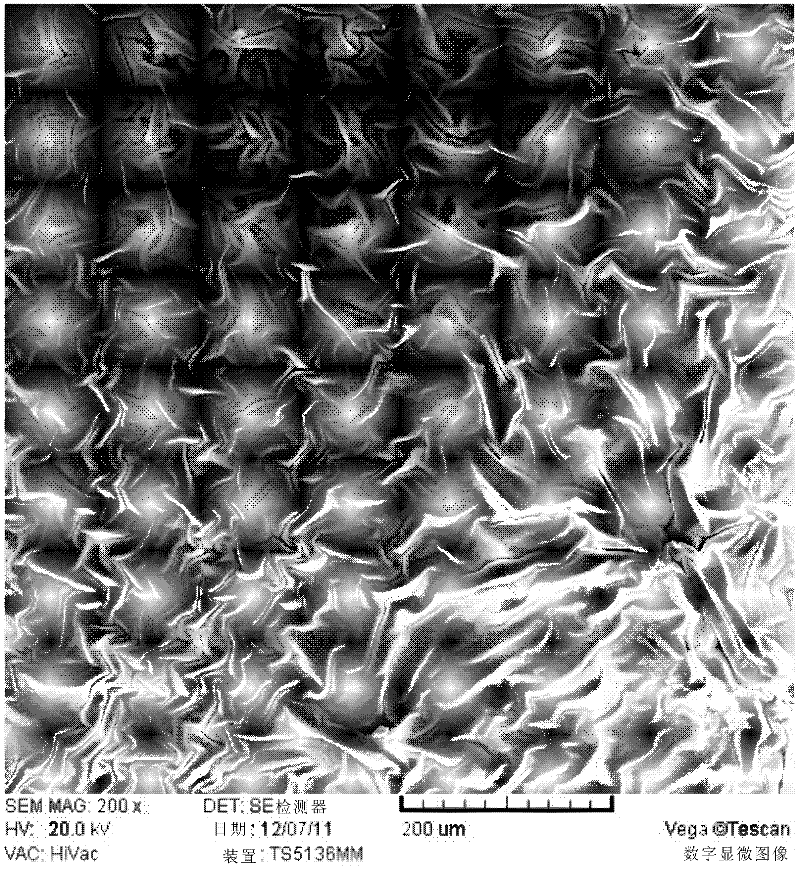

Image

Examples

Embodiment 1

[0075] The preparation of polyurea resin composition of the present invention

[0076] (1) Formula

[0077] 85.00 parts by weight of special acrylic resin of the present invention

[0078] 5.35 parts by weight of p-methoxybenzylamine

[0079] 1,6-dihexyl diisocyanate 3.65 parts by weight

[0080] Trimethylbenzene 6.00 parts by weight

[0081] (2) synthesis

[0082] 1) cooling the special acrylic resin of the present invention in a refrigerator for 24 hours, so that the temperature of the resin is lower than 5°C;

[0083] 2) Add the cooled acrylic resin into a reaction kettle protected by ice water, stir at a speed of 400 rpm, and add methoxybenzylamine at the same time to fully dissolve;

[0084] 3) Quickly add 1,6-dihexyl diisocyanate to it, and increase the stirring speed to 1200 rpm, keep the temperature at 10°C or lower, and continue stirring for 1 hour;

[0085] 4) Detect the reaction product, if the solid content is 60±1%, and the fineness is ≤10um, it is judged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com