Coke oven gas finely-purifying process for multiple combustion engines

A technology for coke oven gas and purification process, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, selection of absorbing solid gas purification, etc. Different requirements etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

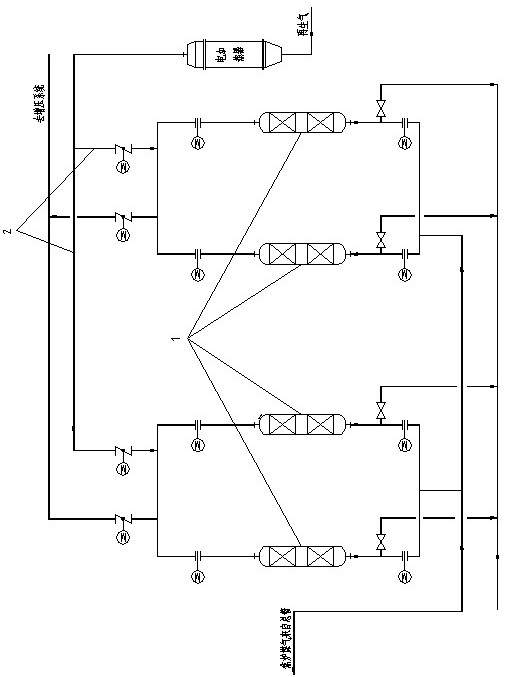

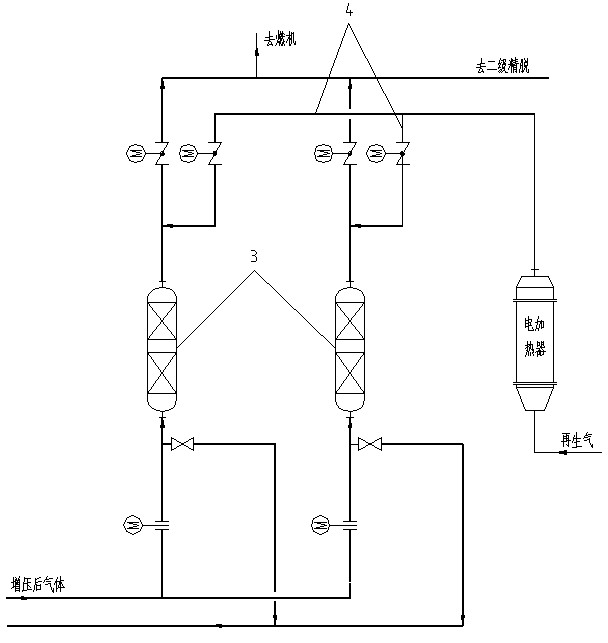

[0022] figure 1 It is a process flow chart of the coke oven gas fine purification process for various combustion engines of the present invention; figure 2 It is a schematic diagram of the roughing system flow; image 3 It is a schematic flow diagram of the first-stage essence extraction system; Figure 4 It is a schematic flow diagram of the two-stage essence extraction system.

[0023] As shown in the figure, this embodiment is used for the fine purification process of coke oven gas of various combustion engines, including the following steps:

[0024] a. Coke oven gas is roughed off by the coarse stripping system;

[0025] b. Use a pressurization system to pressurize the roughed coke oven gas;

[0026] c. Adopt at least two-stage fine-removal system to sequentially remove the supercharged coke oven gas, and the coke-oven gas after fine-removal in the upper-stage fine-removal system is divided into two parts, and part of the coke oven gas is sent into The matching gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com