High-wear-resistant steel for knitting needle and manufacturing method thereof

A technology with high wear resistance and manufacturing method, which is applied in the field of steel for knitting machinery, can solve the problems that it cannot be well adapted to high-strength knitting operations, and the fatigue resistance of knitting needles is not strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

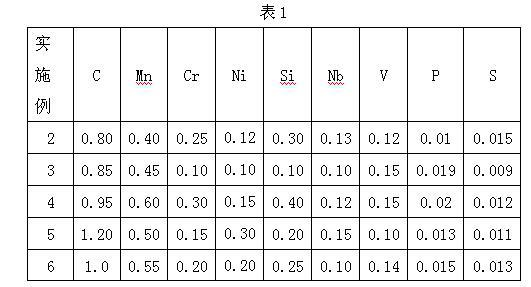

[0042] In this example, the composition and weight percentage of the cold work die steel are as follows:

[0043] C 1%, Si 0.2%, Mn 0.55%, Cr 0.2%, V 0.1%, Ni 0.1%, Nd 0.1%, P 0.02%, S 0.02%, and the balance is Fe and unavoidable impurities.

[0044] In the present embodiment, the process and steps of cold working die steel are as follows:

[0045] According to the ratio of the chemical components of the present invention, the steel ingot cast after smelting in the induction furnace is used as the consumable electrode and placed in the electroslag remelting device for electroslag remelting, and the liquid metal falls through the slag layer of the slag pool into the water-cooled crystallizer below, and then re-solidified into steel ingots; when the above-mentioned steel ingots are heated in the furnace, the furnace temperature is controlled at 500°C, heated at a heating rate of 60°C / h, and heated to a temperature of 1030°C, within this range After 3 hours of internal heat pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com