Discontinuous ultrasonic electroplating device and application thereof

An ultrasonic electroplating and ultrasonic technology, which is applied in the field of intermittent ultrasonic electroplating devices, can solve the problems of excessive thickness and brittleness of the ultrasonic electroplating hard film, and achieve the effects of convenient continuous production, improved wear resistance and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

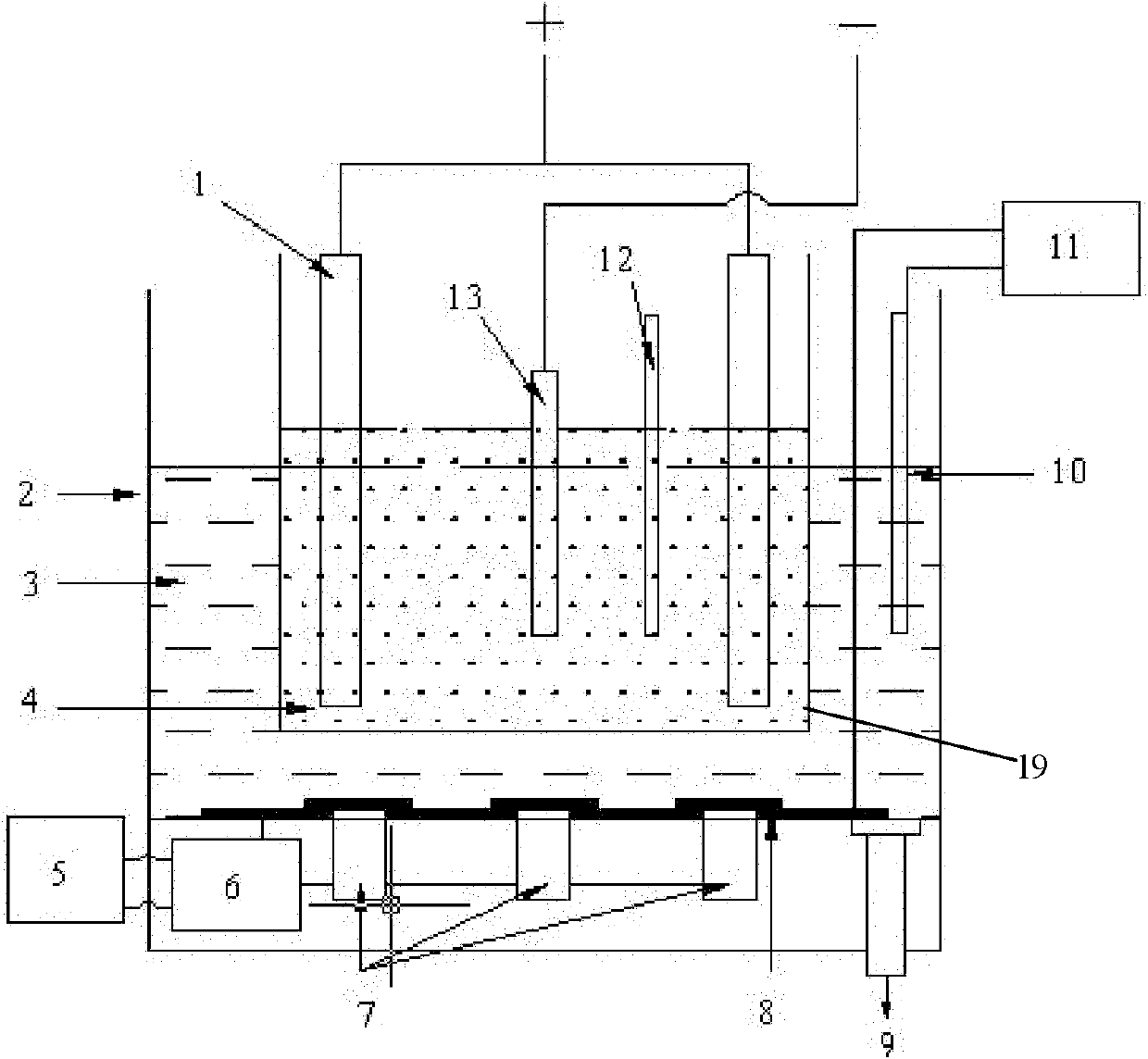

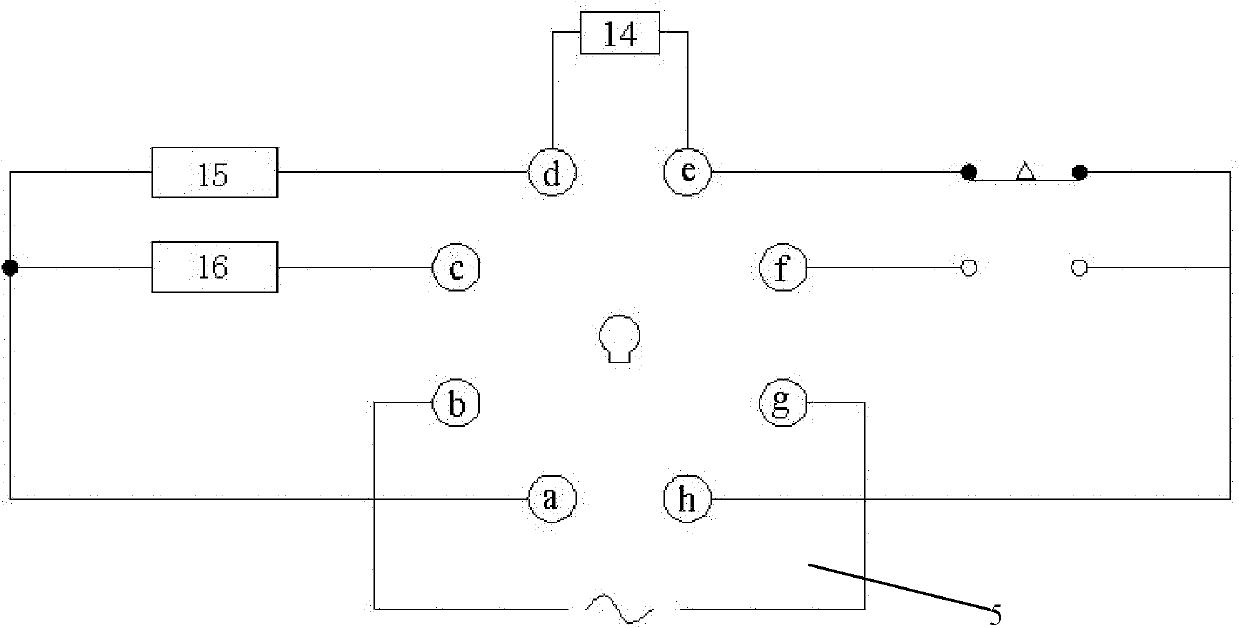

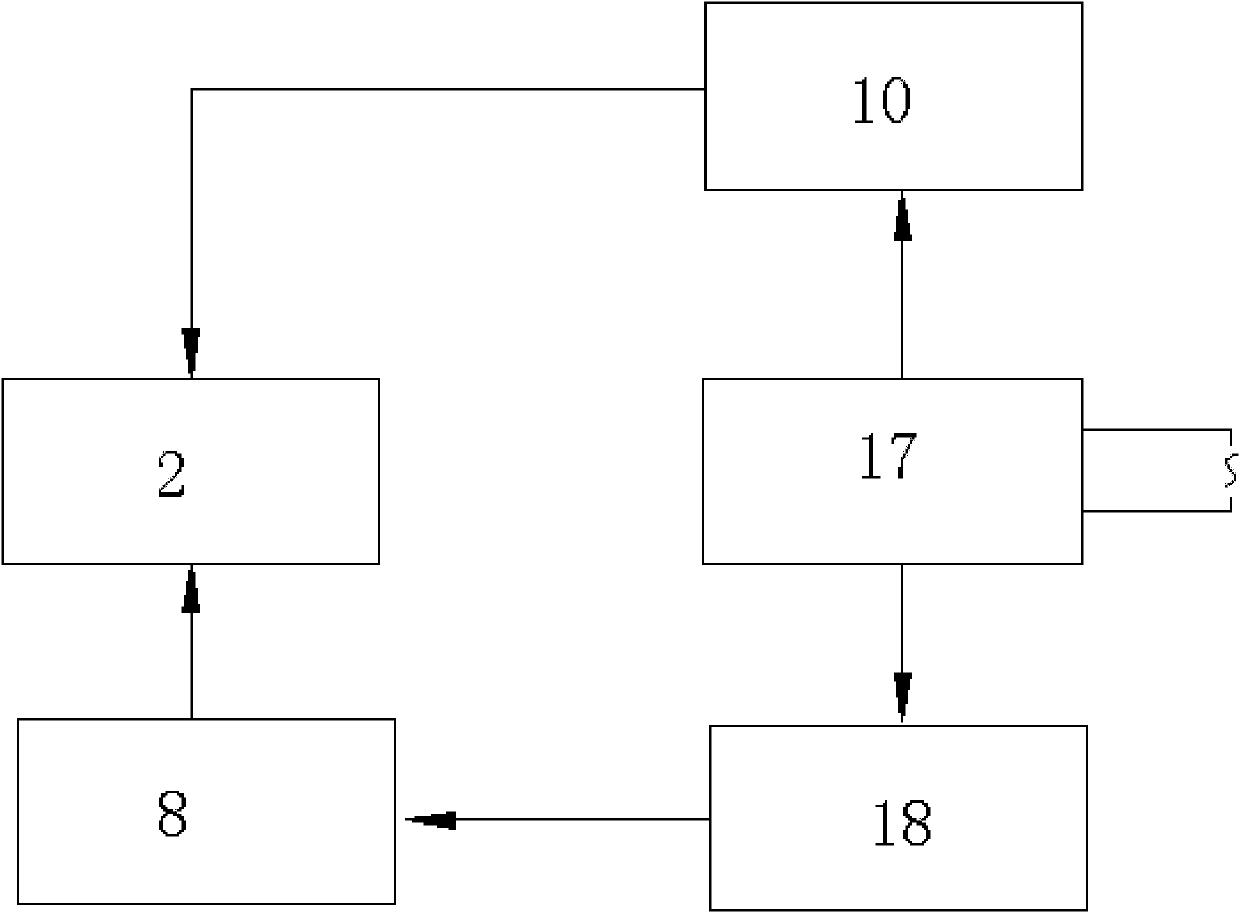

[0027] Such as figure 1 As shown, the intermittent ultrasonic electroplating device of the present invention mainly includes: electroplating electrode 1, ultrasonic water tank 2, water bath 3, plating solution 4, time relay 5, controller 6, ultrasonic generator 7, heater 8, water outlet 9, Thermocouple 10, water bath constant temperature control device 11, thermometer 12, electroplating sample 13, etc. The specific structure is as follows:

[0028] Water of a certain height is put into the ultrasonic water tank 2 to form a water bath 3. The plating solution 4 is put into the electroplating container 19, and the electroplating container 19 is placed in the ultrasonic water tank 2. The water surface of the ultrasonic water tank outside the electroplating container 19 is equal to or slightly lower than liquid level to prevent the container from floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com