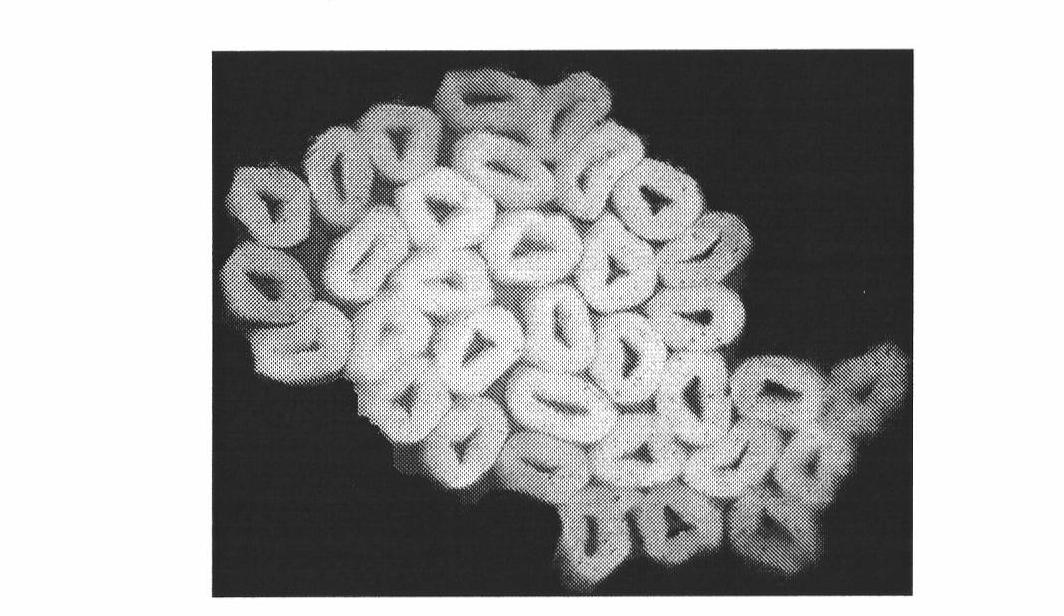

False twisted fibers and production method thereof

A manufacturing method and fiber technology, which are applied in the field of false twisted fibers and their manufacturing, can solve the problems of low expansion recovery rate, poor hand feeling, and insufficient fabric bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Pass the high-shrinkage polyester chips (polyester with more than 90 mole percent of ethylene terephthalate) with a moisture content of less than 100 ppm after vacuum drying through the screw extruder. ℃, make it into a molten state, flow into the metering pump, and press it into the component after accurate metering;

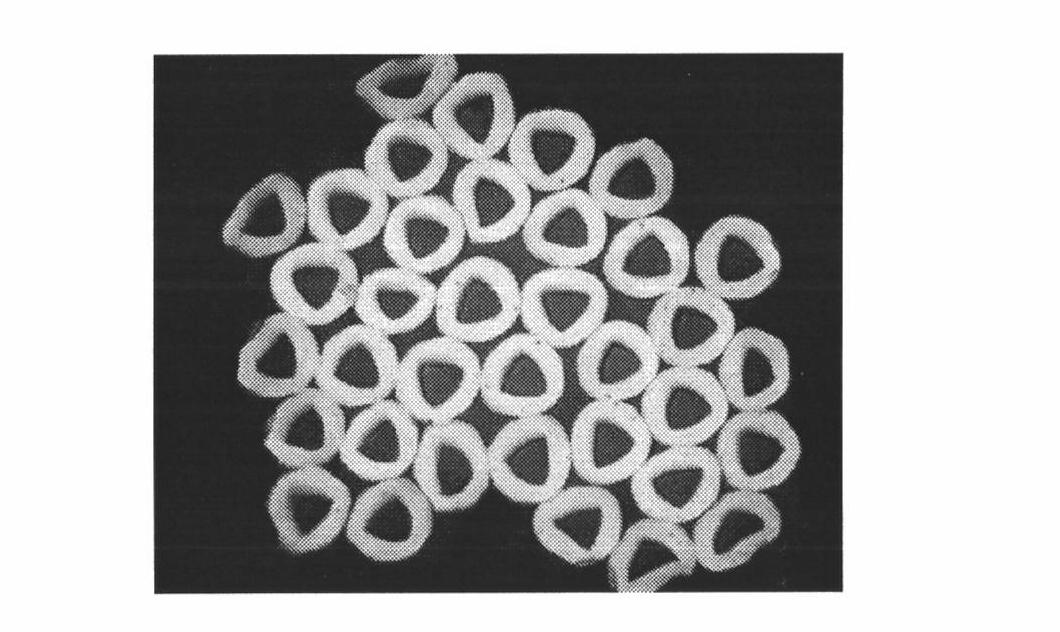

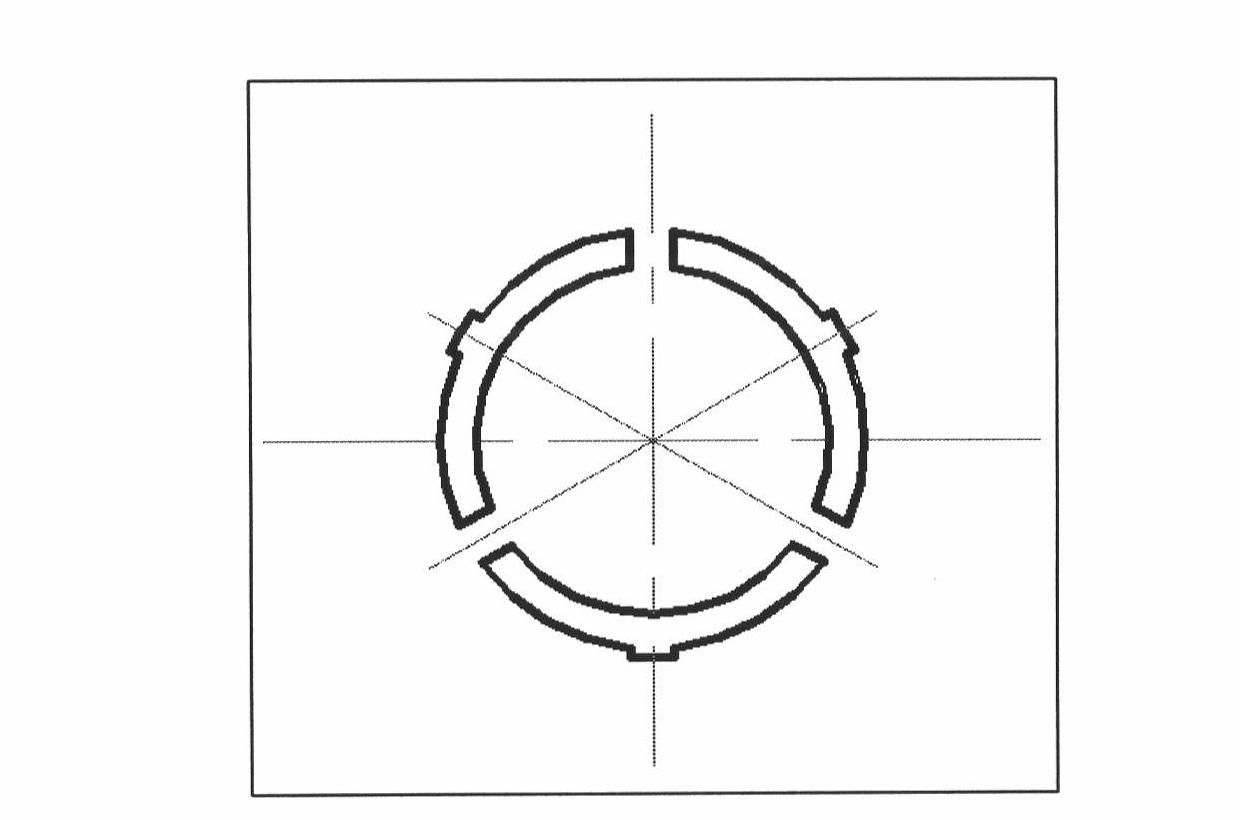

[0066] Use a triangular hollow spinneret for spinning, the hole depth of the spinneret is 135mm, and it is cooled by side blowing. °C, the temperature of the second hot roll is 130 °C, and the speed ratio between the two hot rolls: the first hot roll is 1.75. Control the fineness to 95dtex / 36F to obtain hollow fully oriented yarn FOY;

[0067] Low-temperature false-twist processing is carried out on the wound hollow drawn yarn FOY. The temperature of the first hot box of the false twister is set at 60°C, the temperature of the second hot box is at room temperature, the magnification is 1.05, and the coiling speed is 450m / min, so that the denier is 84dte...

Embodiment 2

[0069] Pass the high-shrinkage polyester chips (polyester with more than 90 mole percent of ethylene terephthalate) with a moisture content of less than 100 ppm after vacuum drying through the screw extruder. ℃, make it into a molten state, flow into the metering pump, and press it into the component after accurate metering;

[0070] Use a triangular hollow spinneret for spinning, the hole depth of the spinneret is 135mm, and it is cooled by side blowing. °C, the temperature of the second hot roll is 130 °C, and the speed ratio between the two hot rolls: the first hot roll is 1.75. Control the fineness to 95dtex / 36F to obtain hollow fully oriented yarn FOY;

[0071] Low-temperature false-twist processing is carried out on the wound hollow stretched yarn FOY. The temperature of the first hot box of the false twister is set at 80°C, the temperature of the second hot box is at room temperature, the magnification is 1.05, and the coiling speed is 450m / min, so that the denier is 8...

Embodiment 3

[0073] Pass the high-shrinkage polyester chips (polyester with more than 90 mole percent of ethylene terephthalate) with a moisture content of less than 100 ppm after vacuum drying through the screw extruder. ℃, make it into a molten state, flow into the metering pump, and press it into the component after accurate metering;

[0074] Use a triangular hollow spinneret for spinning, the hole depth of the spinneret is 135mm, and it is cooled by side blowing. °C, the temperature of the second hot roll is 130 °C, and the speed ratio between the two hot rolls: the first hot roll is 1.75. Control the fineness to 95dtex / 36F to obtain hollow fully oriented yarn FOY;

[0075] Low-temperature false-twisting processing is carried out on the wound hollow drawn yarn FOY. The temperature of the first hot box of the false twister is set at 100°C, the temperature of the second hot box is at room temperature, the magnification is 1.05, and the coiling speed is 450m / min, so that the denier is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com