Moisture and sweat absorption double-side peached-finish towel and manufacturing process thereof

A technology of moisture absorption and perspiration, double-sided grinding, applied in textiles and papermaking, fabrics, textiles, etc., can solve the problems of not being soft and fit, airtight, unable to meet the quality requirements, etc., to ensure the function of keeping warm, improve air permeability, Reduce manual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

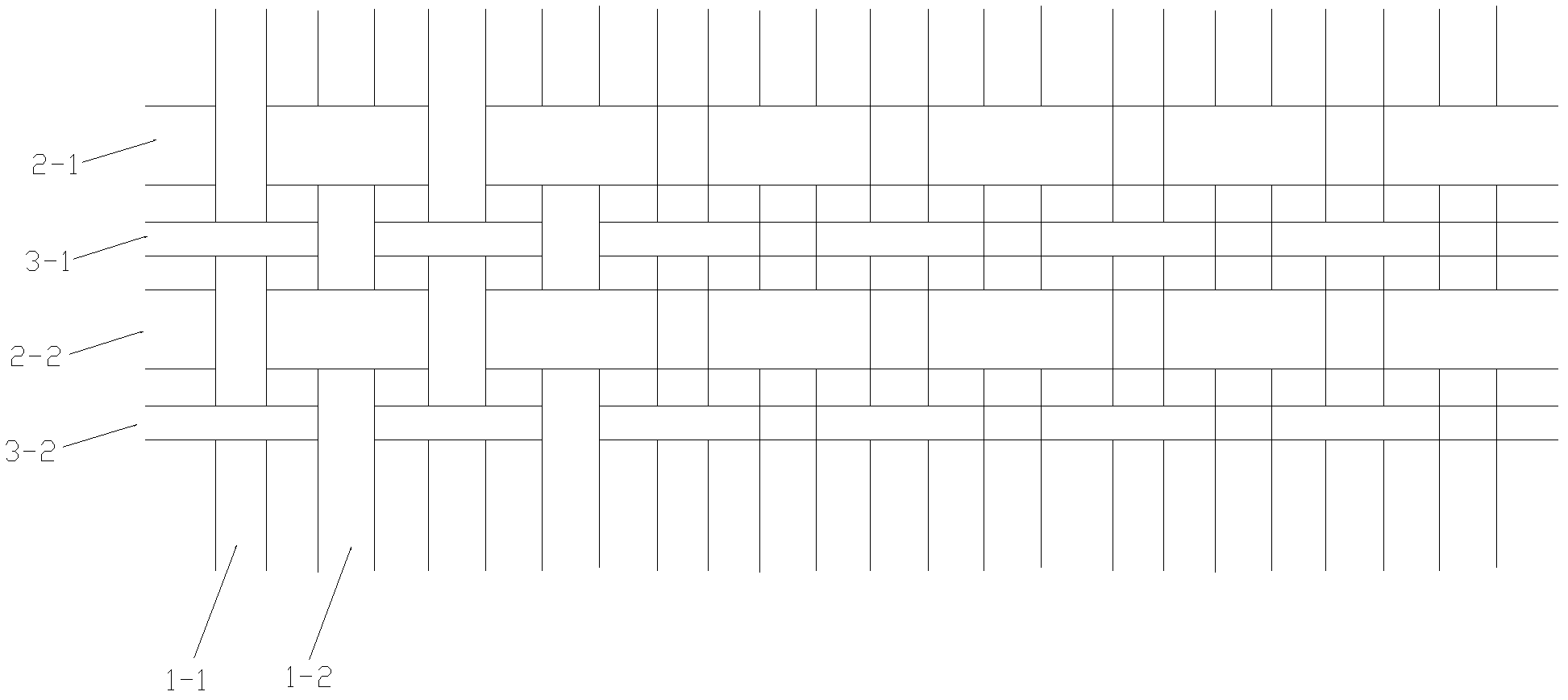

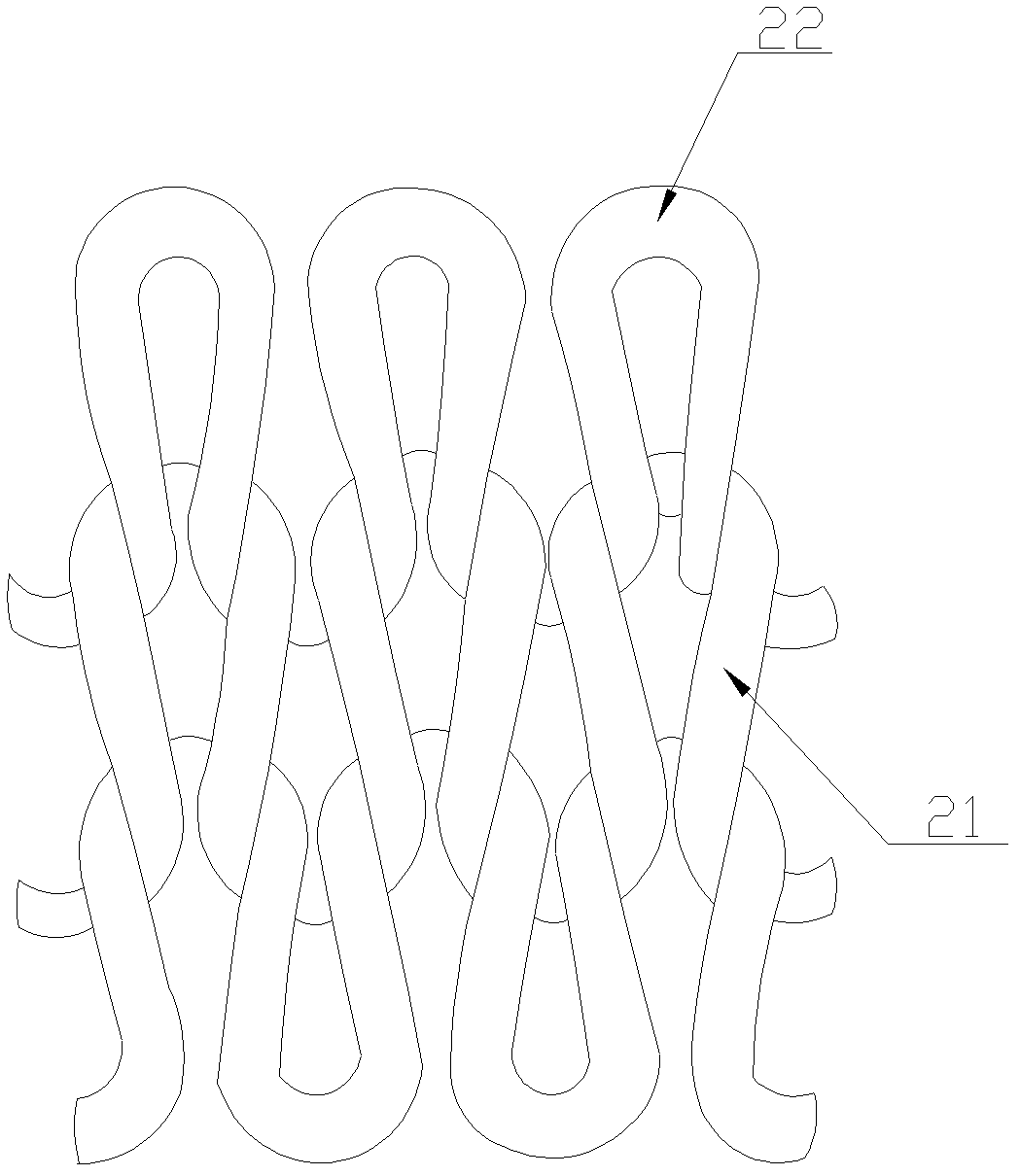

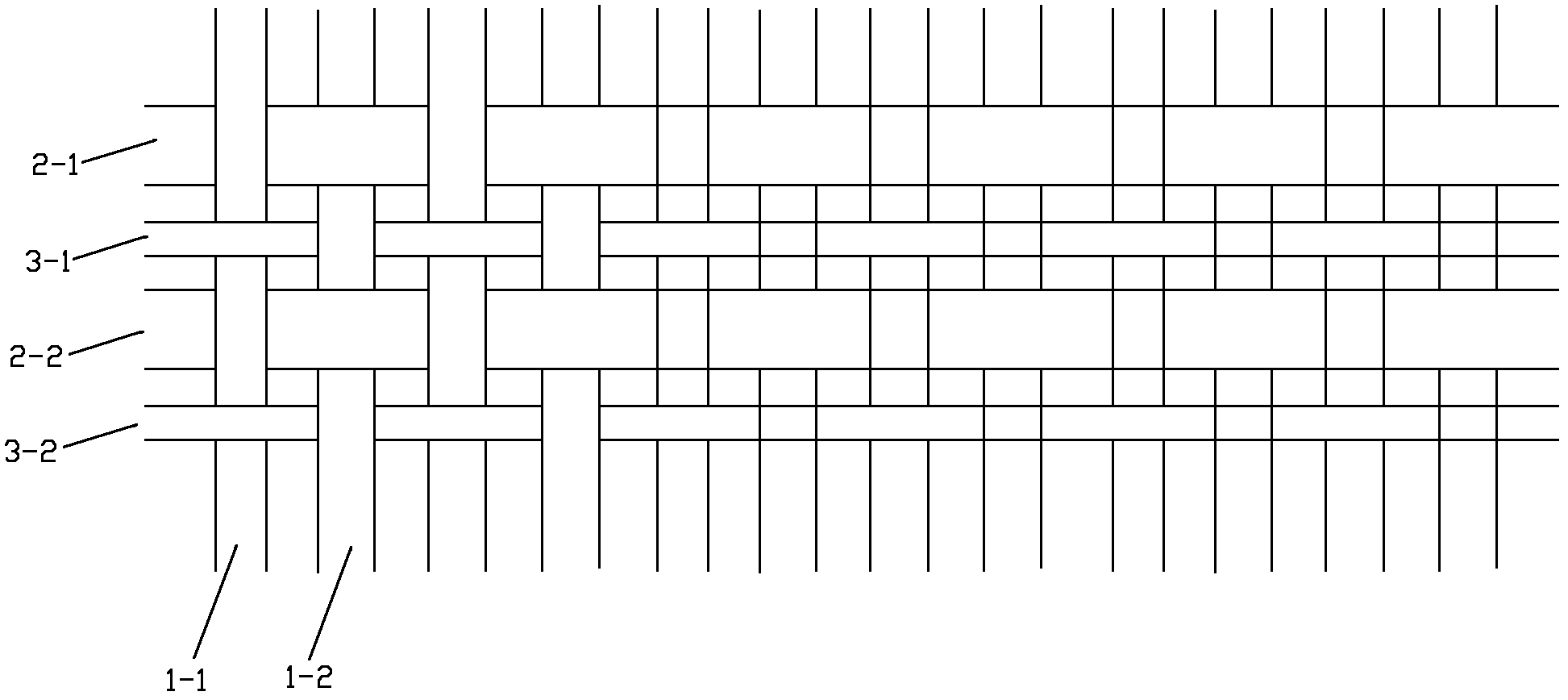

[0023] Such as Figure 1~2 Moisture-wicking double-sided grinding towel shown, comprising microfiber connecting yarn 1, upper layer yarn 2 and lower layer background yarn 3, has a double-layer structure, and microfiber connecting yarn 1 is interwoven with upper layer yarn 2 and lower layer background yarn 3 into several structural units, the upper yarn 2 is weft-knitted from the inner yarn 21 and the outer yarn 22, and the bottom yarn 3 of the lower layer is Coolmax fiber.

[0024] Further, the upper veil 2 has a plain weave structure. Because the plain weave has many interweaving points, the warp and weft threads are most tightly hugged, so the texture of the upper layer yarn 2 is the firmest and the appearance is the most flat.

[0025] Further, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com