Building method for mound-free suspension bridge

A construction method and suspension technology, applied in bridge construction, bridges, bridge parts, etc., can solve problems such as difficulties, delays in time, delays in disaster relief opportunities, etc., to achieve rapid and convenient construction, ensure stability and safety, and simplify construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

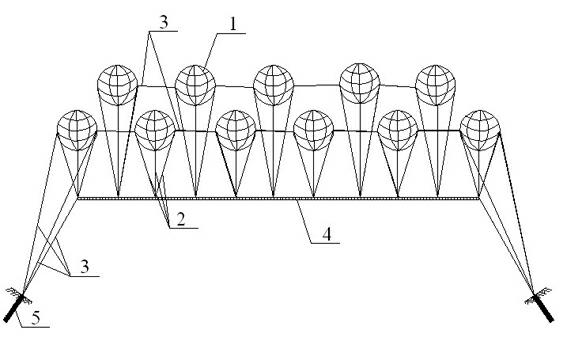

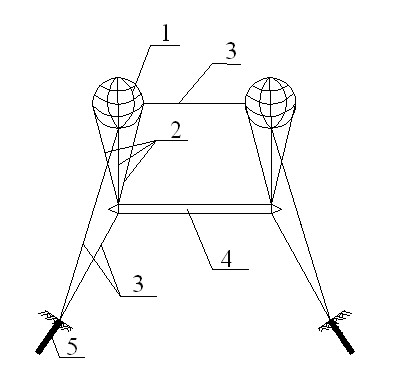

[0025] Example 1: see figure 1 , figure 2 , the construction method of suspension bridge without piers, comprising the following steps:

[0026] (1) Prefabrication of large section components of beams and slabs of the carriageway: Prefabricate beams and slabs in the factory according to the requirements of standing machinery and equipment (flat steel box structure can be used, and military beams of standing Bailey frame can also be used). According to the requirements of transportation and assembly during prefabrication, large standard parts are assembled as much as possible, and only simple assembly is required on the erection site.

[0027] The prefabricated beam slab is a flat steel box girder with a section of 3m (with various reinforcements inside), or a truss beam similar to a Bailey beam (every 3m section), which is assembled from 3-4 sections into a large beam section. The dead load concentration is about 45 kN / m.

[0028] (2) Prefabrication of umbrella-shaped v...

Embodiment 2

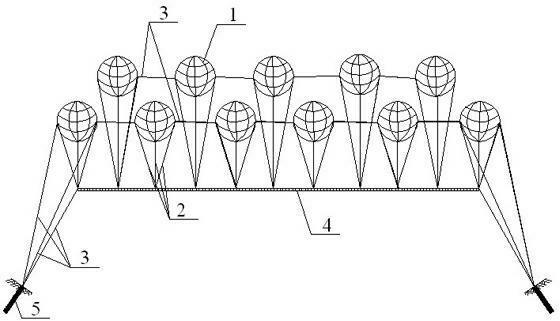

[0049] Example 2: It is basically the same as Embodiment 1, except that the span of the suspended bridge without piers is 30m, the width is 6m, and the gas filled in the balloon is changed to helium. The following specific analysis.

[0050] If the filling gas is changed to helium (the density of helium is 0.1786g / L at 0°C and 1 standard atmospheric pressure), the span of the bridge is 30m, and the width is still 6m. The sum of the dead load and live load concentration of the driving girder is still: 10.5 + 43.8 = 54.3 kN / m. The vertical cables of the bridge are finished cables (prefabricated parallel steel wire bundles), and the diameter of the finished vertical cables is 5-10cm. Considering the Clips and other loads that are not included, if the self-weight of the cable is conservatively taken as 5 kN / m, then the dead load and live load concentration of the entire structure is: 54.3 + 5 = 59.3 kN / m, and 60 kN / m is taken for safety considerations . Then, the total weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com