Inlet and outlet sealing structure of tobacco dryer

A sealing structure and technology of drying machine, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of increased material consumption, easy damage of wool felt, and poor sealing of the cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

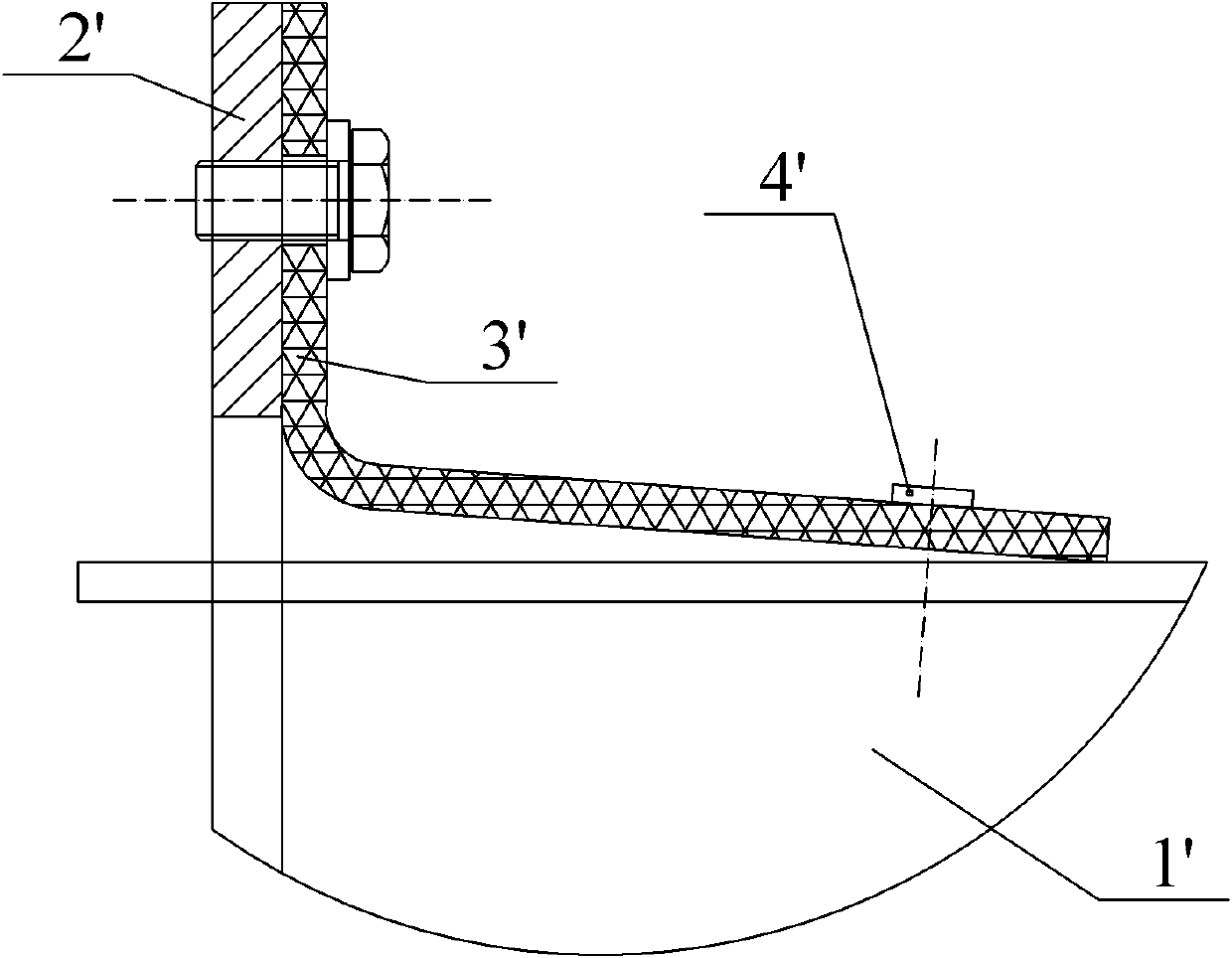

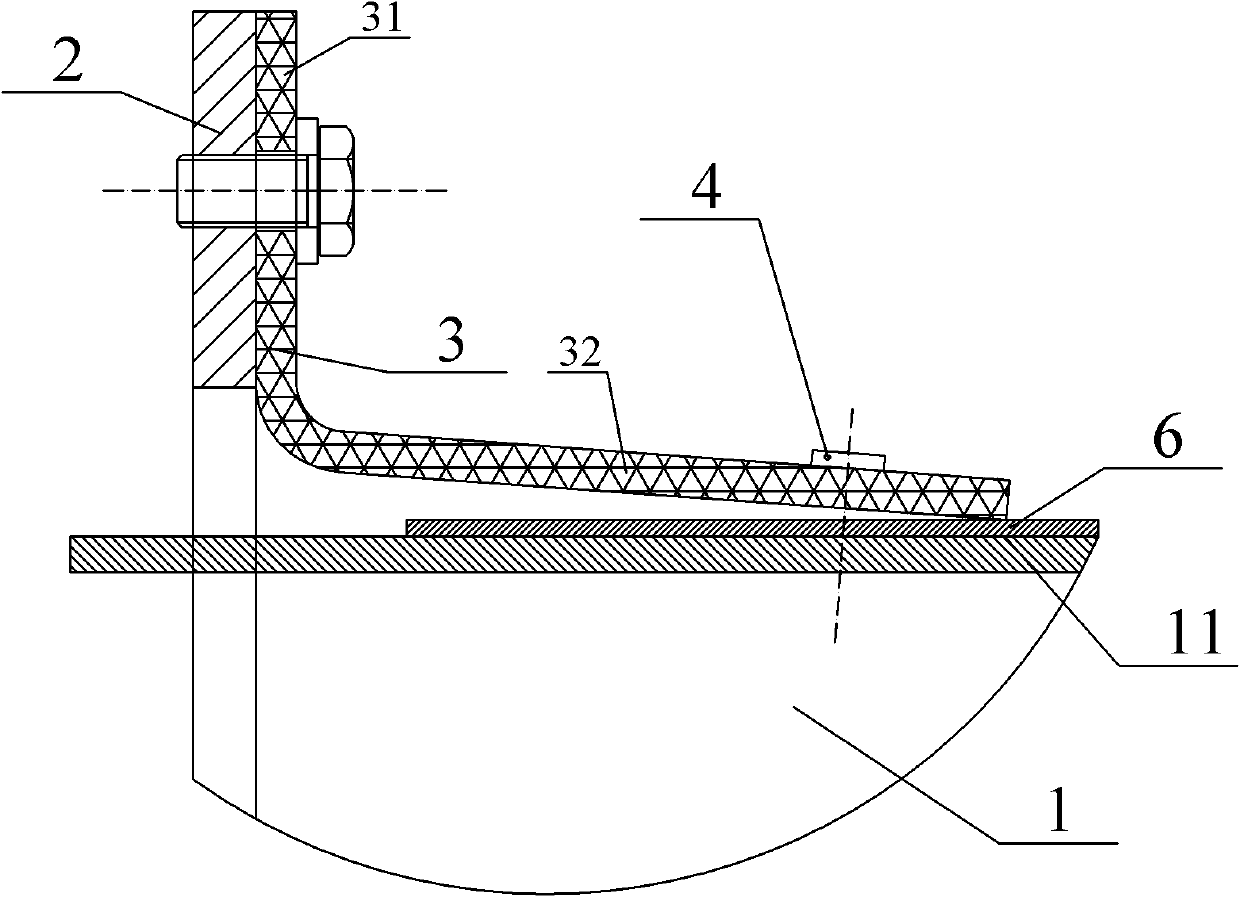

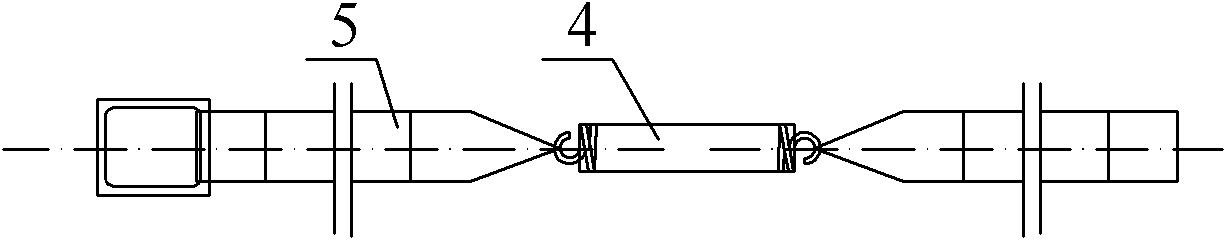

[0017] See figure 2 , is a schematic diagram of the inlet and outlet sealing structure of the silk drying machine involved in the present invention. The sealing structure includes a cylinder 1 and a seal, the surface of the cylinder 1 is the cylinder sealing surface 11, the seal is curved and includes first and second subsections 31, 32, and the first subsection 31 is compacted Fitted on the cylinder sealing surface 11, the second subsection 32 is fixedly connected with the front and rear chambers 2 of the silk dryer. on the seal and is tensioned by tension spring 4, see image 3 , thereby realizing the fixing of the second subsection 32 . The sealing member is a silica gel plate 3 . The main characteristics of the silica gel plate are non-toxic, environmentally friendly, high and low temperature resistance (-80°C-300°C), aging resistance, strong deformation resistance, strong resilience, compression resistance and permanent deformation, etc. At present, the working envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com