Air-cooling water chiller

A technology of air-cooled chillers and air-cooled condensers, which is applied in the direction of refrigerators, refrigeration components, compressors, etc., and can solve problems such as difficult compressor oil return, system vibration, troublesome maintenance and adjustment, etc., to achieve normal operation protection, Avoid system shock and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

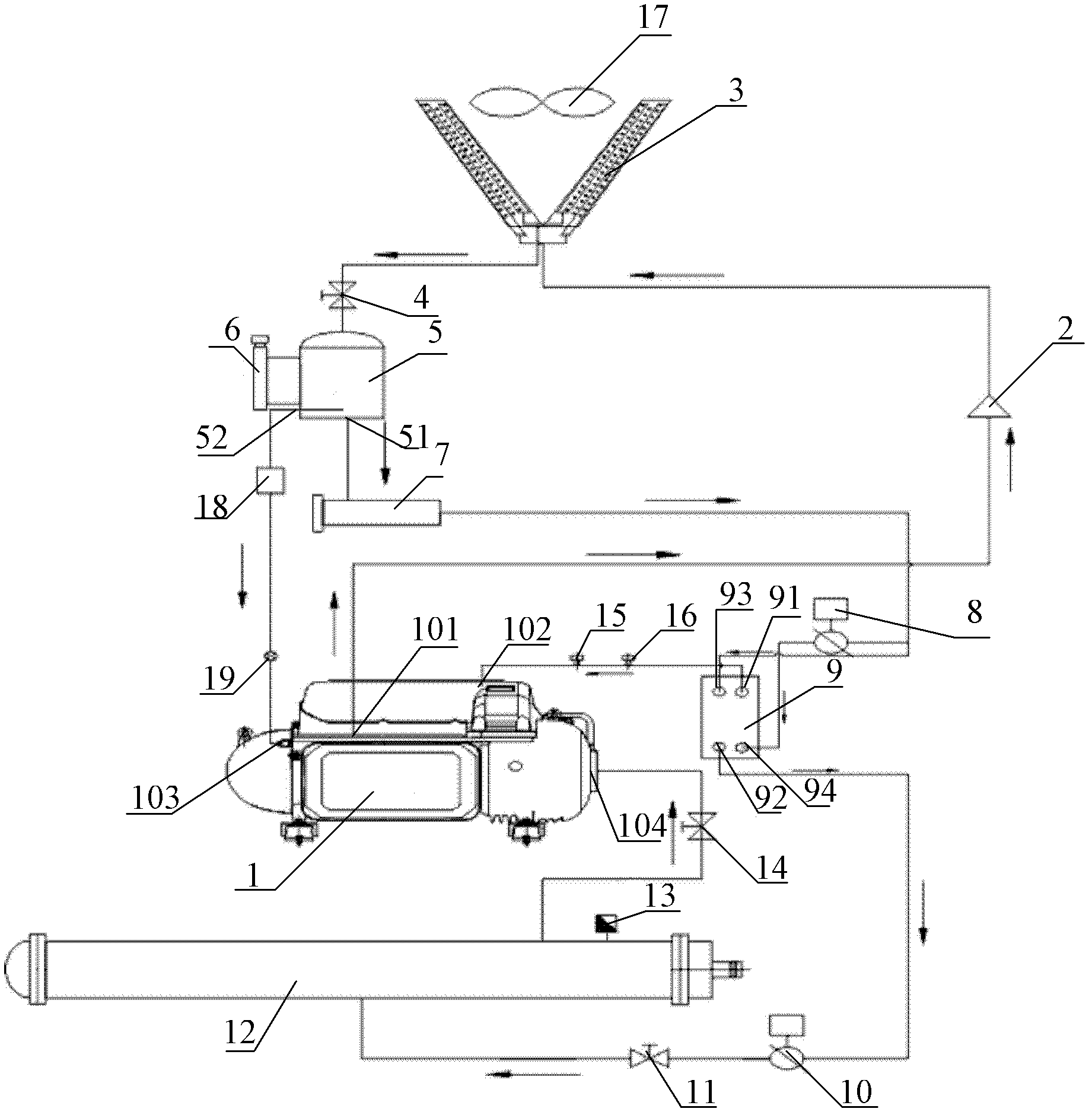

[0031] like figure 1 As shown, an air-cooled chiller according to the present invention includes a compressor 1, an air-cooled condenser 3, a liquid storage tank 5, a flooded evaporator 12, an expansion valve 10 and a unit control system. A liquid level gauge 6 is installed on the 5, and the liquid level signal of the liquid level gauge 6 is input to the unit control system and linked with the expansion valve 10 to control the refrigerant circulation amount.

[0032]The compressor 1 includes an exhaust port 101, an economizer port 102, a liquid jet port 103, and a suction port 104. The exhaust port 101 of the compressor 1 is connected to the inlet of the check valve 2, and the outlet of the check valve 2 is connected to the air cooling The inlet of the condenser 3 is connected, and the outlet of the air-cooled condenser 3 is connected with the inlet of the first ball valve 4. Here, a fan 17 for cooling is provided on one side of the air-cooled condenser 3, and the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com