Novel pre-crystallizer

A pre-crystallizer, a new type of technology, applied in the direction of furnace type, filament forming treatment, lighting and heating equipment, etc., can solve the problems of fast and excessive heating speed, affecting the quality of pre-crystallization slices, etc., and achieve the effect of sufficient crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

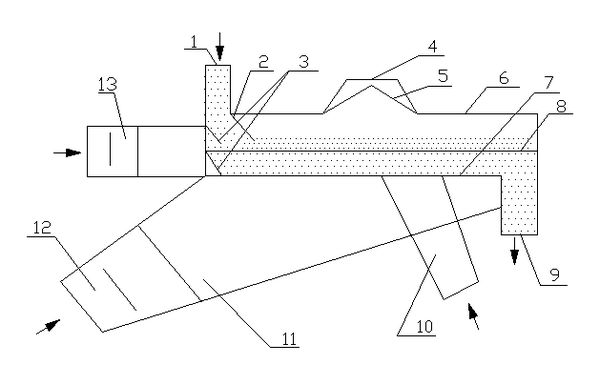

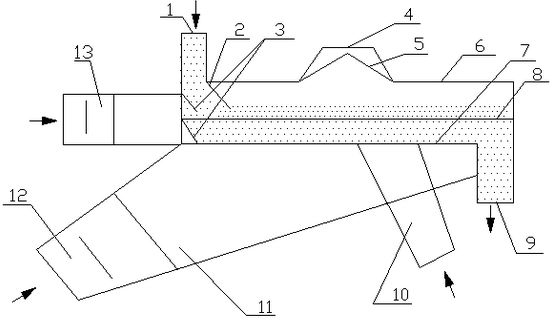

[0013] Such as figure 1 A new type of pre-crystallizer shown is a cylindrical container made of stainless steel as a whole, and the right side is made of transparent high-temperature-resistant tempered glass. A baffle plate 2 and two adjustable baffle plates 3 are arranged, and the two adjustable baffle plates 3 are fixed on the left side of the device wall 6 in parallel, and a material leakage plate 8 is arranged between the two adjustable baffle plates 3, and the material leakage plate An orifice 7 is arranged below 8, and the left side of the two adjustable baffles 3 is connected to a circular hot air passage, and the other side of the hot air passage is connected to a hot air blower 13, and a gas outlet 4 is arranged in the middle of the upper part of the pre-crystallizer wall 6, and the gas outlet 4 A conical cap 5 is set inside, a slice outlet 9 is set at the lower right of the pre-crystallizer, a circular air duct 11 is set on the left side under the orifice plate 7, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com