Rotary-vibration electromagnetic heating drier

A heating drying and electromagnetic heating device technology, applied in dryers, heating devices, drying solid materials, etc., can solve the problems of uneven drying inside and outside, long heating time, slow heating speed, etc., and achieve uniform drying and heating speed. Fast and easy discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

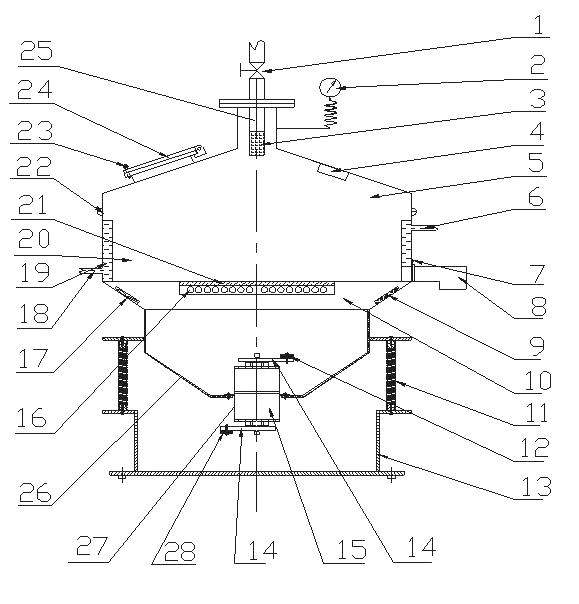

[0017] The specific embodiment: below in conjunction with accompanying drawing, the best embodiment of the present invention is described in detail:

Embodiment

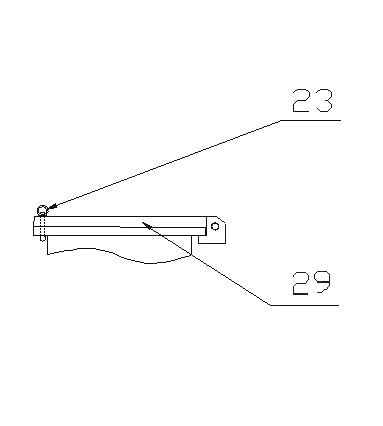

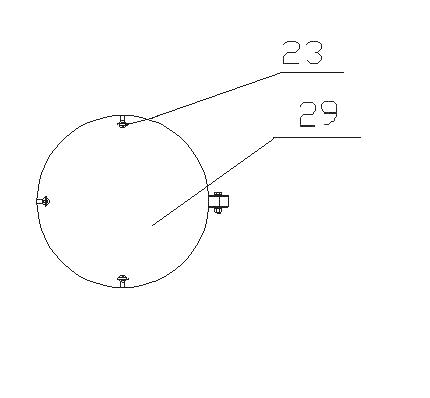

[0018] Embodiment: a kind of rotary vibration electromagnetic heating dryer (see Figure 1-Figure 4 ), which includes the equipment base 13, the equipment base 13 is connected to the equipment main body 26 through the spring bracket 11, the spring bracket 11 supports the equipment main body 26, and a rotary vibration device 27 is provided at the bottom of the equipment main body 26, and the rotary vibration device 27 is composed of a vibration motor 15, The weight 14, the upper weight plate 12 and the lower weight plate 28 are composed. The main body of the rotary vibration device 27 is a vibration motor 15. The upper and lower parts of the vibration motor 15 are respectively provided with a weight 14, and the upper weight plate 12 is installed on the upper weight 14. , under the bottom heavy hammer 14, the lower weighting sheet 28 is installed, and the weight of the upper weighting sheet 12 and the lower weighting sheet 28 is different. The upper end of equipment main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com