Multi-medium-flow high-pressure plate type heat exchanger

A high-pressure plate and multi-media technology, applied in the direction of indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problem of heat waste in comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

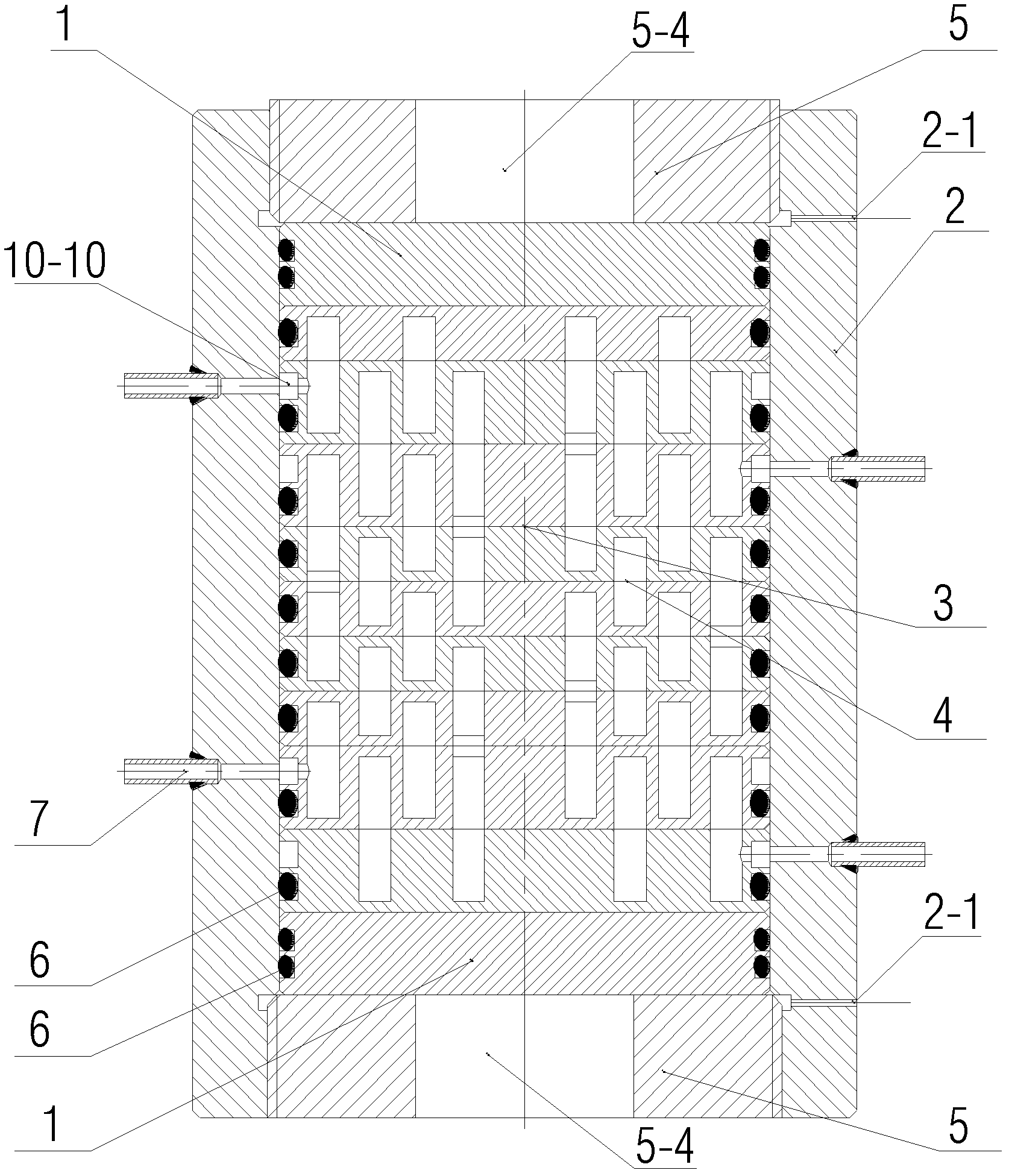

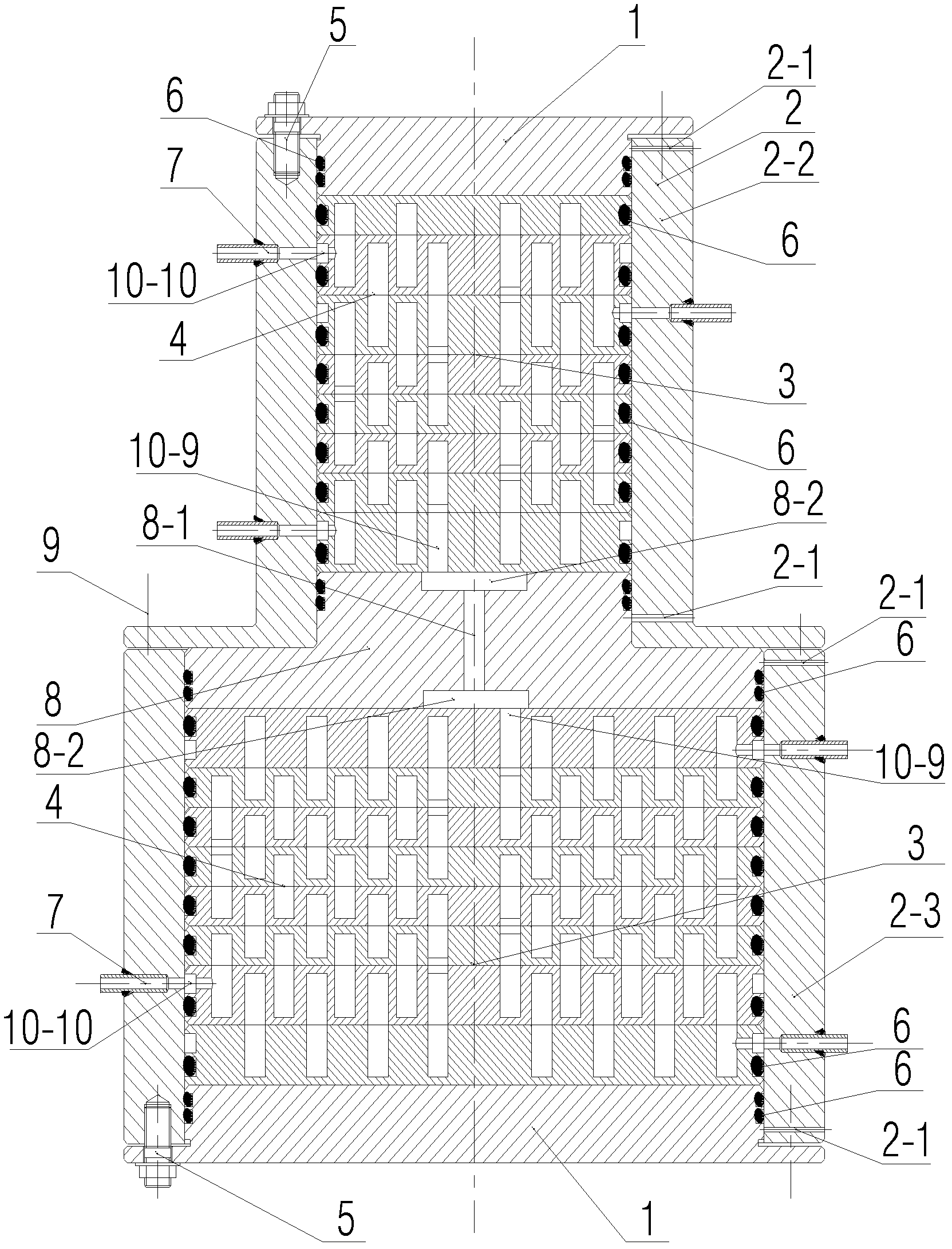

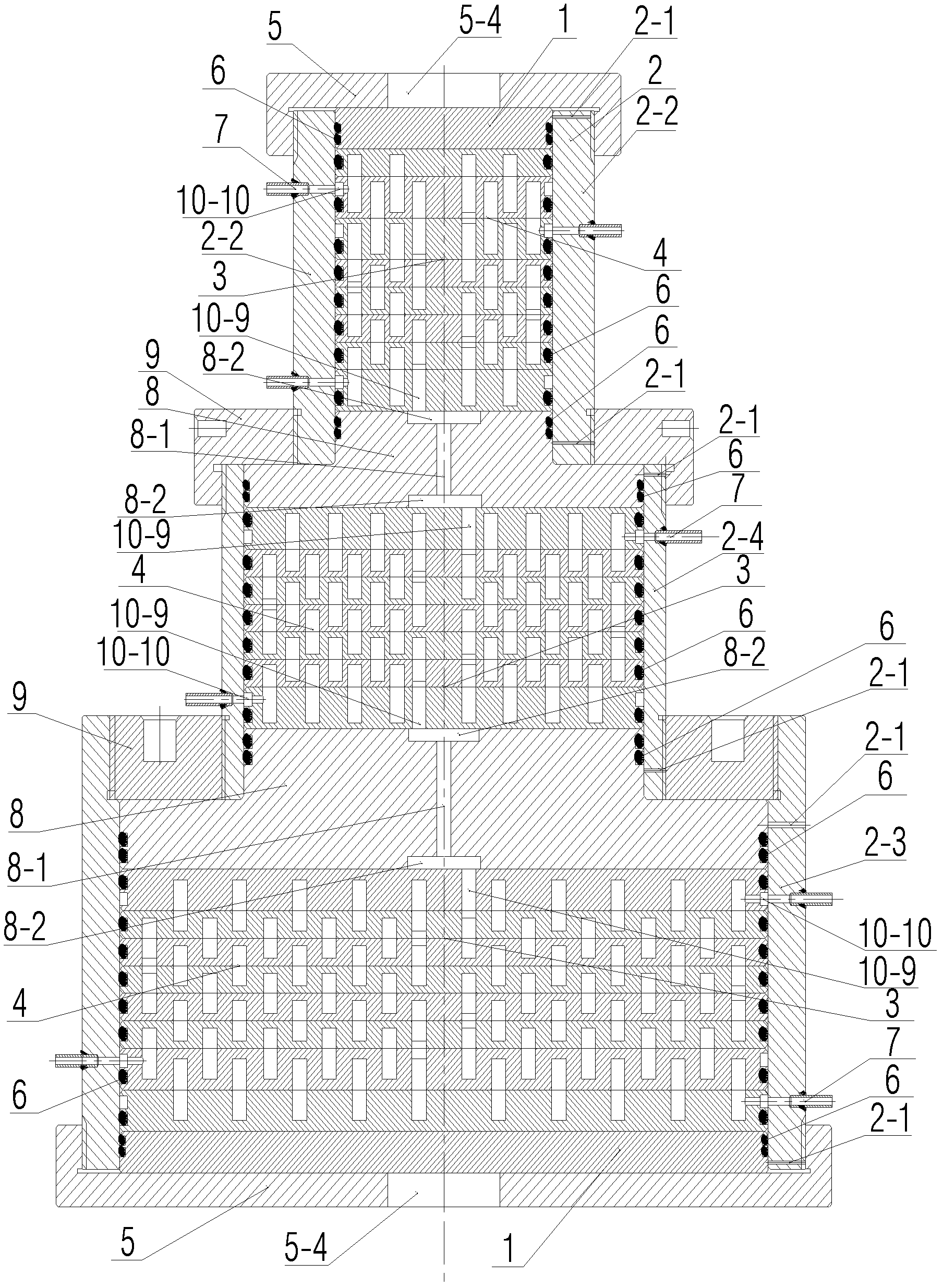

[0102] 1. Embodiment one: as figure 1 The basic components shown are selected to assemble a single cylinder multi-media flow high-pressure plate heat exchanger.

[0103] According to the working pressure, flow rate, flow mode and heat transfer volume of the heat transfer medium, the diameter of the cylinder 2 is determined, and the required total heat transfer area and the cross section of the spiral flow channel for the medium entering and leaving the heat transfer plate 10 and the pure heat transfer plate 11 are calculated. Area; calculate the heat transfer area of the medium entering and exiting the heat exchange plate group, and subtract the heat transfer area of the medium entering and exiting the heat exchange plate group from the total heat exchange area to obtain the required pure heat exchange plate heat transfer area, and then the required pure heat exchange plate The value obtained by dividing the heat exchange area by the heat exchange area of a single pure h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com