Automatic testing device and testing method for laser damage threshold value

An automatic testing device and laser damage threshold technology, which is applied in the direction of testing optical performance, can solve the problems of no multi-purpose general-purpose commercial laser threshold testing device, large uncertainty of test data, uneven indicators, etc., to achieve The effect of high degree of automation, guaranteed reliability and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below through specific embodiments in conjunction with the drawings.

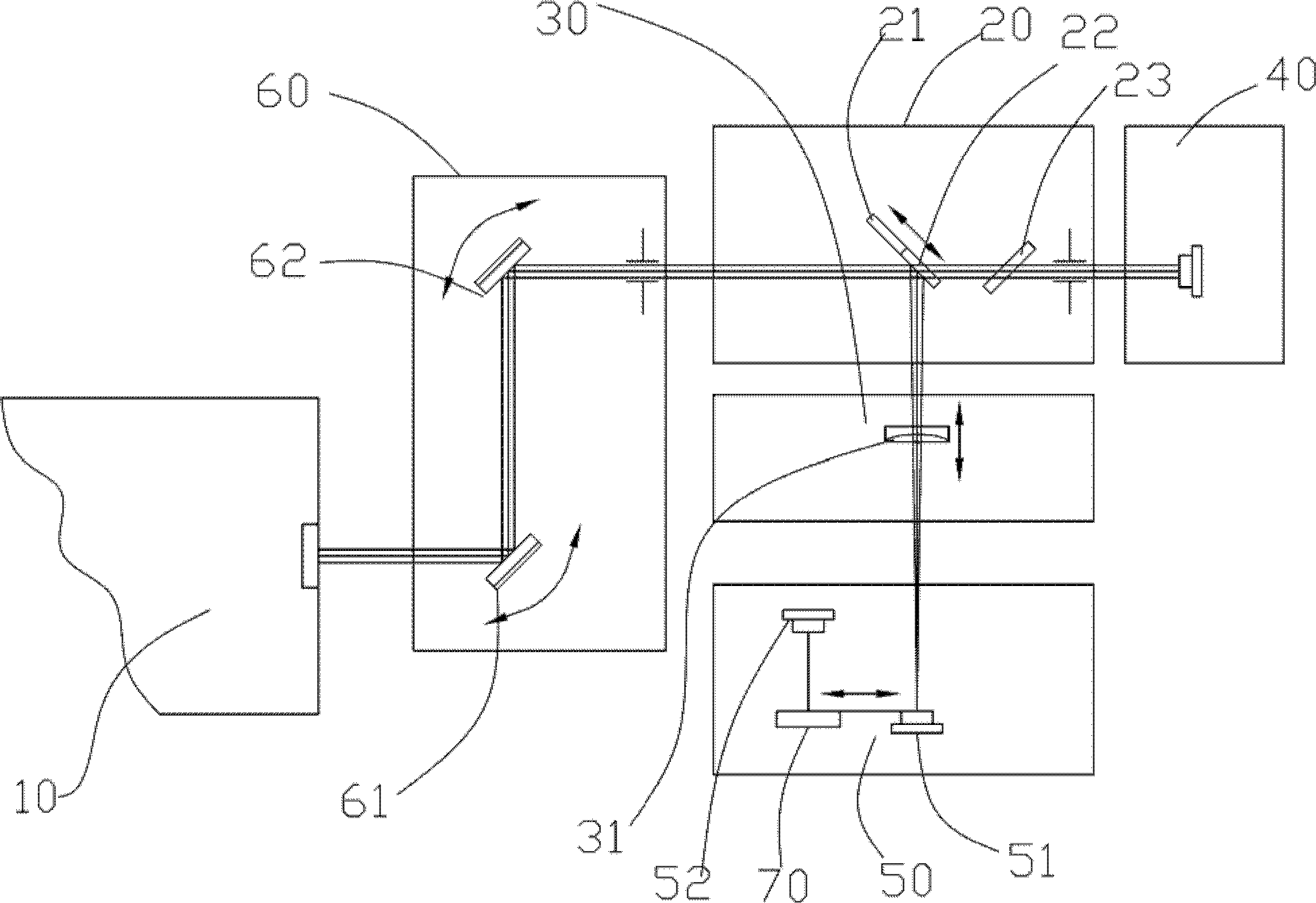

[0036] Please refer to figure 1 As shown, an automatic laser damage threshold test device 100 includes: a laser 10, a light splitting attenuation system 20, a focusing system 30, an energy collection system 40, a sample stage, a beam collection system 50, and a processing system (not shown), wherein The light splitting attenuation system 20 and the energy collection system 40 are located on the first main optical axis of the laser beam emitted by the laser 10, and the focusing system 30 and the beam collection system 50 are located on the first main optical axis perpendicular to the first main optical axis. On the two main optical axes, the light splitting attenuation system 20 includes a high reflection mirror 21, a high transmission mirror 22, a linkage mechanism, a figure-eight compensation high transmission mirror 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com