Method for determining high-temperature evaporation loss of lubricating oil

A high-temperature evaporation and evaporation loss technology, applied in the field of measurement, can solve the problems of easy overheating of the aluminum bath temperature, high evaporation loss test results, and difficult control of the air outlet temperature, and achieve the effect of meeting the design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Determination of the evaporation loss of m-terphenyl at 205°C.

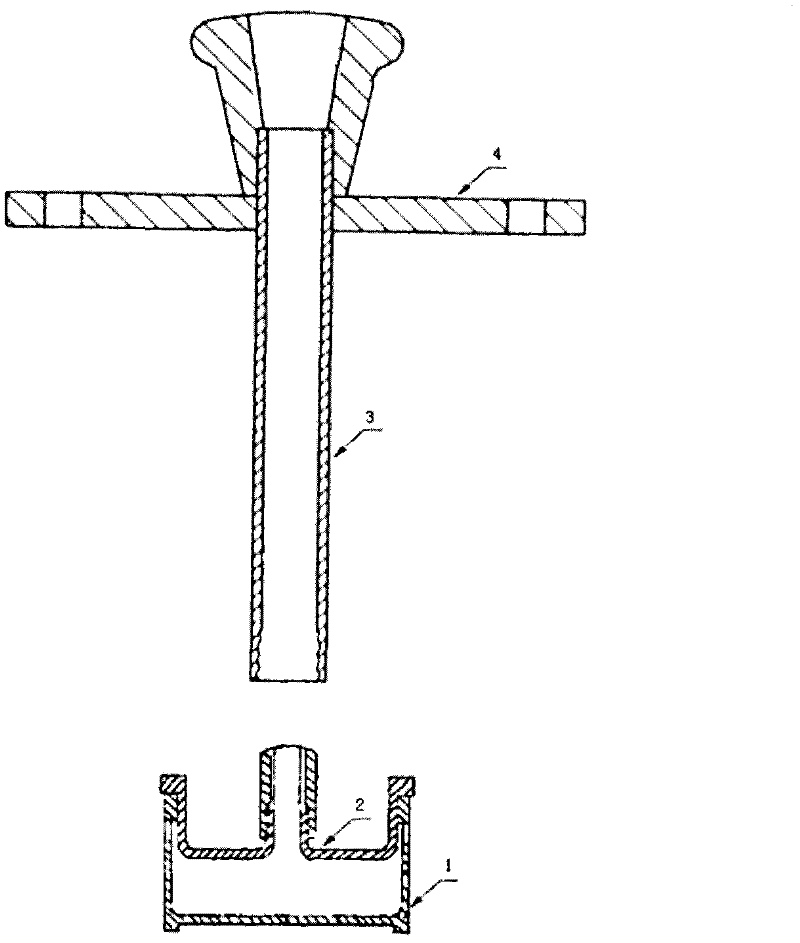

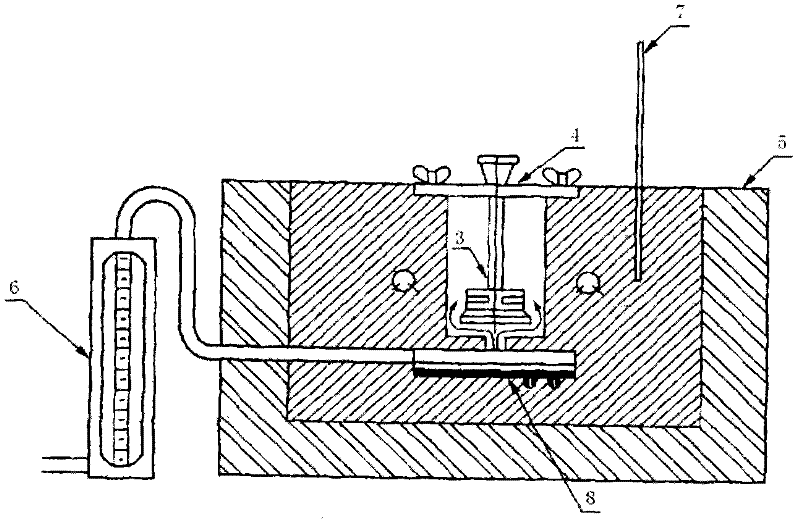

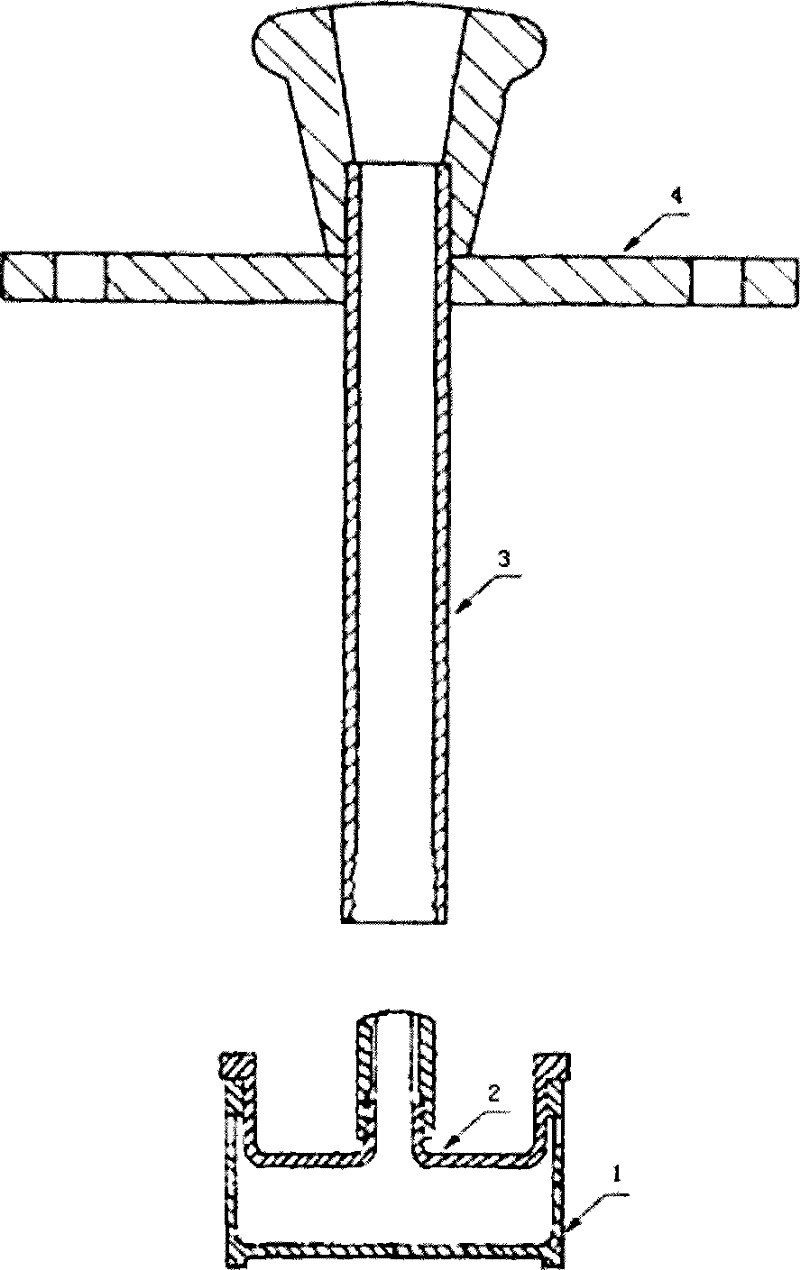

[0028] See attached Figure 1~2 As shown, the method for measuring the high-temperature evaporation loss of lubricating oil, the steps of the method are:

[0029] (1) Install the cover 4 with the exhaust pipe 3 on the aluminum block heater 5, set the aluminum block heater 5 to the test temperature and then heat it. The test temperature is 205°C, and the temperature control accuracy is ±1°C. 7 Observe that after the temperature reaches the test temperature, the air flow is introduced through the flow meter 6, and the air flow is controlled within the range of 2L / min±15.5mL / min, and the aluminum block heater 5 adopts a pressure-regulating heating and temperature control method;

[0030] (2) After the cover 4 of the exhaust pipe 3 is preheated and kept warm for 0.5h, take it out from the aluminum block heater 5, add 10±0.05g of oil sample to the sample cup 1 and install it on the exhaust pipe 3 to...

Embodiment 2

[0045] Example 2: Determination of the evaporation loss of 4050 aviation lubricating oil at 205°C

[0046] Its test process is identical with embodiment 1, and the calculation result of evaporation loss is:

[0047] X=(S-W) / S×100%=(10.0-9.395)×100%=6.05%

Embodiment 3

[0048] Example 3: Determination of evaporation loss of RC-5 fluorosilicone oil at 250°C

[0049] Its test process is identical with embodiment 1, and wherein, test temperature is 250 ℃, and the calculated result of evaporation loss is:

[0050] X=(S-W) / S×100%=(10.0-9.496)×100%=5.04%

[0051] Compared with the prior art, the method of the present invention is simple and easy to operate, and is not easily affected by heating time and different operators due to the automatic control of the instrument during the test process, so that the repeatability of the test results is good. After many tests, the repeatability error is in the range of 0.24% to 8.73%, which is lower than the regulation of SH / T 0661 method of less than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com