Light diffusing film and manufacturing method of the light diffusing film

A technology for a light diffusing film and a manufacturing method, applied in optics, optical elements, nonlinear optics, etc., can solve the problems of large fluctuation of diffusion characteristics, difficulty in exerting good incident angle dependence, and uneven reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

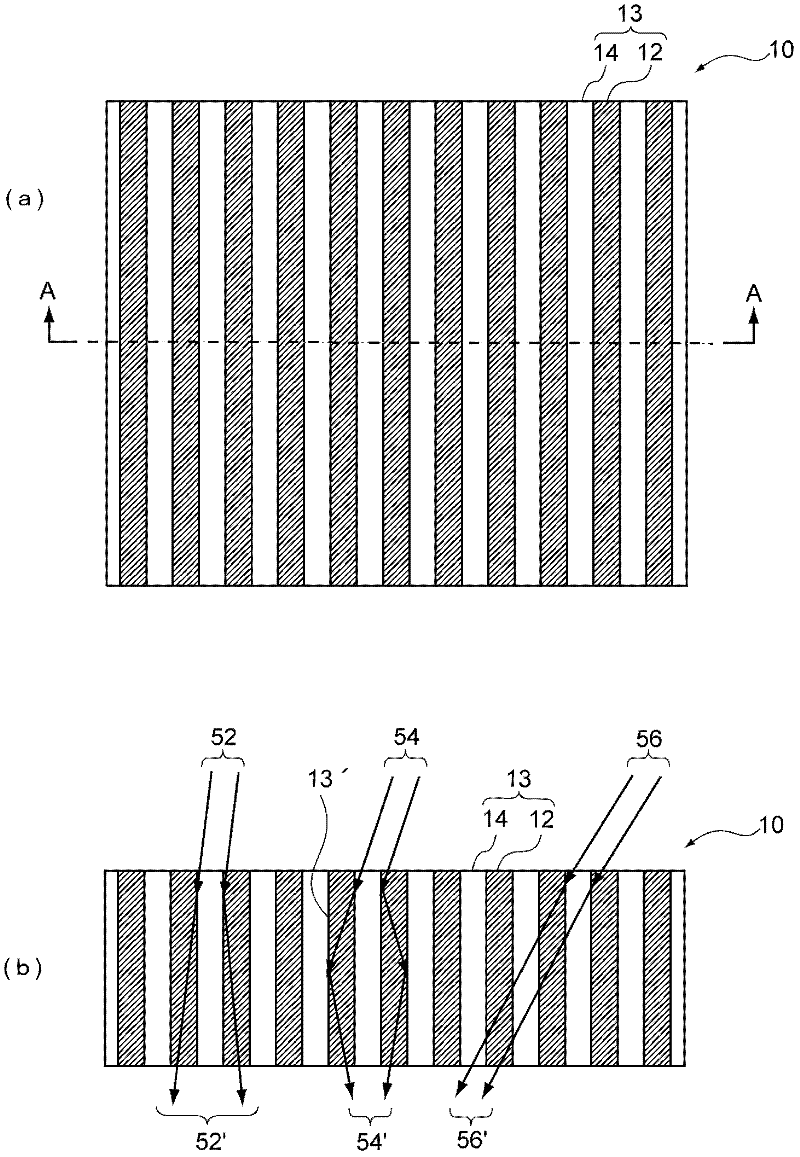

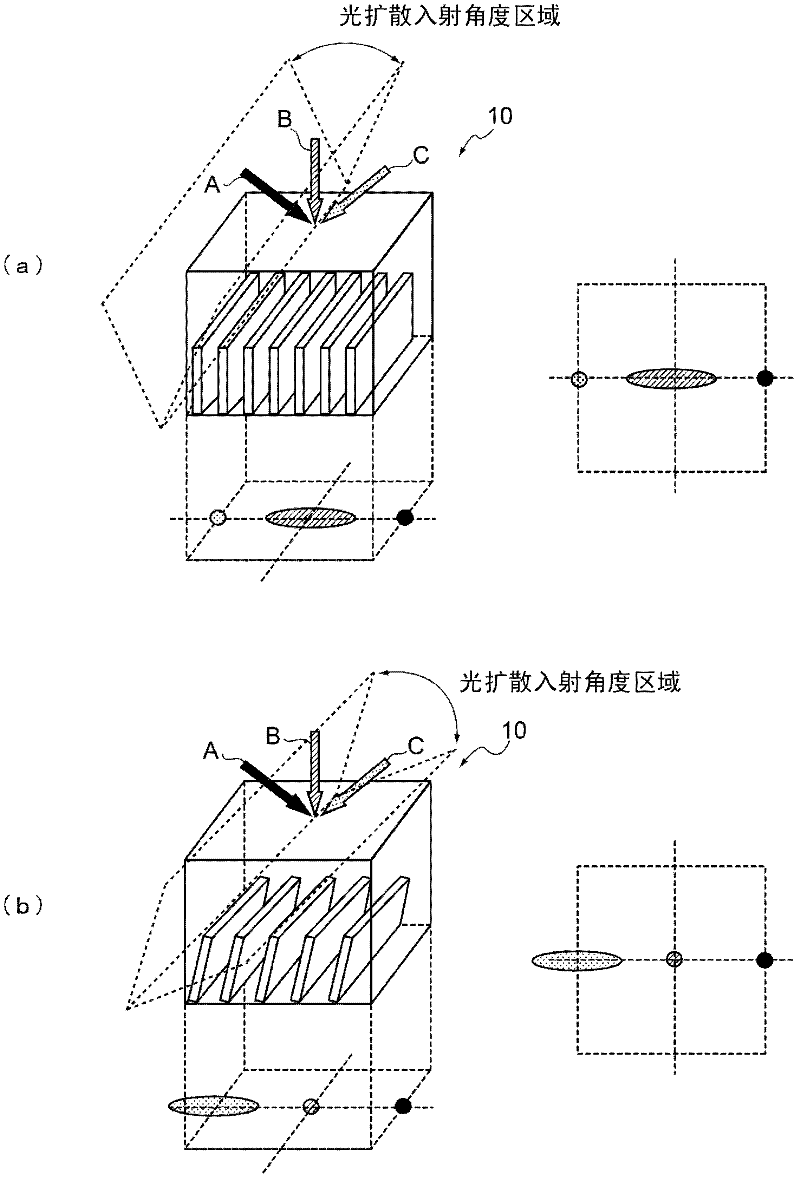

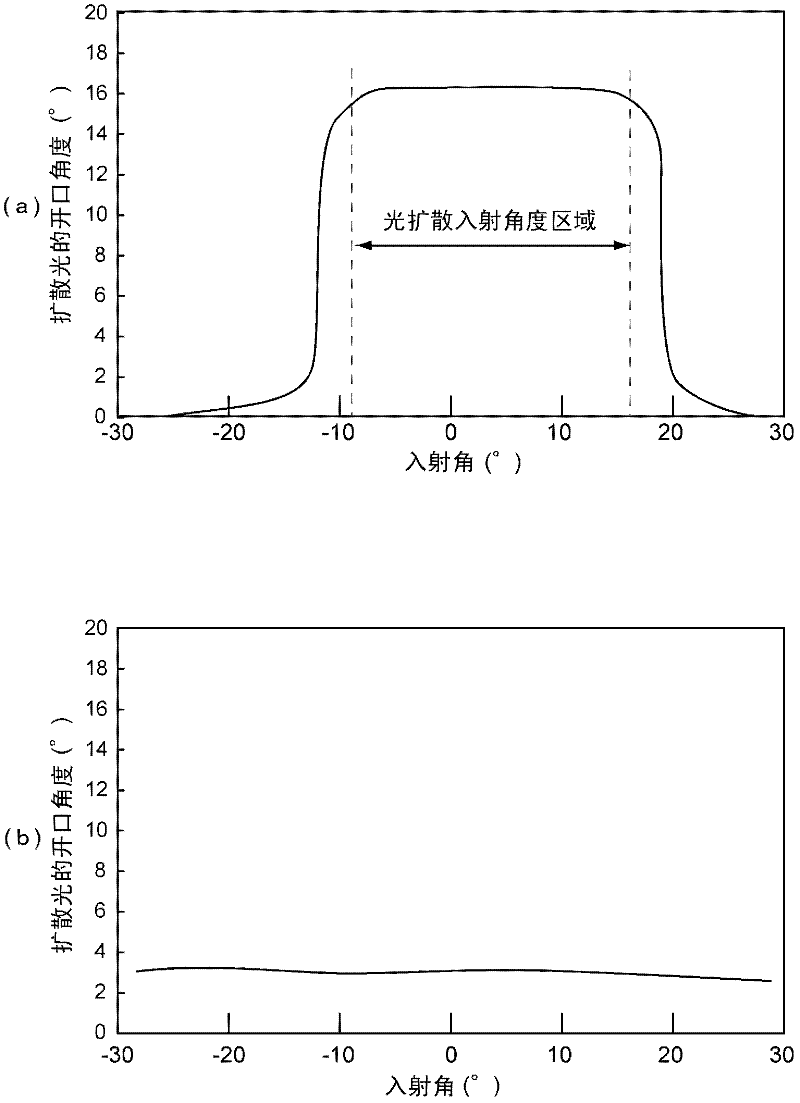

[0082] The first embodiment of the present invention is a light diffusion film having a first structure region for diffusing incident light anisotropically and a second structure region for diffusing incident light isotropically, which It is characterized in that the first structure area is a louver structure area formed by alternately arranging a plurality of plate-shaped areas with different refractive indexes in parallel along the film surface direction, and the second structure area is a louver structure area in which the refractive index and the medium stand in the medium. A column structure area formed by different columns.

[0083] Hereinafter, the first embodiment of the present invention will be specifically described with reference to the drawings as appropriate.

[0084] 1. Basic principles

[0085] Hereinafter, the basic principles of the light diffusion by the louver structure and the light diffusion by the pillar structure in the light diffusion film will be described ...

no. 2 approach

[0339] The second embodiment of the present invention is a method of manufacturing a light-diffusion film, which has a first structure region for anisotropically diffusing incident light and a second structure region for isotropically diffusing incident light The method of manufacturing a light-diffusing film of is characterized by including the following steps (a) to (d).

[0340] (a) The process of preparing a composition for a light diffusion film;

[0341] (b) A process of applying the composition for a light diffusion film to an engineering sheet to form a coating layer;

[0342] (c) The coating layer is irradiated with a first active energy ray, and a first structure region is formed in the lower part of the coating layer. A plurality of plate-shaped regions with different refractive indexes are alternately arranged in parallel along the film surface direction. The blind structure area, and the process of not forming the blind structure area remains on the upper part of the co...

Embodiment 1

[0437] 1. Synthesis of monomer (B) component

[0438] In the container, 2 moles of isophorone diisocyanate (IPDI) as component (a) and (c) component are contained relative to 1 mole of polypropylene glycol (PPG) with a weight average molecular weight of 9,200 as component (b) After 2 moles of 2-hydroxyethyl methacrylate (HEMA), polymerized according to a conventional method to obtain a polyether urethane methacrylate with a weight average molecular weight of 9,900.

[0439] In addition, the weight average molecular weights of polypropylene glycol and polyether urethane methacrylate are polystyrene conversion values measured by gel permeation chromatography (GPC) under the following conditions.

[0440] ●GPC measuring device: Tosoh Co., Ltd. product, HLC-8020

[0441] ●GPC pillar: Tosoh Co., Ltd. (listed in the order of passage below)

[0442] TSK guard column HXL-H

[0443] TSK gel GMHXL(×2)

[0444] TSK gel G2000HXL

[0445] ●Measuring solvent: Tetrahydrofuran

[0446] ●Measurement temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com