Laminated structure of radio frequency transformer

A radio frequency transformer and stacking technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of small mutual inductance, limited application of radio frequency transformer, and large distance between primary and secondary metal coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

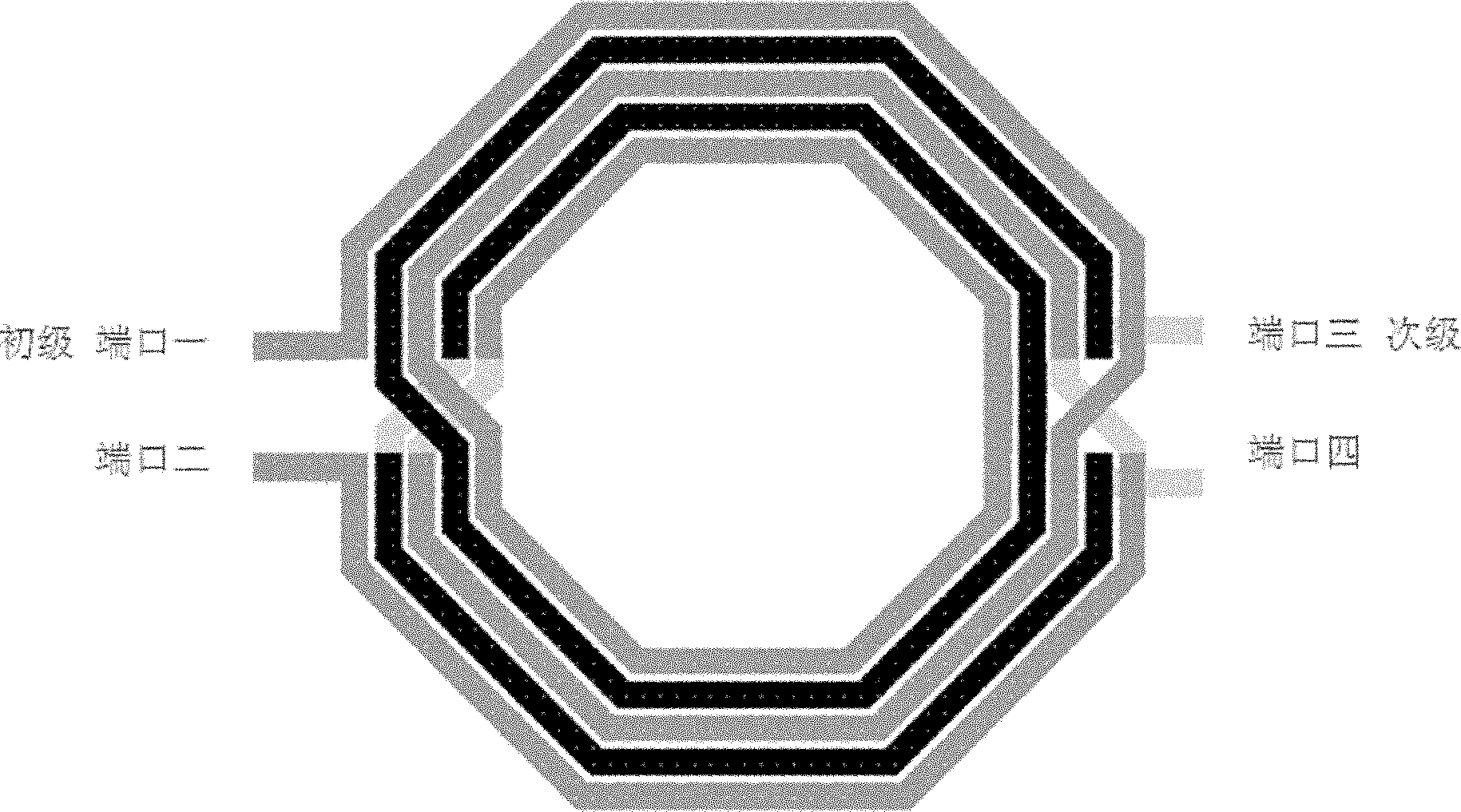

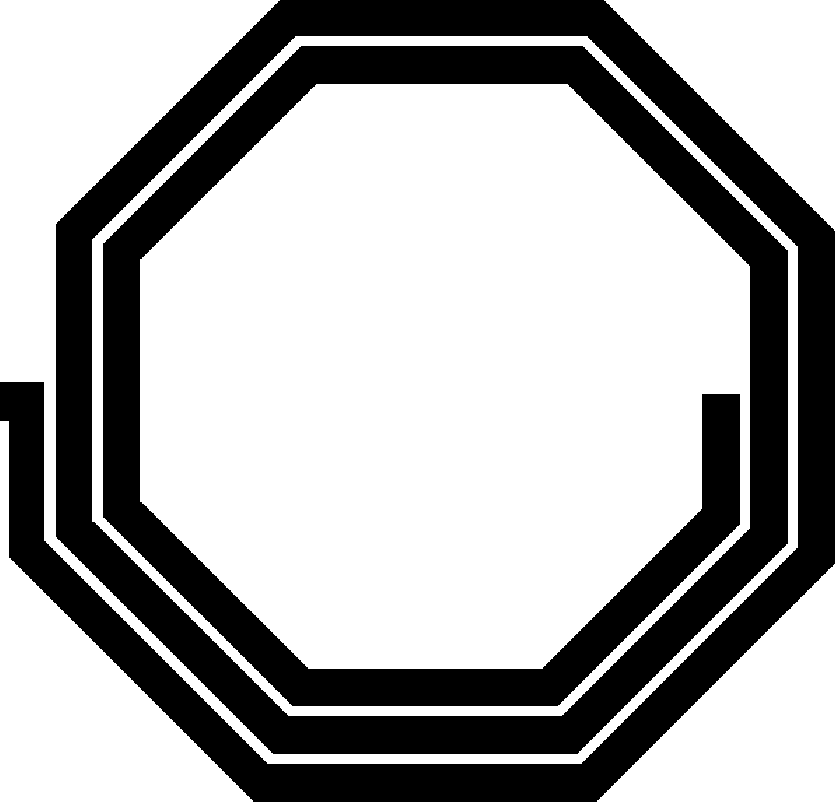

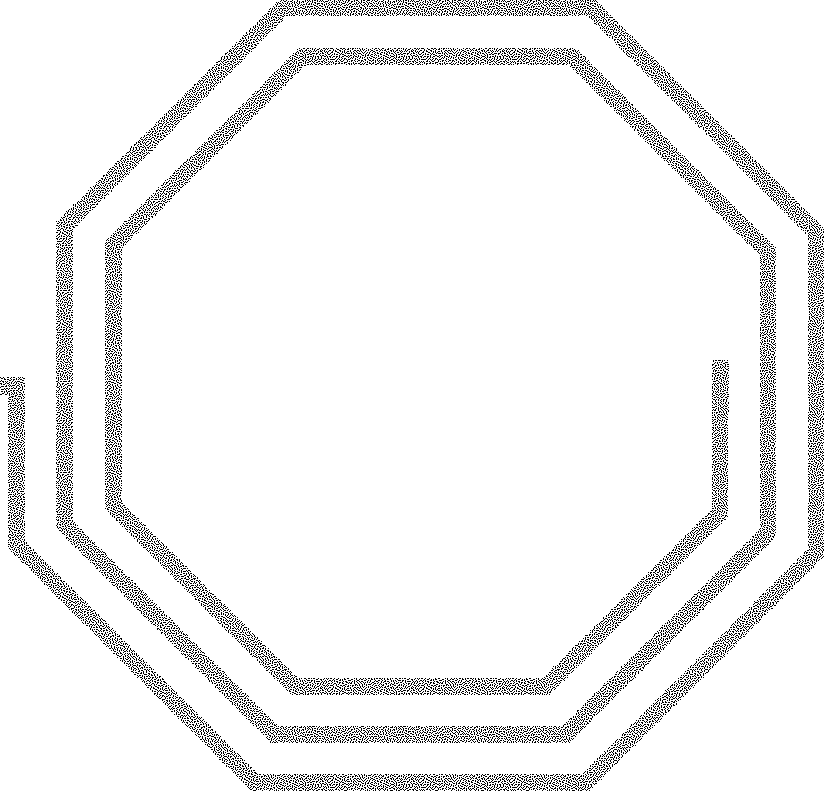

[0022] Now give a preferred embodiment to illustrate the present invention. The laminated radio frequency transformer of the present invention comprises three layers: a metal coil 1 at the top layer, a metal coil 3 at the middle layer and a metal coil 2 at the bottom layer. Such as figure 2 Shown is a schematic diagram of the planar structure of the top metal coil 1 and the bottom metal coil 2, the top metal coil 1 and the bottom metal coil 2 both have coil patterns in the plane, the coil patterns of the two are completely consistent and have the same strip width ws, The top metal coil 1 and the bottom metal coil 2 are used as secondary metal coils for realizing mutual inductance; image 3 Shown is a schematic diagram of the plane structure of the middle layer metal coil 3, which also has a coil pattern in the plane, and the pattern is completely consistent with the top layer metal coil 1, and its strip width is ws1, and ws>ws1, which is used as the primary metal coil for mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com