Intermetallic compound filled vertical through-hole interconnecting structure for three-dimensional package and preparation method thereof

A technology of intermetallic compounds and three-dimensional packaging, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of poor conductivity of solder, low melting point of solder, poor conductivity, etc., and achieve the goal of manufacturing The process is convenient, the pass rate is improved, and the production cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific drawings and embodiments.

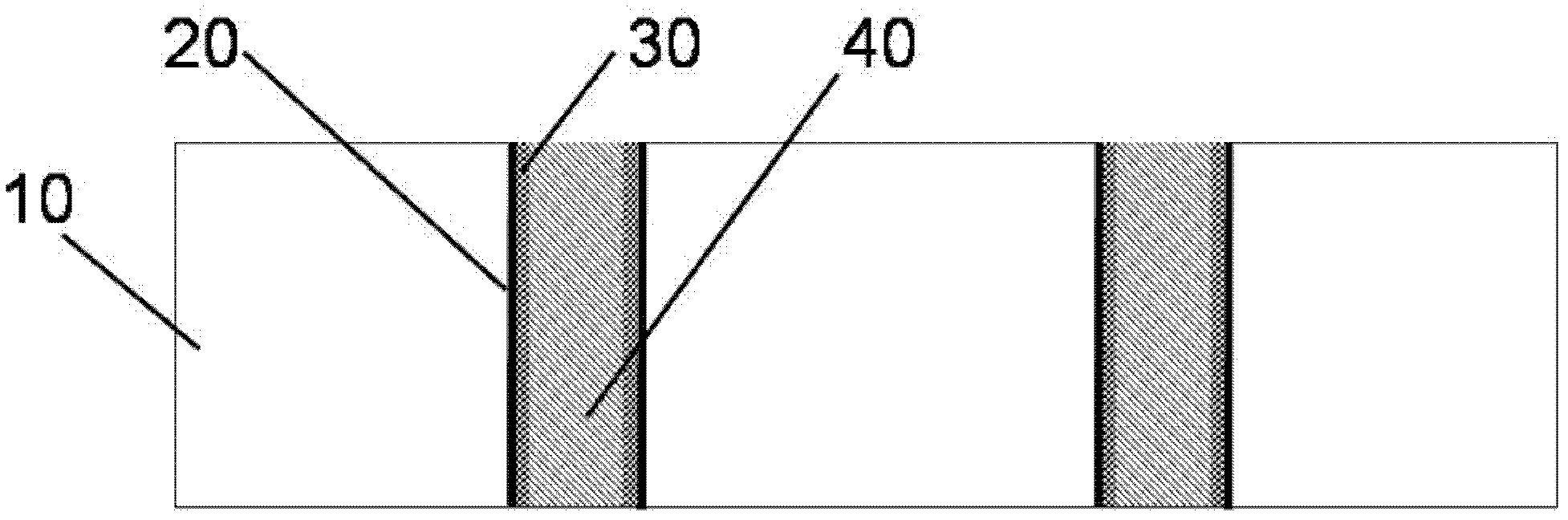

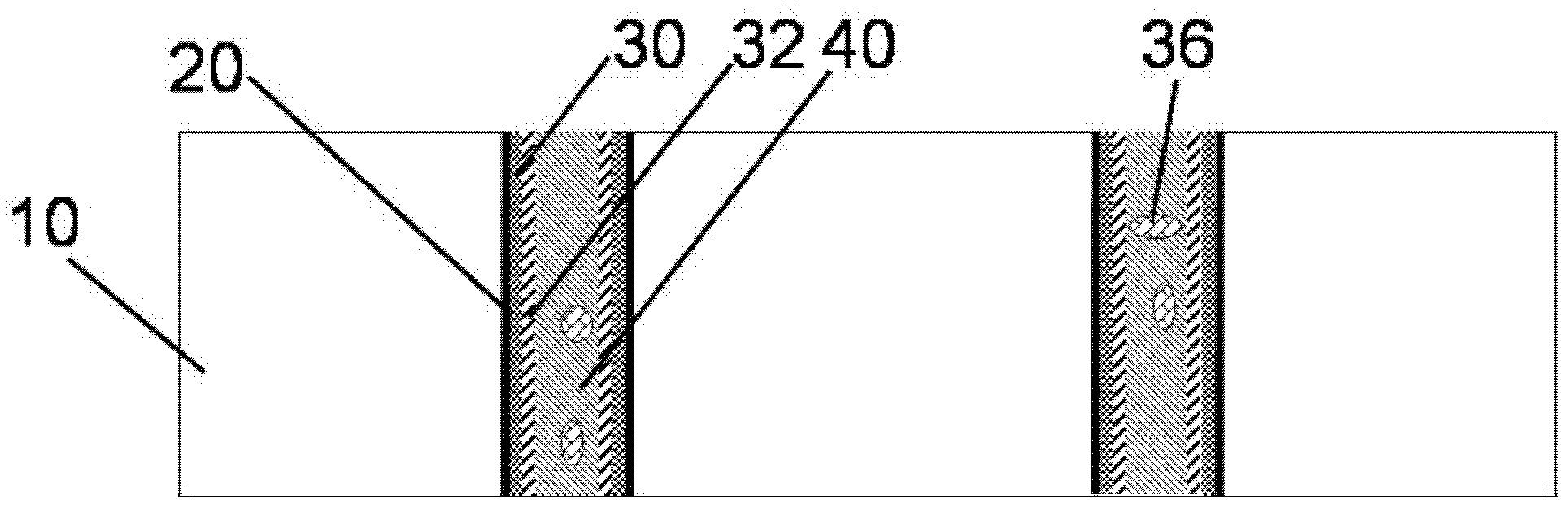

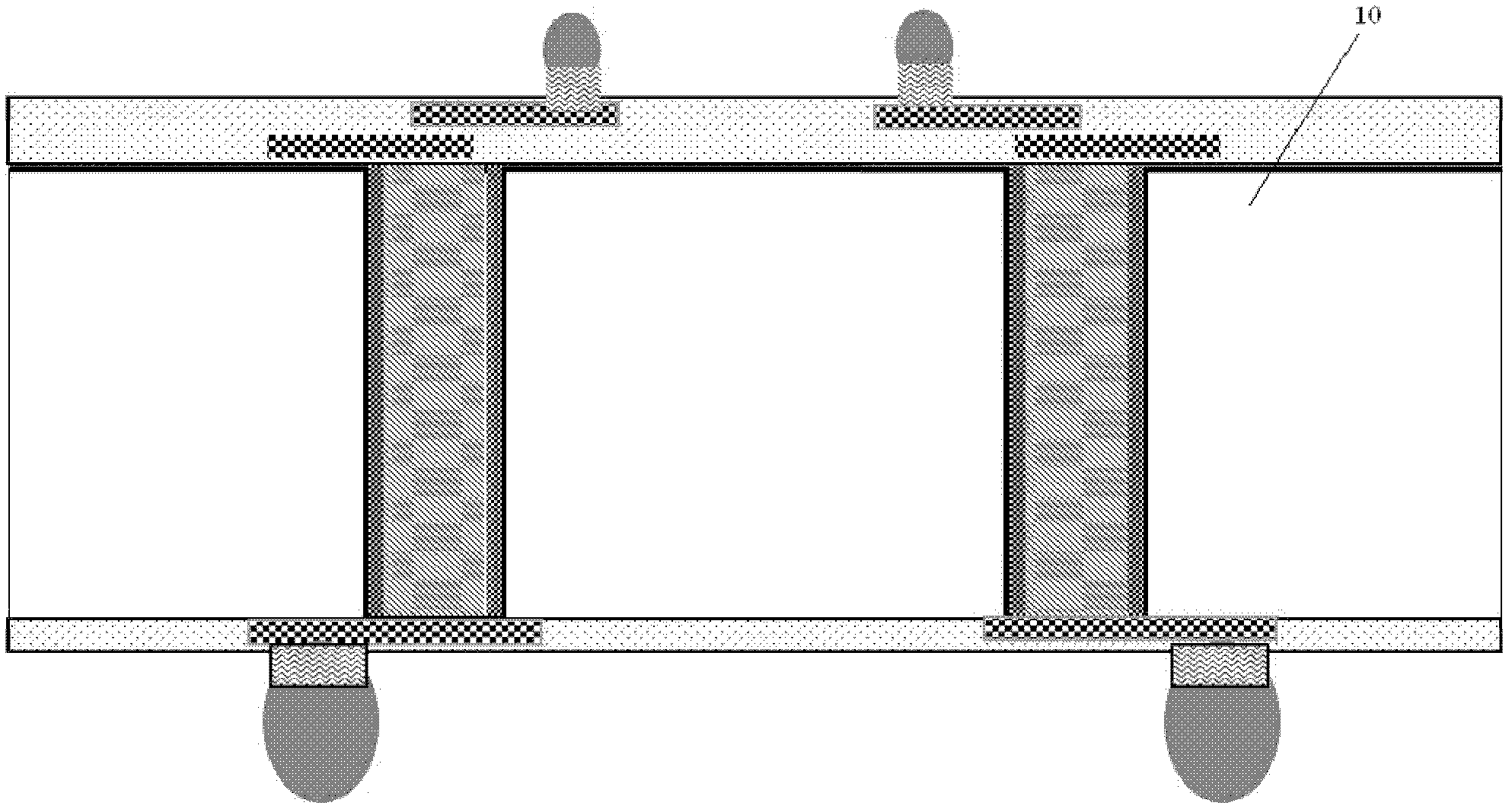

[0044] like figure 1 , figure 2 , Figure 9 and Figure 10 As shown: the vertical interconnection structure in the present invention includes a substrate 10, and the material of the substrate 10 is silicon, gallium arsenide, gallium nitride or glass, and at least one vertical through substrate is arranged in the substrate 10 10 through holes 12 . In order to realize interconnect packaging, when the substrate 10 is a conductor or semiconductor material, an insulating layer 20 is grown on the inner wall of the through hole 12, and the insulating layer 20 is SiO 2 , Si x N 1-x one or more of them. The through hole 12 with the insulating layer 20 grown on the inner wall is filled with an intermetallic compound layer 40, an adhesion layer 30 is provided between the intermetallic compound layer 40 and the insulating layer 20, and the intermetallic compound la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com