Micro electronic mechanical system (MEMS) load line type 2-bit phase shifter based on left-handed transmission line

A left-handed transmission line, line-type technology, applied in waveguide-type devices, coupling of optical waveguides, components of TV systems, etc., can solve the problems of small phase shift and large number of switches in MEMS switches, and achieve fewer switches and fewer switches. The effect of using quantity and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

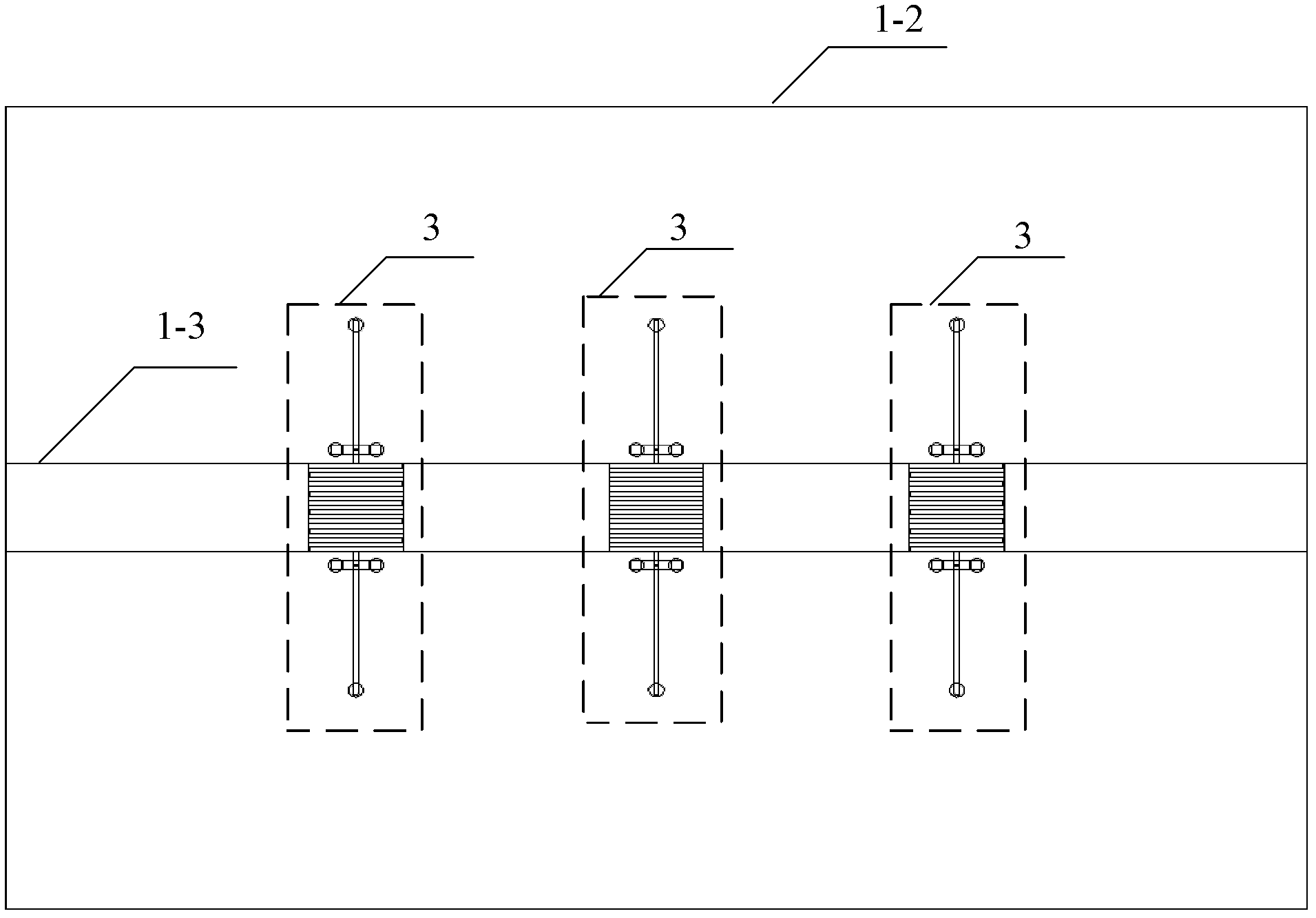

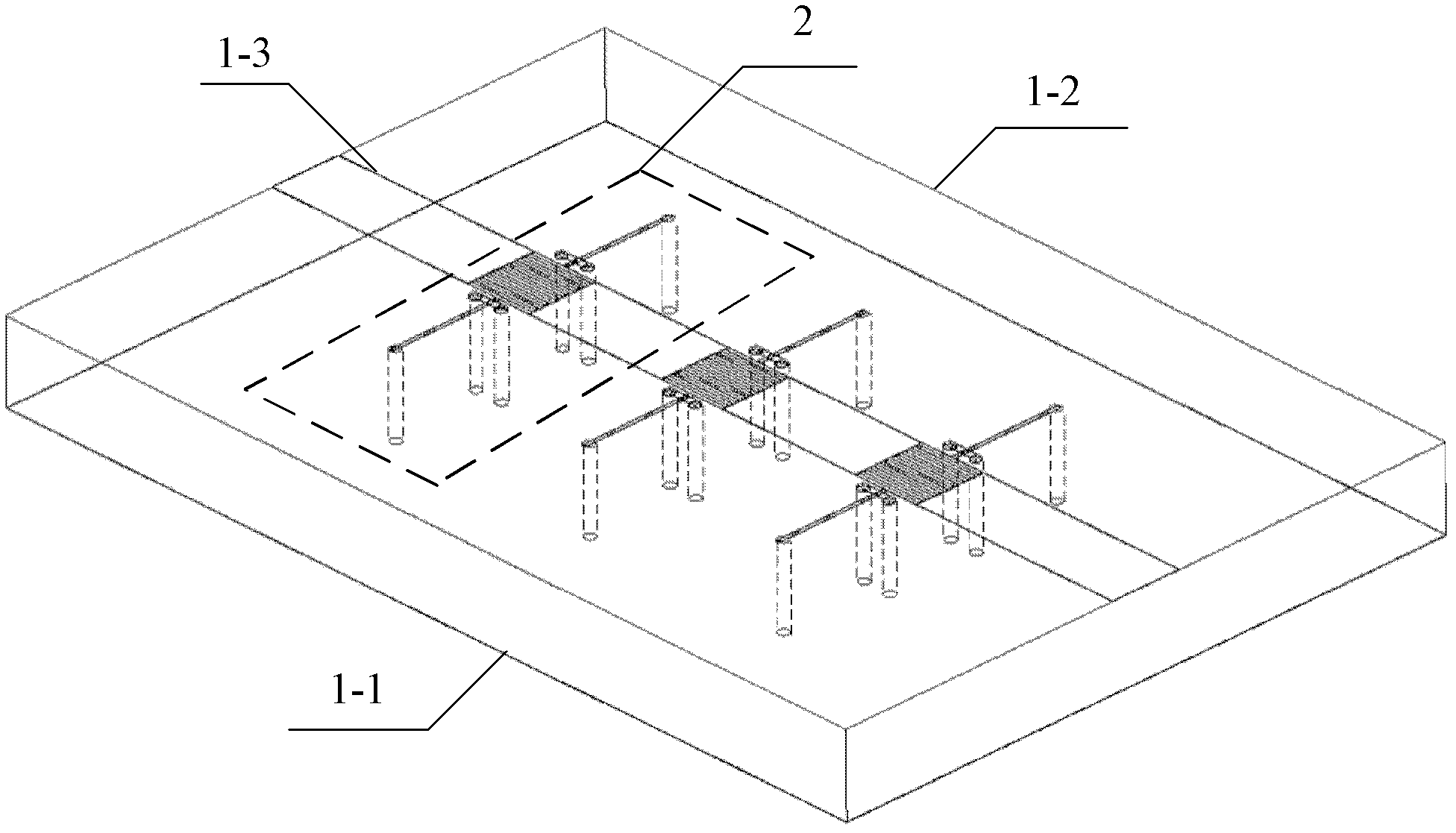

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Describe this embodiment, the MEMS load line type 2 phase shifter based on the left-hand transmission line described in this embodiment, it includes a microstrip line 1 and three groups of phase shifting units 2; the microstrip line 1 includes a ground plate covered with a metal layer 1-1, the base 1-2 and the signal line 1-3, the signal line 1-3 is fixed on the upper surface of the base 1-2, and is located in the middle of the base 1-2 along the width direction, the signal line 1-3 is divided into Four sections, each adjacent two sections are electrically connected through a phase shifting unit 2;

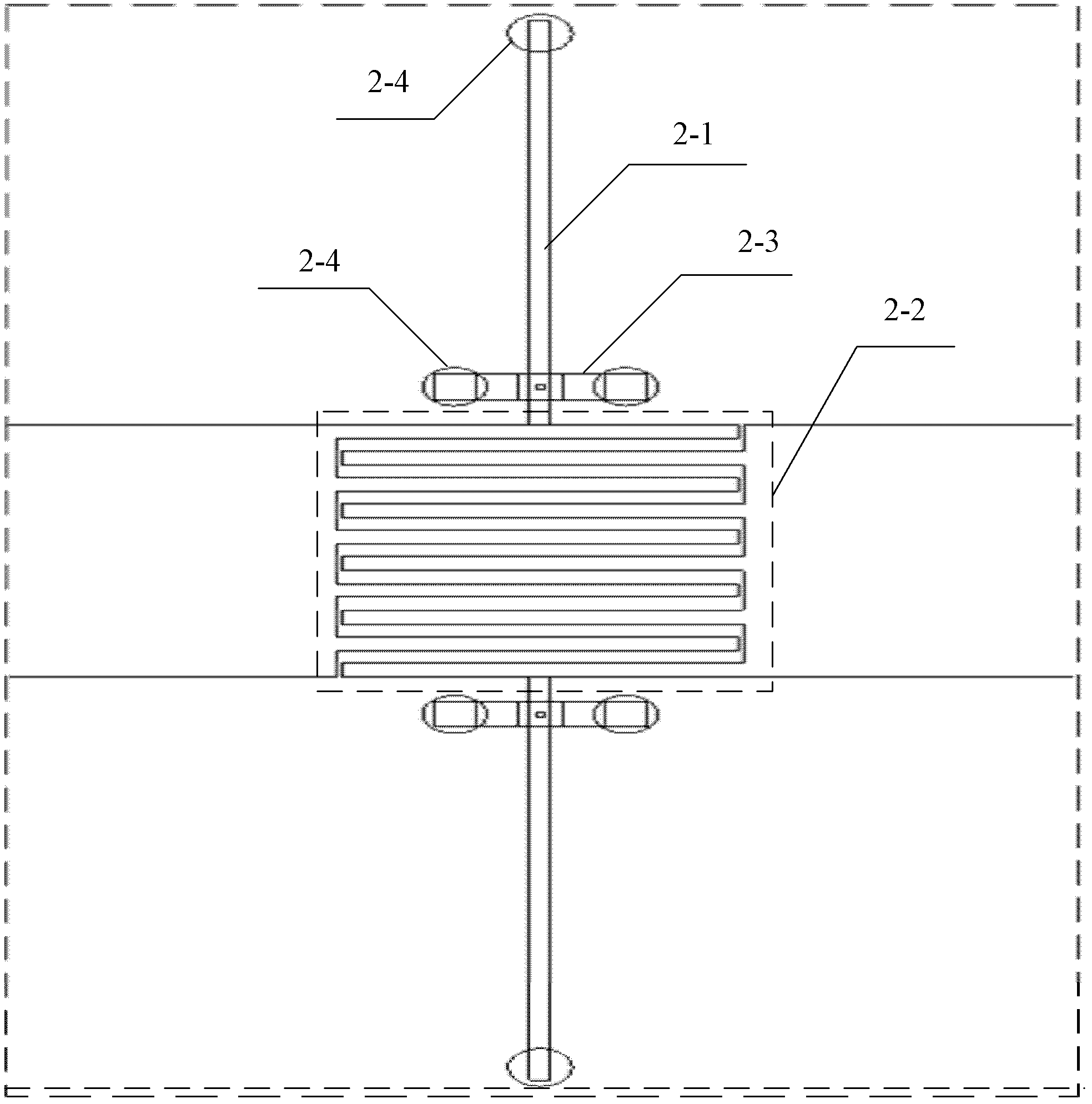

[0018] The phase shifting unit 2 includes a stub 2-1, an interdigitated capacitor 2-2, a MEMS switch 2-3 and a cylindrical metal via 2-4; the stub 2-1 and the interdigitated capacitor 2-2 form a left-hand transmission line the structural unit;

[0019] A stub 2-1 and a...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and the MEMS load line type 2 phase shifter based on the left-hand transmission line described in Embodiment 1 is that the distance between the centers of adjacent single phase shifting units 2 is 800 μm.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from the MEMS load line type 2 phase shifter based on the left-hand transmission line described in Embodiment 1 in that the length of the phase shifter is 3.0mm, the width is 1.8mm, and the height is 0.234mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com