Permanent magnet harmonic motor

A harmonic motor and permanent magnet technology, which is applied to motors, synchronous motors with stationary armatures and rotating magnets, synchronous machines, etc., can solve the problems of large number of components and complex structures of harmonic motors, and reduce non-spring The effect of load quality, simple assembly process, and large torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

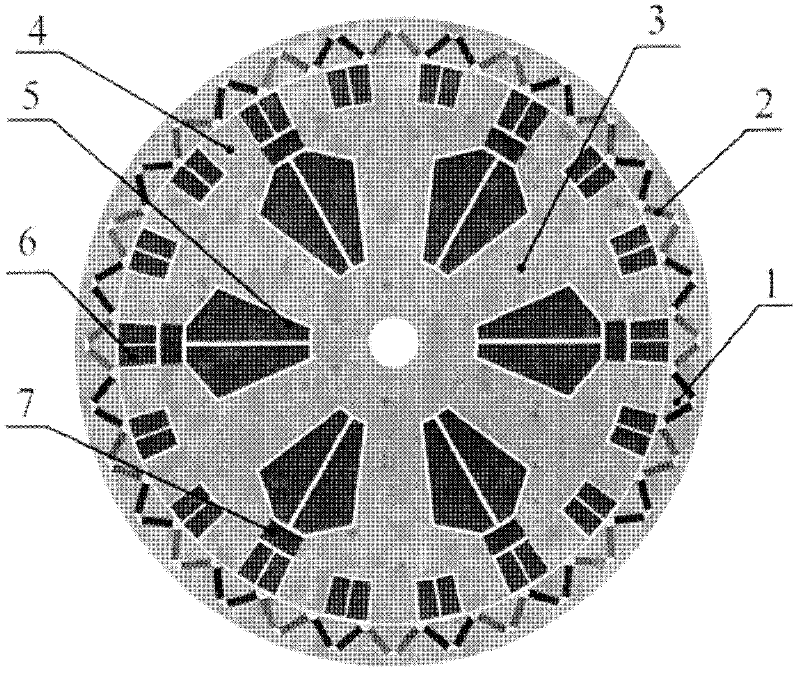

[0036] Such as figure 1 The permanent magnet harmonic motor shown includes: a rotor mechanism 1 with a number of permanent magnets 2 provided on the rotor mechanism 1; the shape of the permanent magnets 2 can be many kinds, of which, preferably rectangular; the permanent magnets 2 and There are many kinds of connection relationships of the rotor mechanism, among which, it is preferably embedded in the rotor mechanism. When the rotor is rotating at a high speed, the permanent magnets are not easy to fall; in addition, the permanent magnets 2 may be distributed There are many types, among them, it is preferably a V-shaped distribution, and the magnetic poles of every two adjacent V-shaped permanent magnets 2 are opposite; the harmonic motor also includes a stator mechanism 3 that cooperates with the rotor mechanism 1, wherein the stator mechanism 3 has an air gap with the rotor mechanism 1; it also includes a supporting mechanism 8, on which a bearing assembly 10 is provided, and ...

Embodiment 2

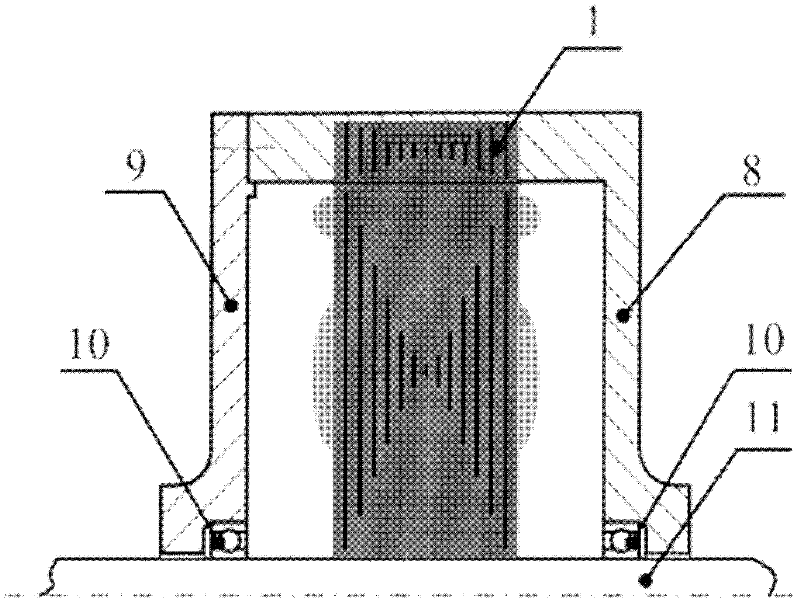

[0048] Such as Figure 5 with Image 6 In the permanent magnet harmonic motor shown, the difference between the motor of this embodiment and the first embodiment is that the rotor mechanism is an inner rotor mechanism, and the stator mechanism is an outer stator mechanism.

[0049] See Image 6 In this embodiment, the outer stator, the supporting mechanism 8 and the end cover 9 are respectively fixed on the outer ring of the bearing assembly 10. The rotor is fixed on the shaft 11, and the supporting mechanism may be a cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com