Aluminium brazing sheet

A plate and brazing technology, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problem of waste disposal, etc., and achieve the effect of eliminating cost, good working environment and saving workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] According to one embodiment, the chemical composition of the thin cladding material comprises

[0056] Bi 0.01-1.0 wt%, preferably 0.05-0.7 wt%, more preferably 0.07-0.5 wt%,

[0057] Mg≤0.05% by weight, preferably ≤0.01% by weight, more preferably 0%,

[0058] Mn≤1.0% by weight,

[0059] Cu≤1.2% by weight,

[0060] Fe≤1.0% by weight,

[0061] Si ≤ 1.9% by weight, preferably ≤ 1.65% by weight, more preferably ≤ 1.4% by weight, most preferably ≤ 0.9% by weight,

[0062] Ti≤0.1% by weight,

[0063] Zn≤6 wt%, Sn≤0.1 wt%, In≤0.1 wt%, and

[0064] Unavoidable impurities each contained less than 0.05% by weight, and the total impurity content was less than 0.2% by weight, with the balance being Al.

[0065] A Si content of 1.9 wt% or less in the thin cladding layer will help the cladding layer to be in a solid state when the solder layer melts, and thus also facilitate wettability and joint formation. Pure aluminum may contain up to 1.65% Si in solid solution at 577°C ...

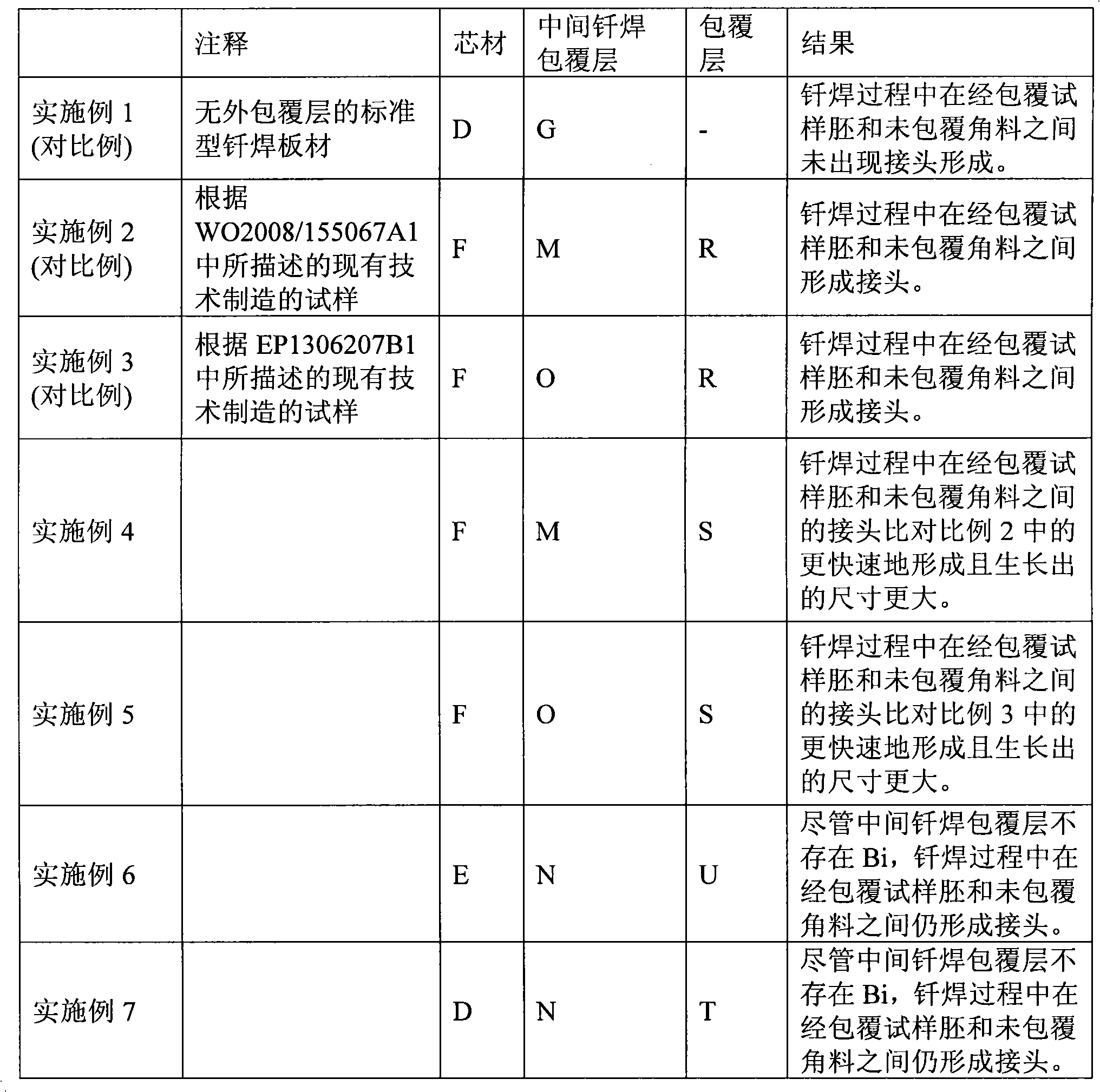

Embodiment

[0073] All alloys were cast by laboratory casting equipment into so-called stack molds, which were produced into small slabs with a length of 150 mm, a width of 90 mm and a thickness of 20 mm. Table 1 shows the chemical composition of the alloys used to test brazeability.

[0074] Each slab was trimmed, heated from room temperature to 450°C over 8 hours, held at 450°C for 2 hours, and cooled in ambient air. The material is then rolled to the appropriate thickness, with soft annealing between steps when required for easier rolling. The core material-intermediate brazing layer-outer layer material is then combined into a three-layer clad pack, and the layers in the composite pack are brought into contact with each other by cold rolling. The material was cold rolled to a thickness of 0.4mm, this provided a single sided cladding with 8% middle layer and 2% outer layer with an intermediate softening anneal when required to provide easy rolling and give a final back anneal , so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com