Alloyed hot-dip galvanized steel sheet and manufacturing method therefor

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in the direction of hot-dip galvanizing process, chemical instruments and methods, coating of superimposed layers, etc., can solve the problems that the r value cannot be improved, and achieve excellent deep drawing properties , Excellent formability, high formability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

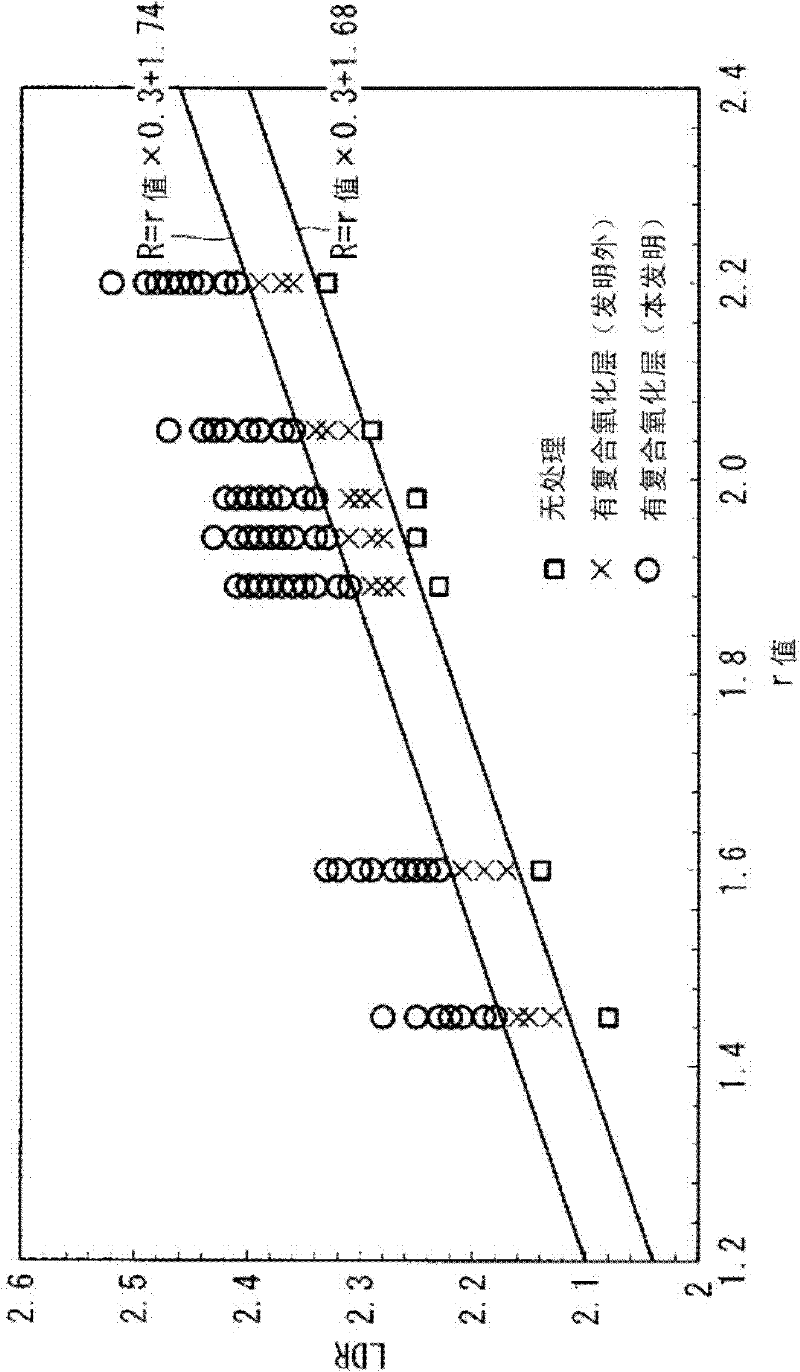

[0125] Heating the slab with the composition of Table 1 (very low carbon steel) to 1150°C, hot-rolling at a finish rolling temperature of 910-930°C, making a 4mm hot-rolled steel strip, and coiling it at 680-720°C around the hot rolled steel strip. After pickling, the hot-rolled steel strip was subjected to cold rolling to produce a 0.8 mm cold-rolled steel strip. Furthermore, the cold-rolled steel strip is annealed, plated, and alloyed using continuous hot-dip galvanizing equipment with an in-line annealing method to manufacture alloyed hot-dip galvanized steel sheets. During plating, the annealing atmosphere was set at 5 vol% hydrogen+95 vol% nitrogen mixed gas, the annealing temperature was set at 800-840° C., and the annealing time was set at 90 seconds. As the molten zinc bath, use a coating bath with an effective Al concentration in the bath (Al concentration that can be used as metal) of 0.105%, and use an air brush (gas wiper) to adjust the reference amount of zinc to...

Embodiment 2

[0171] The slab having the composition marked C in Table 1 is heated to 1150°C, hot-rolled at a finish rolling temperature of 910-930°C to produce a 4mm hot-rolled steel strip, and the hot-rolled steel strip is coiled at 680-720°C. Rolled steel strip. After pickling, the hot-rolled steel strip was subjected to cold rolling to produce a 0.8 mm cold-rolled steel strip. Furthermore, the cold-rolled steel strip is annealed, plated, and alloyed using continuous hot-dip galvanizing equipment with an in-line annealing method to manufacture alloyed hot-dip galvanized steel sheets. During plating, the annealing atmosphere was set at 5 vol% hydrogen+95 vol% nitrogen mixed gas, the annealing temperature was set at 800-840° C., and the annealing time was set at 90 seconds. As a molten zinc bath, use a coating bath with an effective Al concentration in the bath of 0.105%, and use an air brush to adjust the reference amount of zinc to 50g / m 2 . For alloying heating, alloying is performed...

Embodiment 3

[0185] A slab having a composition marked D in Table 1 is heated to 1150°C, hot-rolled at a finish rolling temperature of 910-930°C, and a 4mm hot-rolled steel strip is produced, and the hot-rolled steel strip is coiled at 680-720°C. Rolled steel strip. After pickling, the hot-rolled steel strip was subjected to cold rolling to produce a 0.8 mm cold-rolled steel strip. Furthermore, the cold-rolled steel strip is annealed, plated, and alloyed using continuous hot-dip galvanizing equipment with an in-line annealing method to manufacture alloyed hot-dip galvanized steel sheets. During plating, the annealing atmosphere was set at 5 vol% hydrogen+95 vol% nitrogen mixed gas, the annealing temperature was set at 800-840° C., and the annealing time was set at 90 seconds. As a molten zinc bath, use a coating bath with an effective Al concentration in the bath of 0.105%, and use an air brush to adjust the reference amount of zinc to 50g / m 2 . For alloying heating, alloying is perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com