Power converting apparatus for an electric car

A power conversion device and power converter technology, applied in electric vehicles, power consumption devices, output power conversion devices, etc., can solve problems such as burnout, expansion of faulty parts of power converters, heating of synchronous machines, etc., to reduce the burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

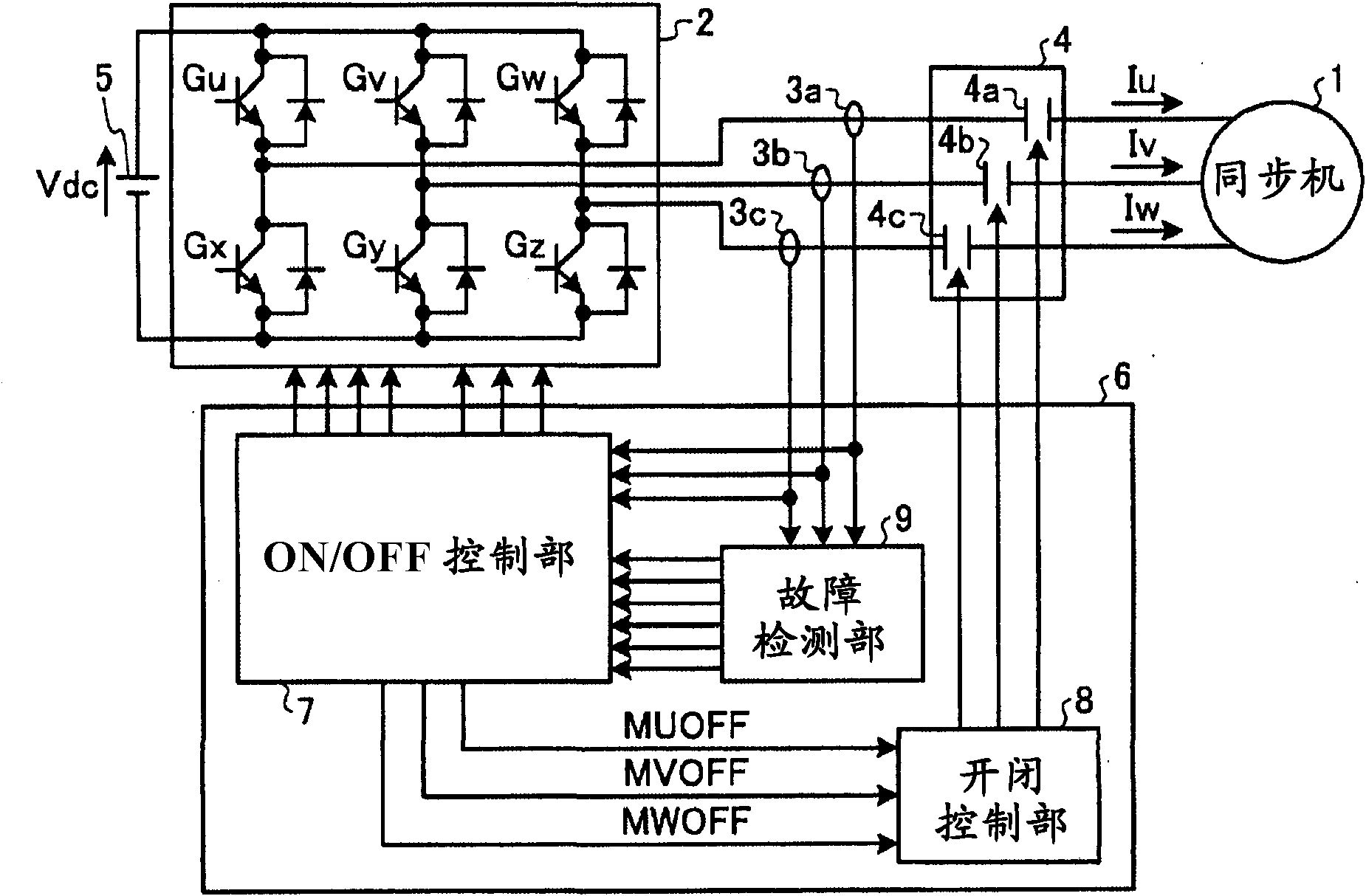

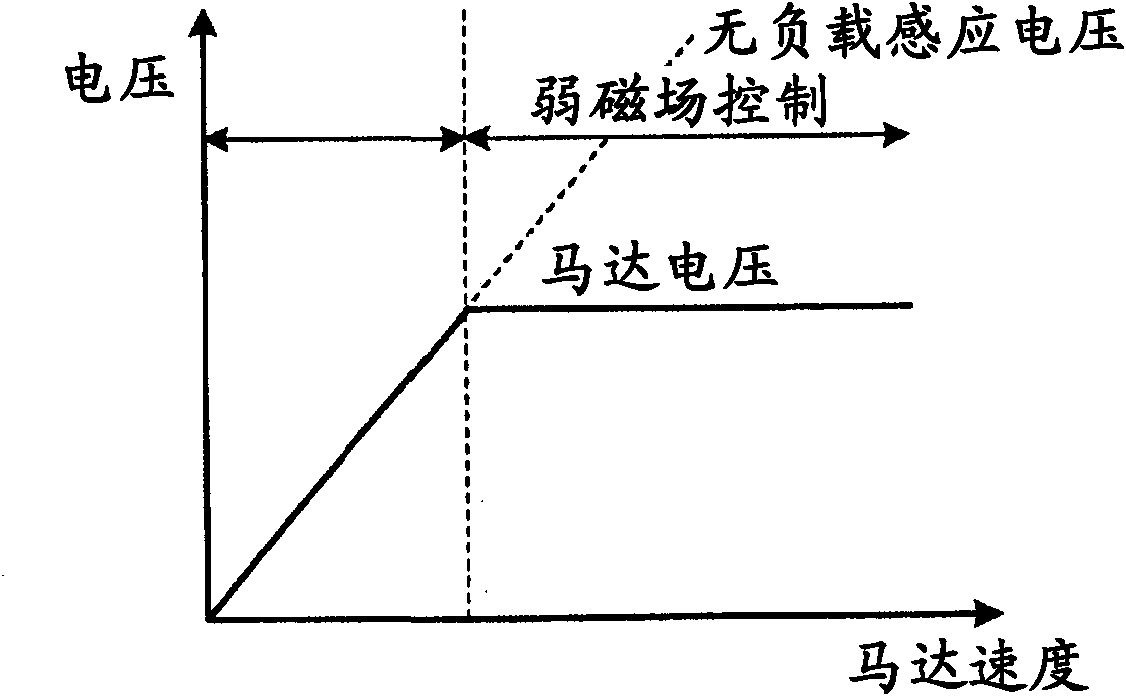

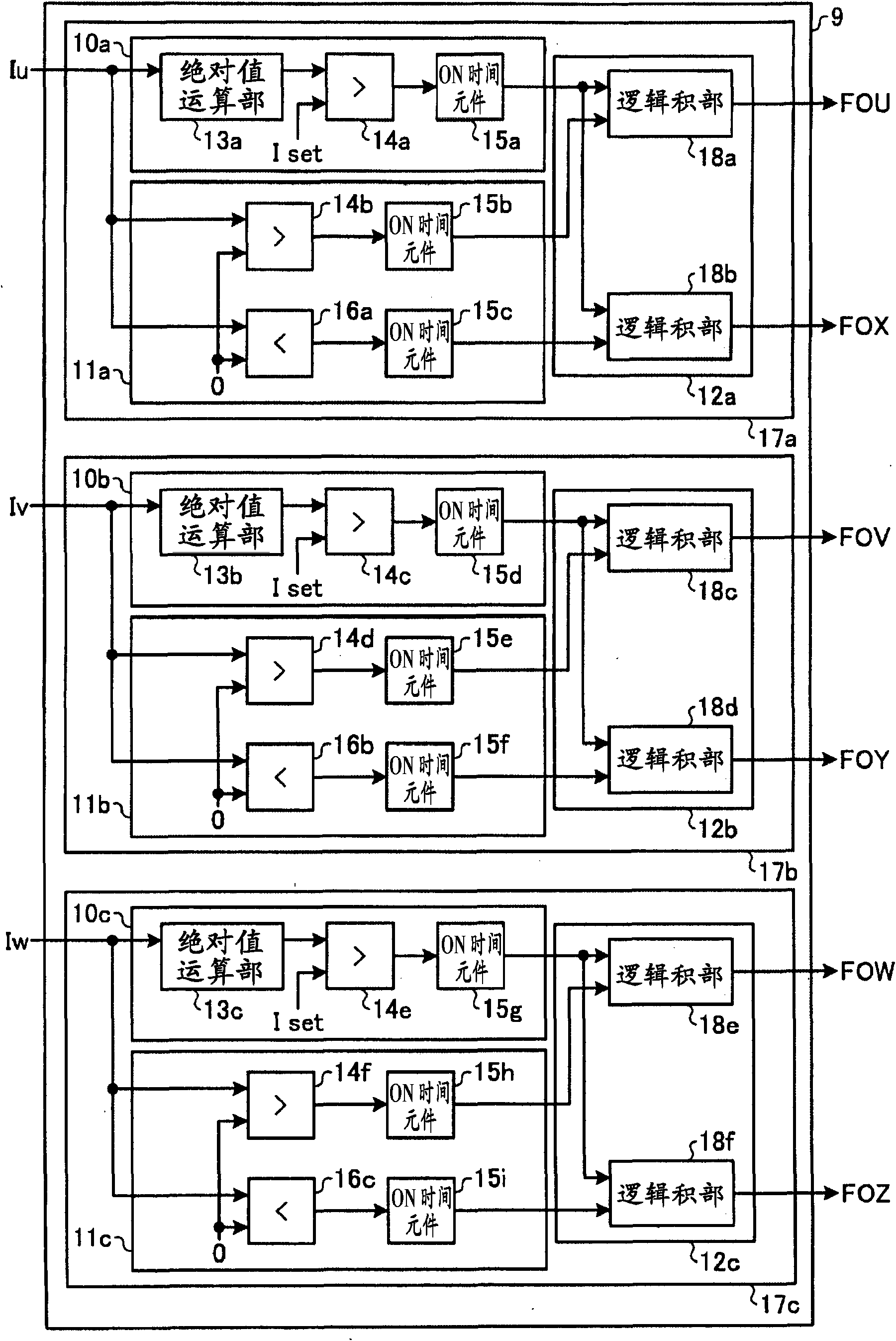

[0027] figure 1 is a diagram showing a configuration example of a power conversion device for an electric vehicle according to Embodiment 1 of the present invention, figure 2 It is a graph showing the relationship between the motor voltage and the no-load induced voltage of the synchronous machine 1 . figure 1The power conversion device of the electric vehicle shown has: a power converter 2, which is connected to a DC power supply 5 and drives the synchronous machine 1; and the control unit 6 controls the operation of the power converter 2 and the opening control of the switch unit 4 .

[0028] The power converter 2 is composed of three switching (hereinafter simply referred to as "SW") elements (U-phase upper arm element Gu, V-phase upper arm element Gv, and W-phase upper arm element Gw) of the positive side arm, and A bridge circuit of three SW elements (U-phase lower arm element Gx, V-phase lower arm element Gy, and W-phase lower arm element Gz) of the negative side arm ...

Embodiment approach 2

[0077] Figure 8 is a diagram showing one configuration of a power conversion device for an electric vehicle according to Embodiment 2 of the present invention, Figure 9 It is a figure showing another structure of the electric power conversion apparatus of the electric vehicle concerning Embodiment 2 of this invention, Figure 10 is used to illustrate the Figure 8 as well as Figure 9 The flow chart of a series of operations from when an abnormality occurs in the power converter 2 to opening the switch 4 is shown. In addition, the same code|symbol is attached|subjected to the same part as 1st Embodiment, the description is abbreviate|omitted, and only a different part is described.

[0078] The point of difference from Embodiment 1 is that only two phases (for example, U-phase and V-phase) are provided with switching units. Therefore, the opening and closing control unit 24 such as Figure 8 As shown, it is sufficient to output only 2-phase control signals. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com