Feed used lactate modified zeolite and preparing method and application thereof

A technology of modifying zeolite and lactic acid, which is applied in application, animal feed, animal feed, etc., can solve the problems of nutrient loss and insufficient antibacterial effect, and achieve the effects of improving production performance, protecting intestinal health, and improving microbial environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention will be further described below in conjunction with embodiment, but the present invention is not limited thereto. Embodiment 1: Preparation of lactic acid modified zeolite for feed

[0031] In order to explore the best modification conditions, single factor and orthogonal experiments were carried out, the specific steps and results are shown below; among them, the content of clinoptilolite in natural zeolite is not less than 60%.

[0032] Test 1: Single factor test

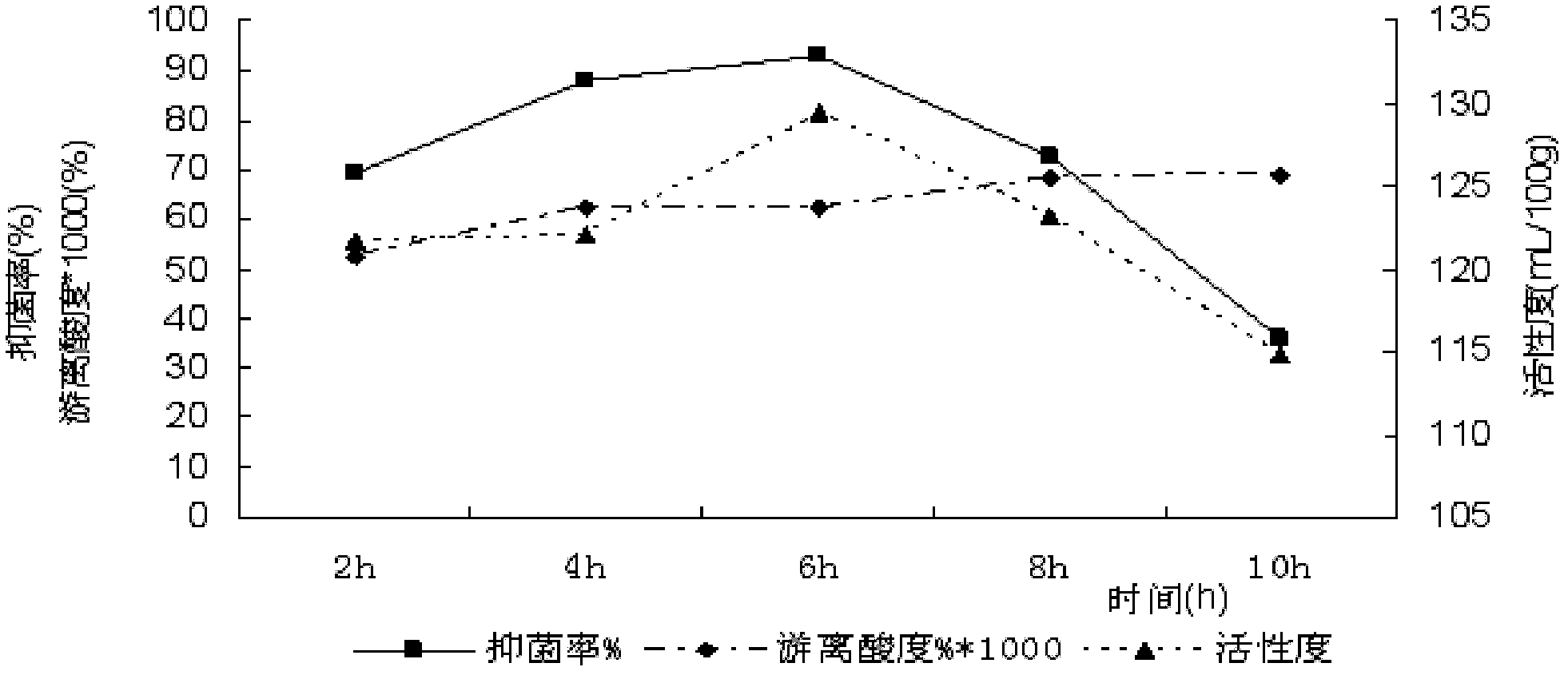

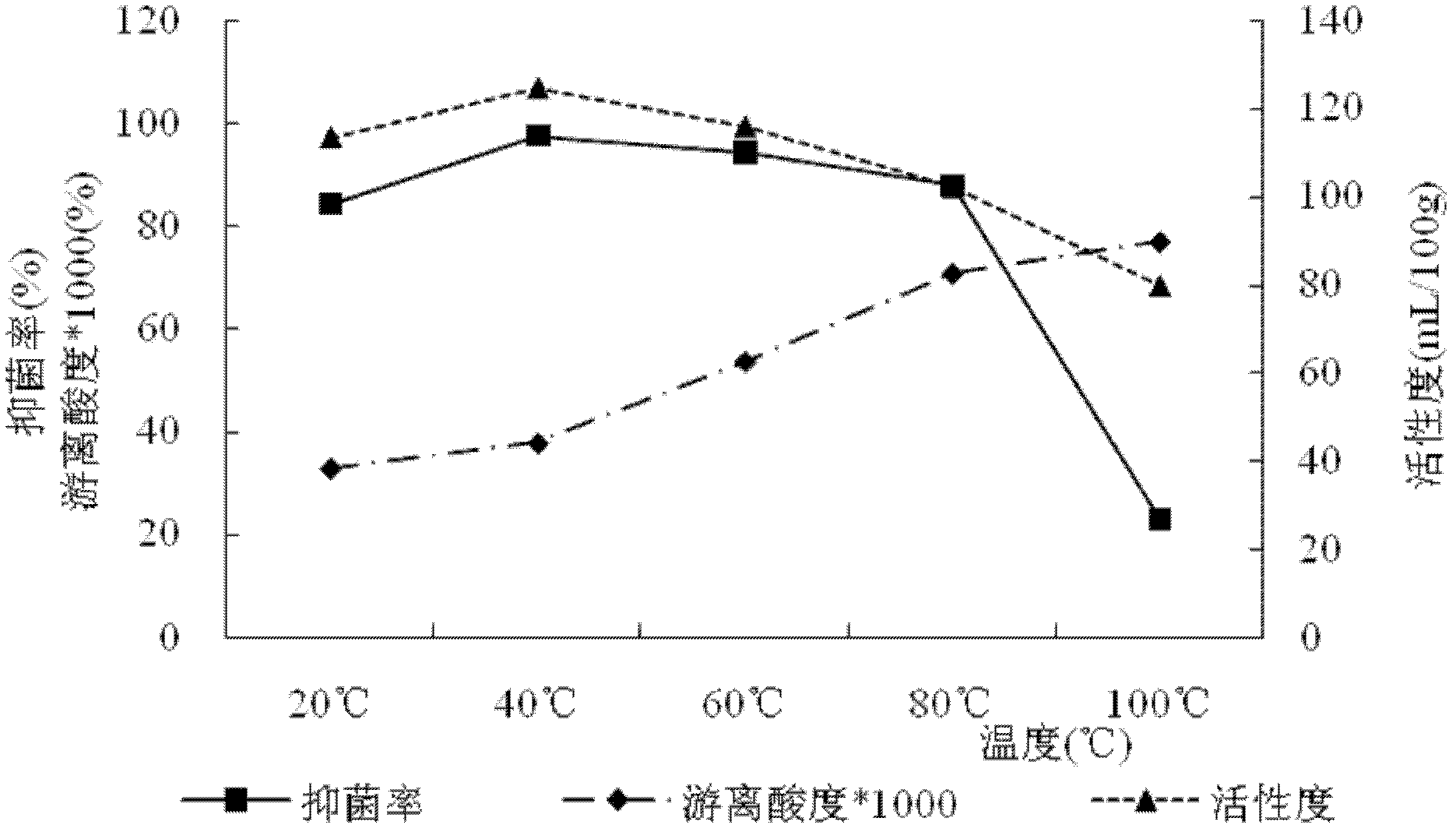

[0033] The effects of lactic acid concentration, water bath time and water bath temperature on the bacteriostatic rate of zeolite, free acidity and activity of zeolite were investigated respectively, and their influence on the bacteriostatic effect of lactic acid modified zeolite was studied.

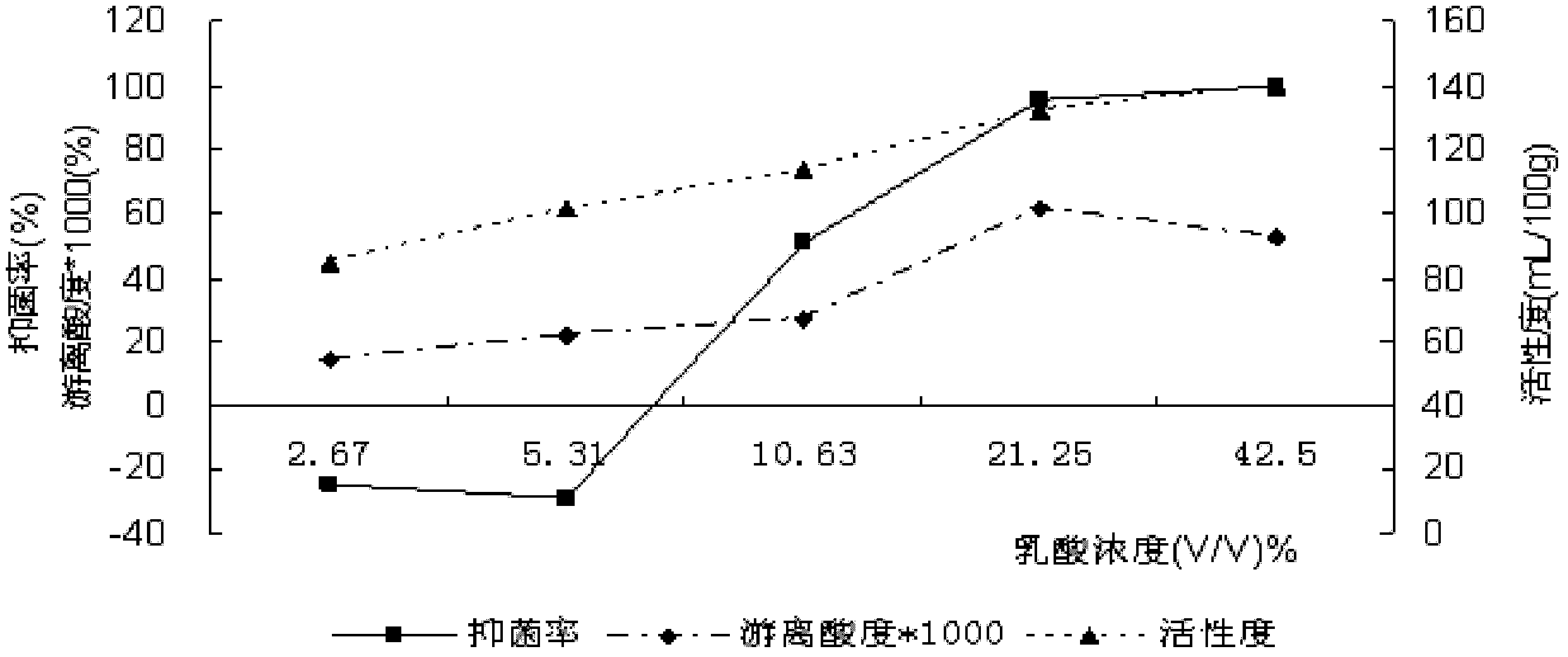

[0034] 1. The effect of lactic acid concentration on the antibacterial effect of zeolite

[0035] Lactic acid solutions with mass percent concentrations (W / W, g / g) of 2.67%, 5.31%, 10.63%, 21....

Embodiment 2

[0046] The preparation of embodiment 2 feed lactic acid modified zeolite (1)

[0047] The lactic acid modified zeolite for feed is produced according to the following preparation steps:

[0048] (1) To the natural zeolite, add a mass percent concentration (W / W, g / g) of 21.25% lactic acid solution (i.e. in 1 g of natural zeolite) according to the mass volume ratio (W / V, g / mL) 1:10 Add 10mL of lactic acid solution with a concentration of 21.25% by mass); the content of clinoptilolite in natural zeolite is not less than 60%, and the lactic acid used is feed or food or safe industrial lactic acid products.

[0049] (2) shake or stir the mixed solution prepared in step (1) at 20°C for 4 hours, filter and wash the filter residue until neutral;

[0050] (3) After drying the washed filter residue at 100° C., crush it to 200 mesh to obtain a lactic acid-modified zeolite product. The preparation of embodiment 3 feeding lactic acid modified zeolite (2)

Embodiment 3

[0050] (3) After drying the washed filter residue at 100° C., crush it to 200 mesh to obtain a lactic acid-modified zeolite product. The preparation of embodiment 3 feeding lactic acid modified zeolite (2)

[0051] The lactic acid modified zeolite for feed is produced according to the following preparation steps:

[0052] (1) In the natural zeolite, according to the mass volume ratio (W / V, g / mL) 1: 8, add the lactic acid solution that the mass percent concentration (W / W, g / g) is 40% (that is, in 1g natural zeolite Add 8 mL of lactic acid solution with a concentration of 40% by mass); the content of clinoptilolite in natural zeolite is not less than 60%, and the lactic acid used is feed or food or safe industrial lactic acid products.

[0053] (2) After shaking or stirring the mixed solution prepared in step (1) at 40°C for 4 hours, filter and wash the filter residue until neutral;

[0054] (3) After drying the washed filter residue at 80° C., crush it to 120 mesh to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com