Calcium dobesilate capsule composition

A technology of calcium dobesilate and composition, which is applied in capsule delivery, drug combination, anhydride/acid/halide active ingredients, etc. It can solve problems such as poor stability, light instability, easy oxidation, etc., and improve fluidity , stable sample quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention is further described below by way of examples.

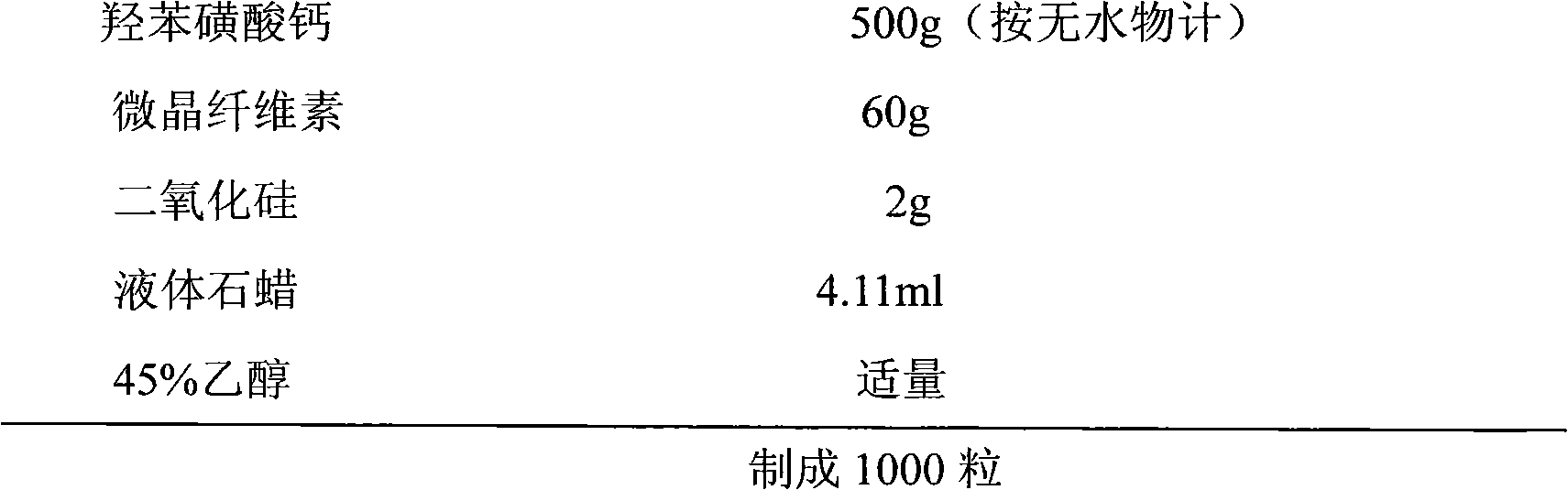

[0032] Embodiment one

[0033] prescription:

[0034]

[0035] Process:

[0036] 1. The calcium dobesilate is crushed through an 80-mesh sieve, and the microcrystalline cellulose is passed through an 80-mesh sieve;

[0037] 2. Weigh the prescription amount of calcium dobesilate and microcrystalline cellulose, and mix them;

[0038] 3. Use 45% ethanol as a wetting agent to make soft materials, pass through a 28-mesh sieve to granulate, dry the wet granules at 80°C, and take out the dry granules;

[0039] 4. Add the prescribed amount of liquid paraffin and silicon dioxide, mix evenly, pass through a 28-mesh sieve for granulation, and pack into No. 0 capsules.

Embodiment 2

[0041]

[0042] Process:

[0043] 1. The calcium dobesilate is crushed through an 80-mesh sieve, and the microcrystalline cellulose is passed through an 80-mesh sieve;

[0044] 2. Weigh the prescription amount of calcium dobesilate and microcrystalline cellulose, and mix them;

[0045] 3. Use 45% ethanol as a wetting agent to make soft materials, pass through a 28-mesh sieve to granulate, dry the wet granules at 80°C, and take out the dry granules;

[0046] 4. Add the prescribed amount of liquid paraffin and silicon dioxide, mix evenly, pass through a 28-mesh sieve for granulation, and pack into No. 0 capsules.

Embodiment 3

[0048]

[0049] Preparation Process:

[0050]1) The calcium dobesilate is pulverized through an 80-mesh sieve, and the filler is passed through an 80-mesh sieve;

[0051] 2) Weigh the prescription amount of calcium dobesilate, microcrystalline cellulose and lactose, and mix them;

[0052] 3) Use 45% ethanol as a wetting agent to prepare soft materials, pass through a 28-mesh sieve to granulate, dry the wet granules at 80°C, and take out the dry granules;

[0053] 4) Add the prescribed amount of silicon dioxide and liquid paraffin, mix evenly, pass through a 28-mesh sieve for granulation, and pack into No. 0 capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com