Multiple circulating column outside micro-bubble mineralizing flotation column

A technology of multiple cycles and flotation columns, applied in flotation, solid separation, etc., can solve problems such as difficult metal ore beneficiation process, difficult to control the aluminum-silicon ratio of tailings, and unclear description of technical solutions, so as to improve mineral Recovery rate, increase recovery rate, reduce investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

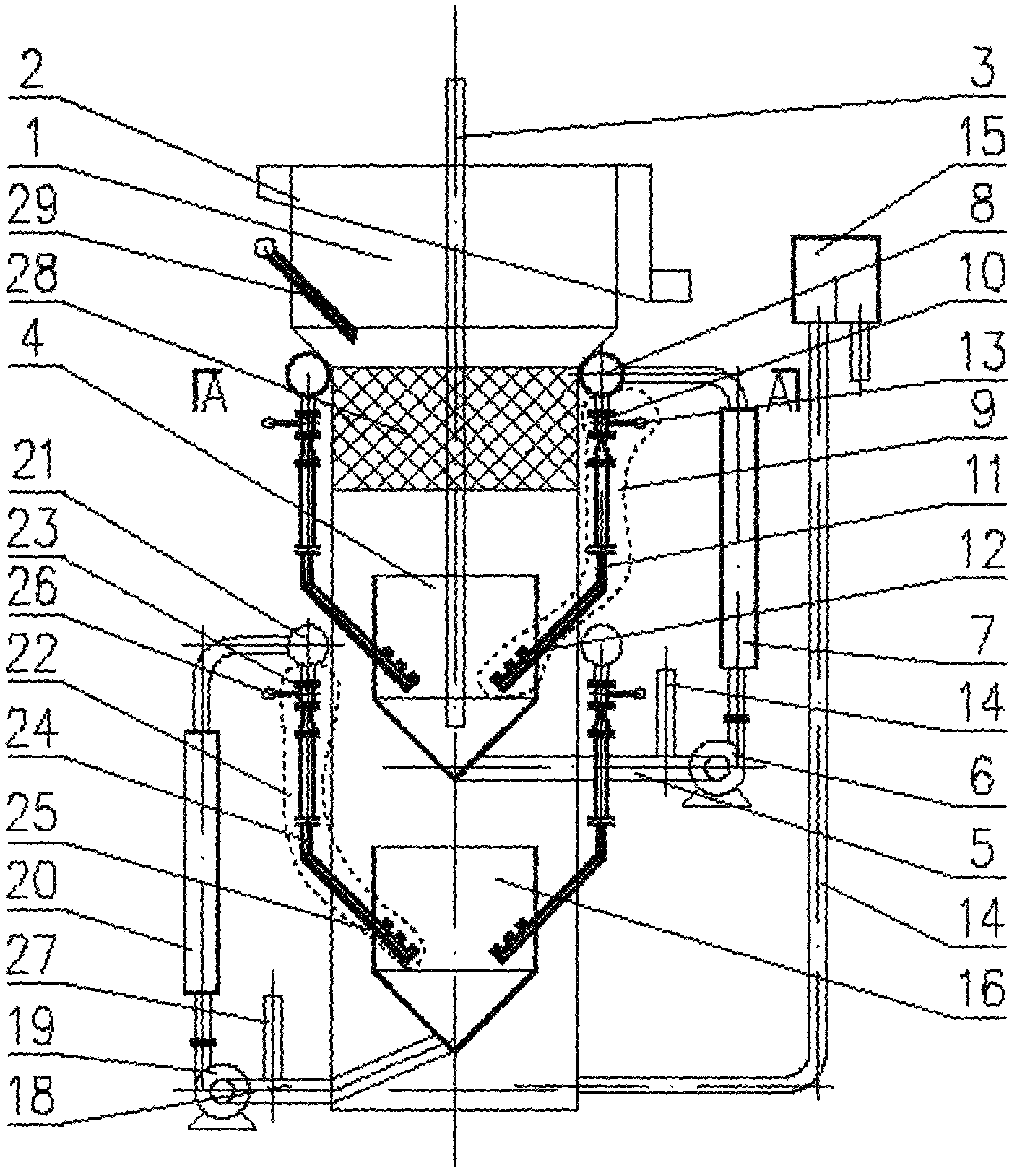

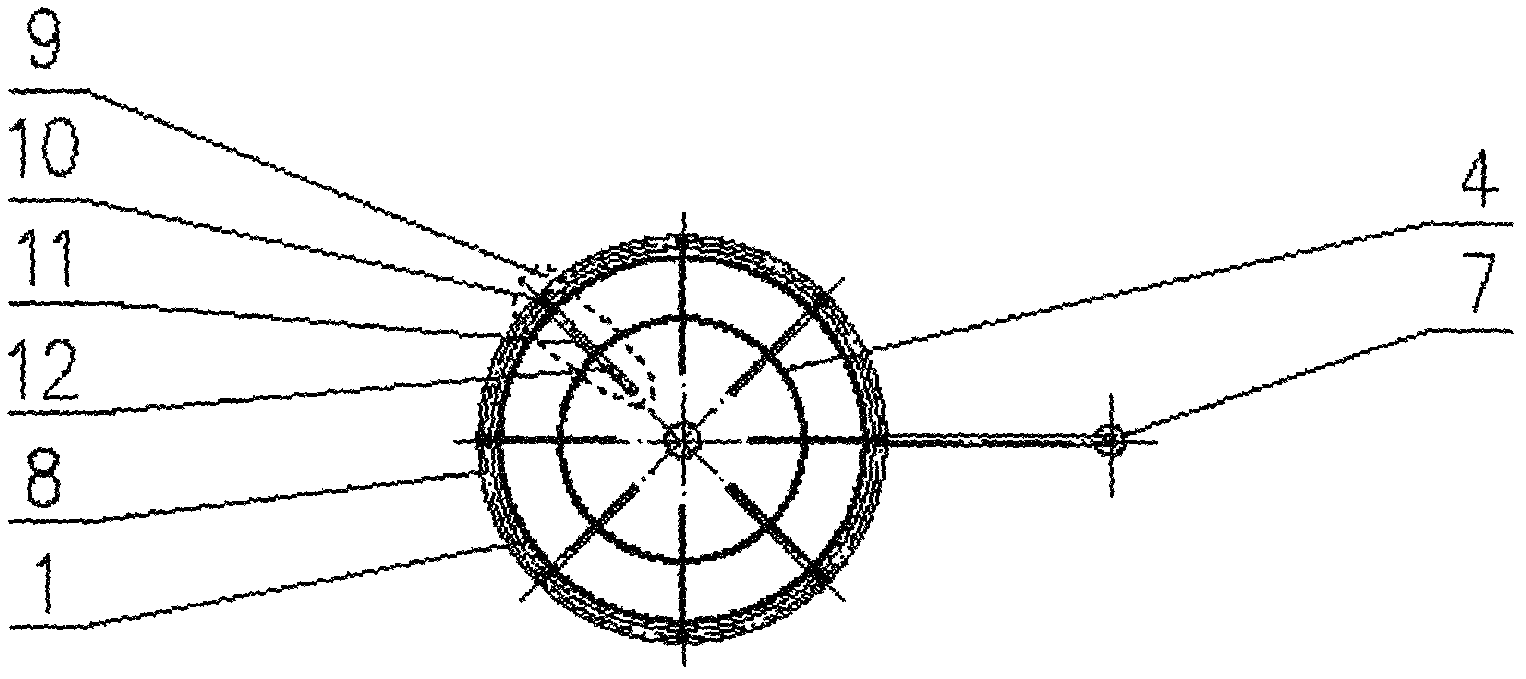

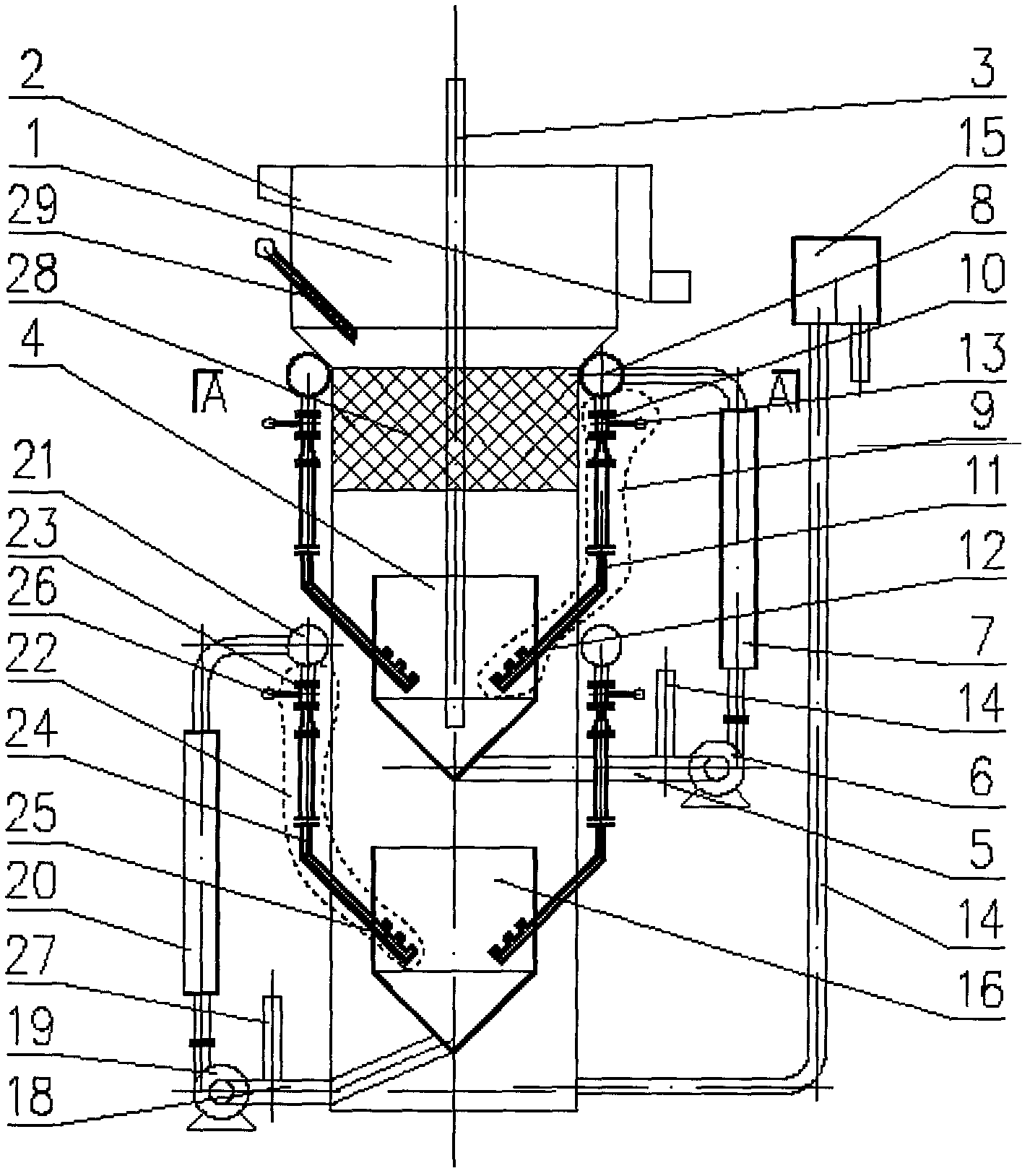

[0019] Designed to pass 50m 3 / h bauxite slurry multiple circulation column external micro-bubble mineralization flotation column, column (1) design size is 2600mm in diameter, 10m in height, foam discharge chute (2) width 300mm, upper circulation tapered trough ( 4) The diameter is 1800mm, the depth is 1000mm, the taper is 45°, the upper circulation pump feed pipe (5), the upper circulation pump (6), the upper circulation mineralization feed ring pipe (8), and 6 upper circulation mineralizers Group (9), 6 upper circulation mineralization inflatable tubes (13) as attached figure 1 Connection, the upper circulation mineralizer (10), the upper circulation mineralization pipe (11), and the upper circulation mineralization release head (12) in the upper circulation mineralizer group (9) are sequentially connected in series, and each upper circulation mineralizer The upper circulation mineralizer (10) on the group (9) is all charged with compressed air through the upper circulatio...

specific Embodiment 2

[0020] Designed to pass 100m 3 / h bauxite slurry multiple circulation column external micro-bubble mineralization flotation column, column body (1) design size is 3600mm in diameter, height is 12m, foam discharge chute (2) width 400mm, upper circulation tapered trough ( 4) The diameter is 2800mm, the depth is 1000mm, the taper is 45°, the upper circulation pump feed pipe (5), the upper circulation pump (6), the upper circulation mineralization feed ring pipe (8), and 10 upper circulation mineralizers Group (9), 10 upper circulation mineralization inflation tubes (13) as attached figure 1 Connection, the upper circulation mineralizer (10), the upper circulation mineralization pipe (11), and the upper circulation mineralization release head (12) in the upper circulation mineralizer group (9) are sequentially connected in series, and each upper circulation mineralizer The upper circulation mineralizer (10) on the group (9) is all filled with compressed air through the upper circ...

specific Embodiment 3

[0021] Designed to pass 100m 3 / h raw coal slurry multi-circulation micro-bubble mineralization flotation column outside the column, the column (1) is designed with a diameter of 3600mm, a height of 12m, a foam discharge chute (2) with a width of 400mm, and an upper circulation tapered trough (4) The diameter is 2800mm, the depth is 1000mm, the taper is 45°, the upper circulation pump feed pipe (5), the upper circulation pump (6), the upper circulation mineralization feed ring pipe (8), and 10 upper circulation mineralizer groups ( 9), 10 upper circulation mineralization inflation pipes (13) as attached figure 1 Connection, the upper circulation mineralizer (10), the upper circulation mineralization pipe (11), and the upper circulation mineralization release head (12) in the upper circulation mineralizer group (9) are sequentially connected in series, and each upper circulation mineralizer The upper circulation mineralizer (10) on the group (9) is all filled with compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com