Moving mechanism of brush of dry brushing machine

A technology of motion mechanism and dry brushing machine, which is applied in the direction of metal processing equipment, metal rolling, manufacturing tools, etc. It can solve problems such as difficult removal of scale and impurities, unsatisfactory effect, and inconvenient brush maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

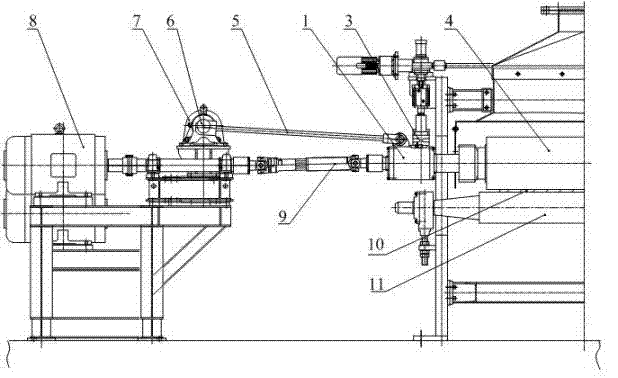

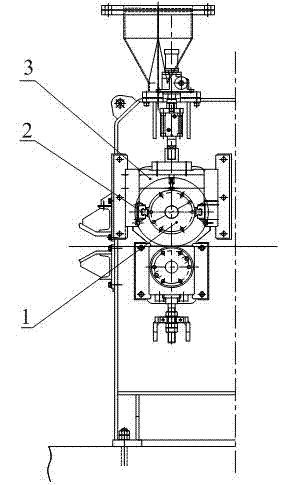

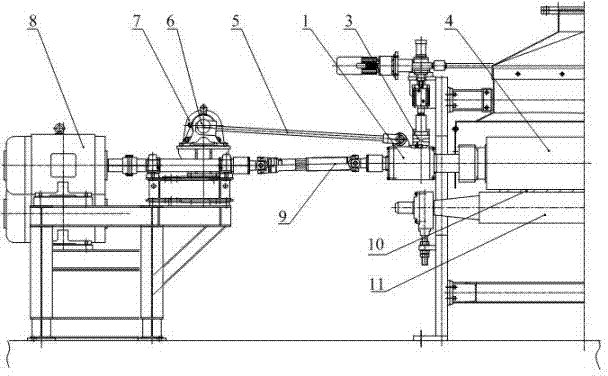

[0015] Such as figure 1 , figure 2 As shown, the movement mechanism of the brush of the dry brushing machine includes a fixed bearing seat 3, a movable bearing seat 1, a guide rail 2, a brush rotation motor 8 and a brush linear movement motor 7, the brush 4 is located above the back roller 11, and the guide rail 2 includes rails and installation The slider in the track, the slider is fixed on the fixed bearing seat 3, the track is fixed on the mobile bearing seat 1, the rotating shaft of the brush 4 is supported on the mobile bearing seat 1, and the rotating shaft of the brush 4 passes through the telescopic coupling 9 is connected with the output shaft transmission of the brush rotating motor 8, and the mobile bearing seat 1 is connected with the eccentric wheel 6 through the connecting rod 5, and the eccentric wheel 6 is installed on the output shaft of the brush linear moving motor 7.

[0016] The fixed bearing seat 3 cannot move in the axial direction of the brush, but c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com