Extrusion die for preparation of flat pipes of micro-channel heat exchangers

A micro-channel heat exchanger and extrusion die technology, applied in metal extrusion die and other directions, can solve the problems of increasing die weight, insufficient pressure bearing capacity, and shortening die life, saving die manufacturing costs, reducing production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention are described in detail below. Based on the premise of the technical solution of the present invention, the present embodiment provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

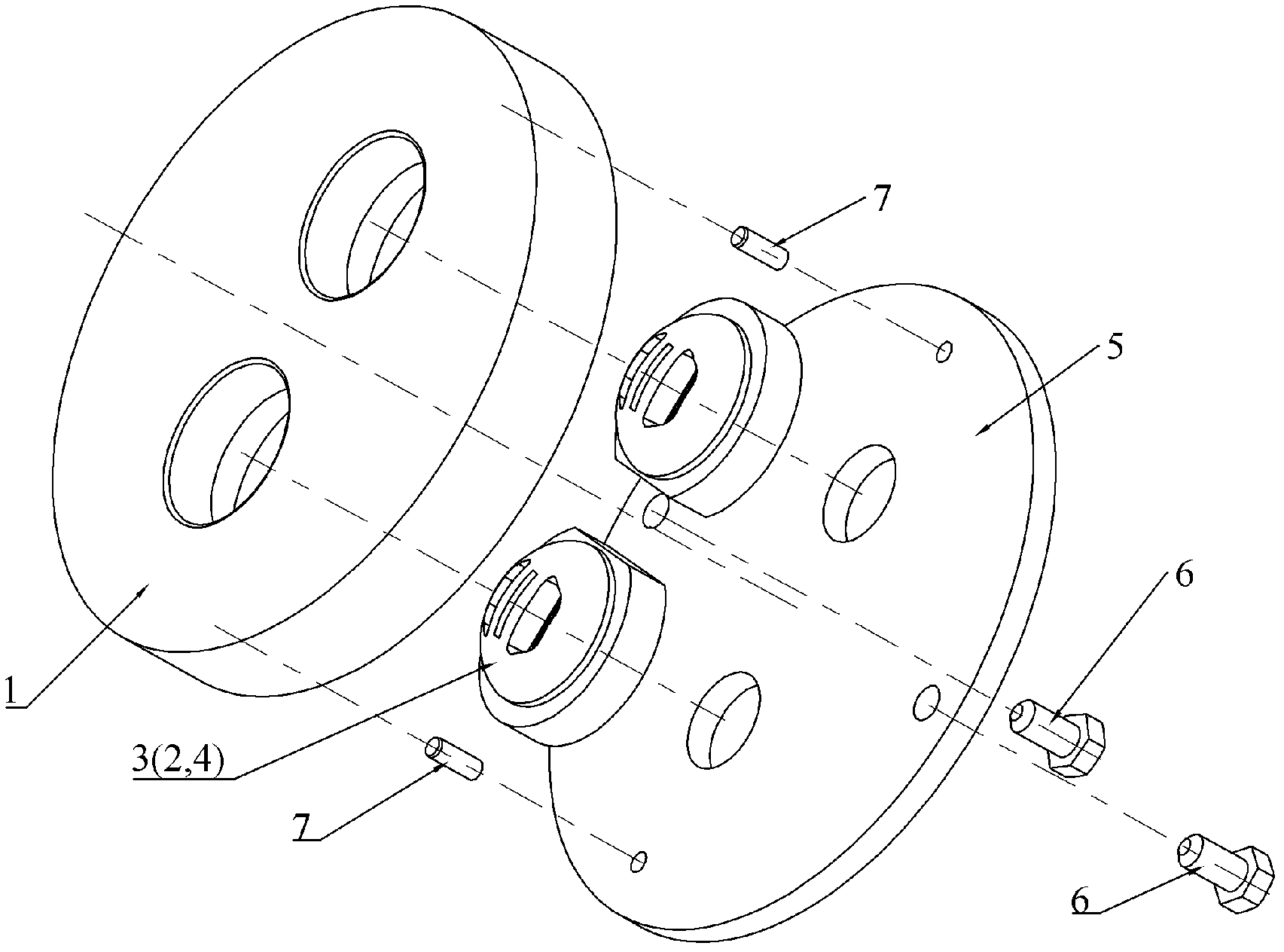

[0044] see figure 1 , is an explosion schematic diagram of an extrusion die of an embodiment of the present invention, wherein the extrusion die of the flat tube of the microchannel heat exchanger includes two sets of splitter dies 3, mandrel 2 and cavity die 4, which can realize "one out two "Squeeze way. When assembling the mold, first assemble two sets of splitter molds 3, mandrel 2 and cavity mold 4; then insert the previously assembled parts into the main mold cover 1, and use two pins 7 and two screws 6 to secure the main mold cover Connect with the liner mold sleeve 5.

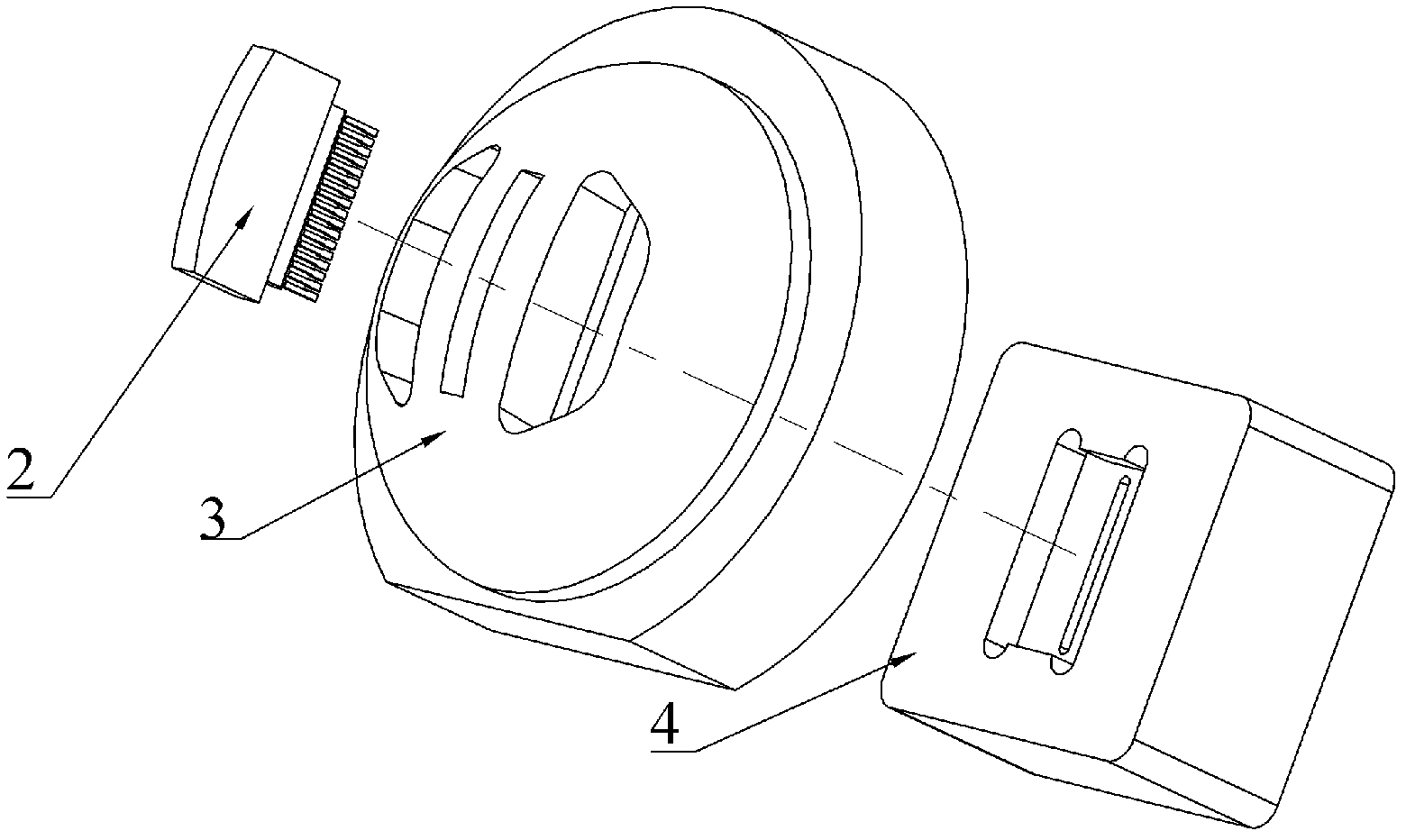

[0045] see figure 2 , is an exploded schematic view of the assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com