Visual real-time deviation rectifying system and visual real-time deviation rectifying method for robot

A robot vision and robot technology, applied in auxiliary devices, arc welding equipment, auxiliary welding equipment, etc., can solve the problems of real-time and unreliable control accuracy of the robot deviation correction system, saving conversion time, reducing control complexity, reducing The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

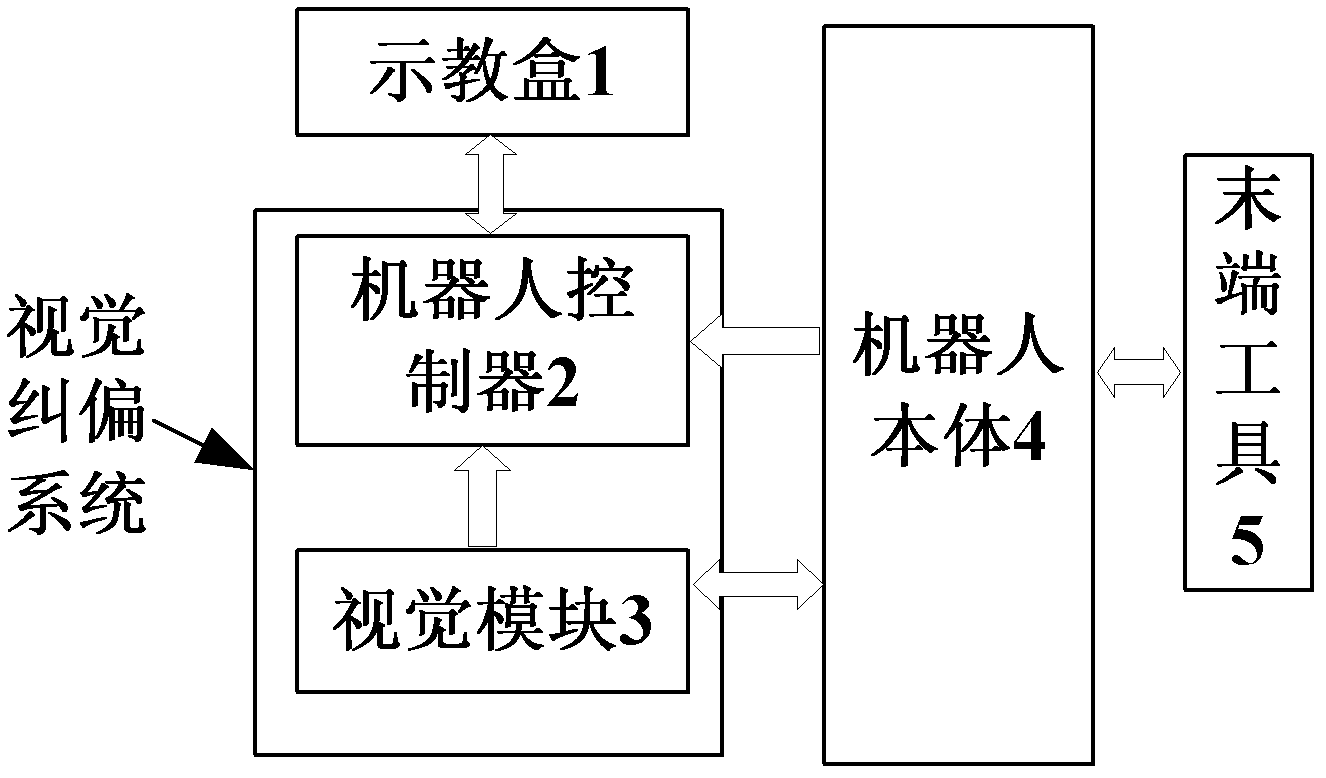

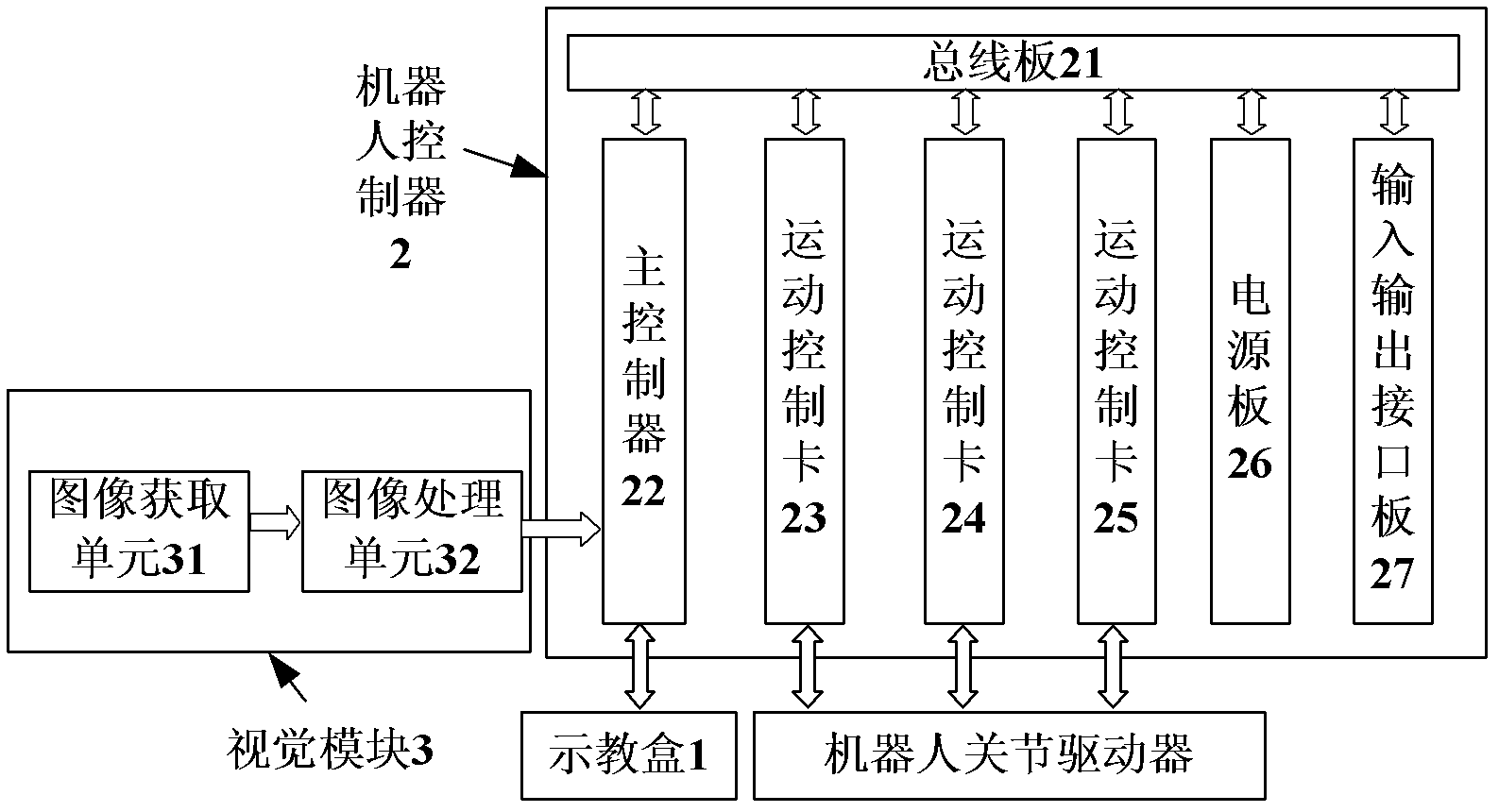

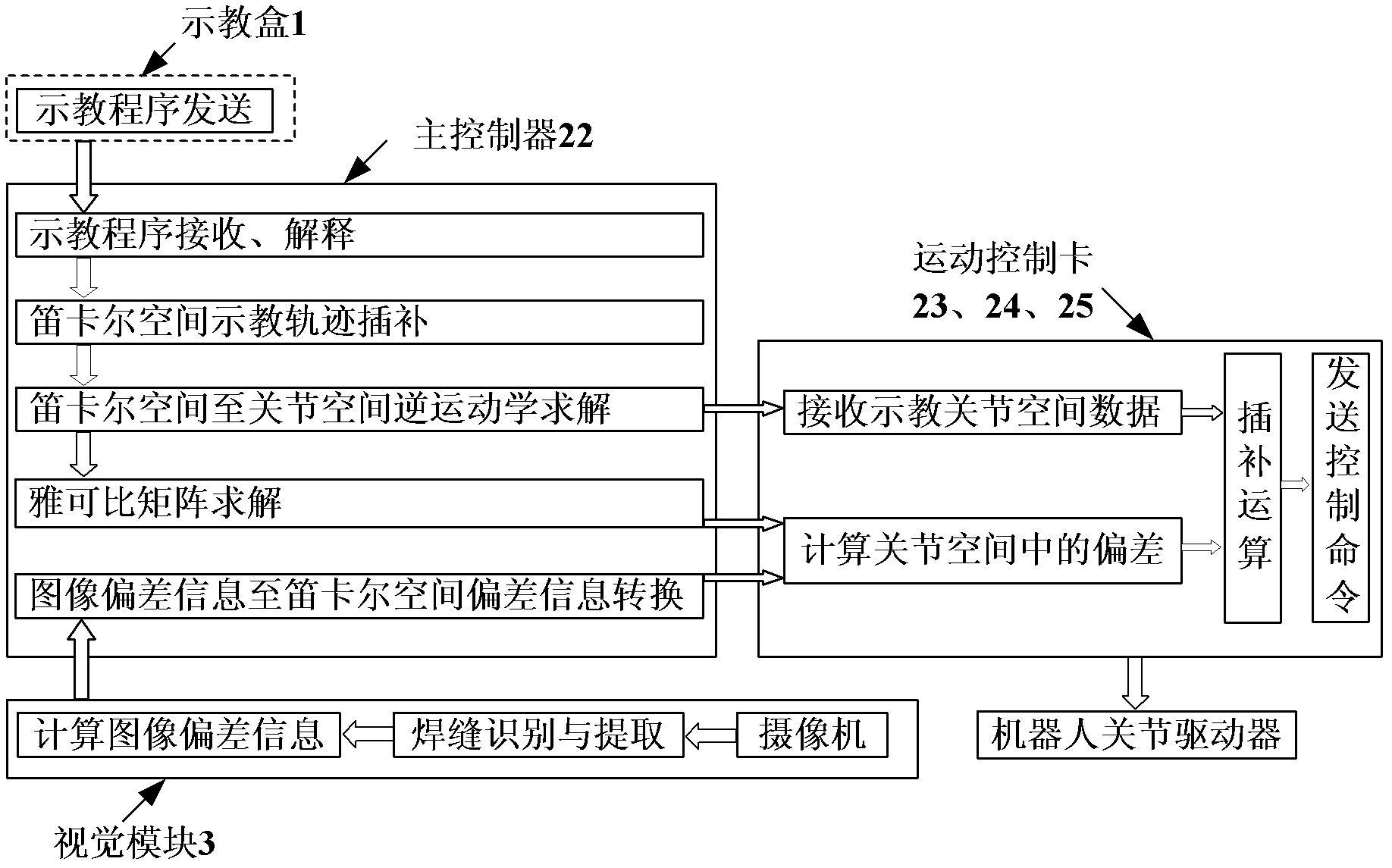

[0025] According to the present invention, a robot vision real-time deviation correction system is composed of a vision module and a robot controller. The robot includes a robot body and an end tool installed at the end of the body. The vision module is installed at the front end of the end tool and rigidly connected with the end tool to ensure a fixed positional relationship between the vision module and the end tool. The robot controller consists of a main controller, a motion control card, a power supply board and an input and output interface board. The main controller mainly completes the generation of Cartesian space trajectory, the conversion of joint space trajectory, the conversion of position deviation informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com