Device for correcting butt joint 'II-shaped' misalignment of flat-bulb steel

A technology of spherical flat steel and main board, which is applied in the field of auxiliary devices for "Type II" dislocation correction of spherical flat steel, which can solve problems such as adding welding code boards, removing code boards, reducing enterprise competitiveness, and affecting production efficiency. Improve assembly quality, fast loading and unloading, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

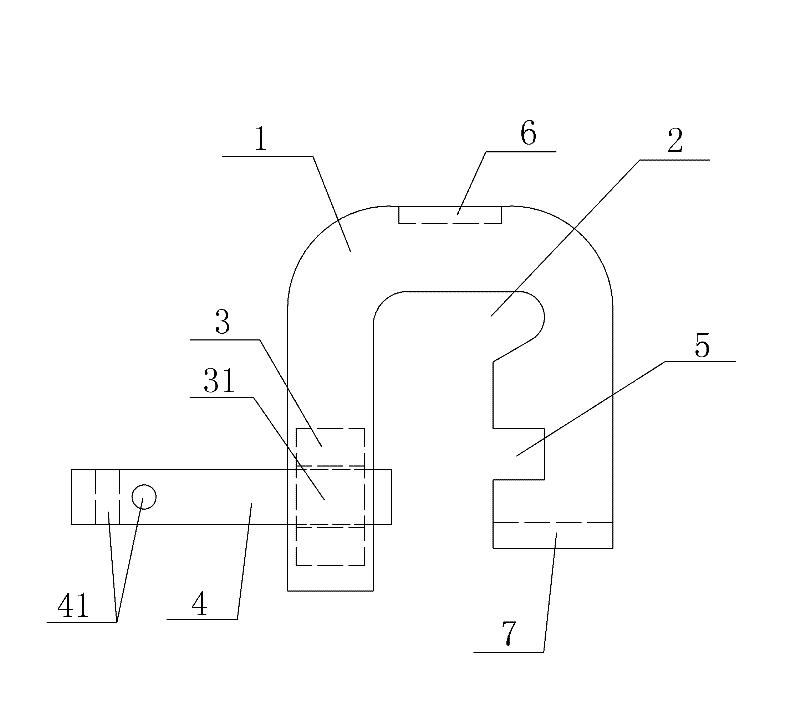

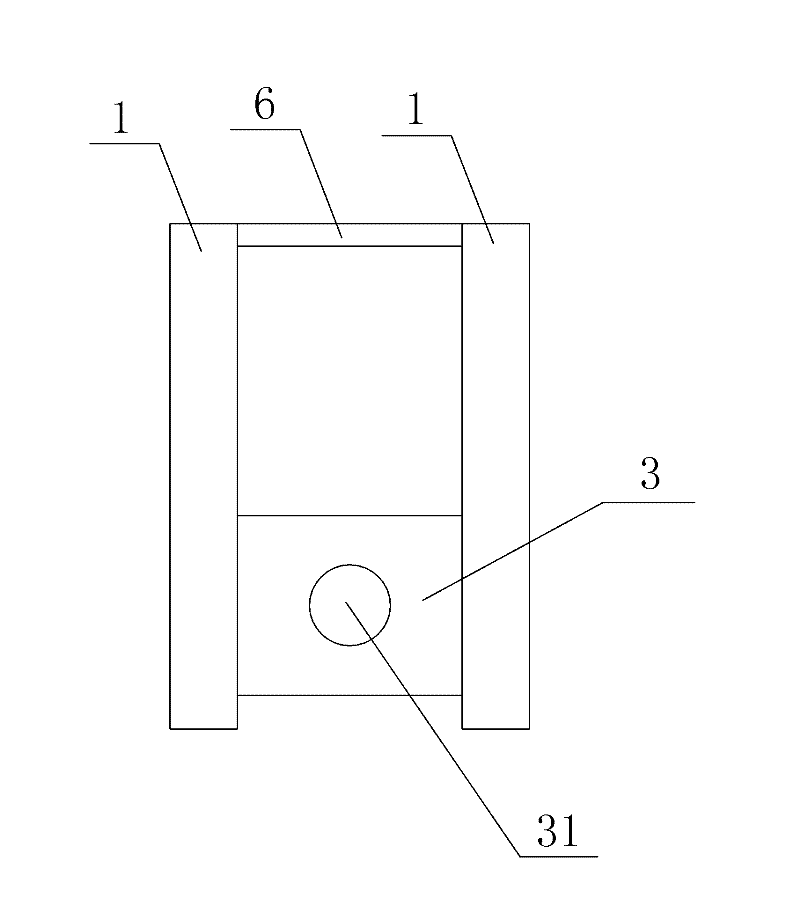

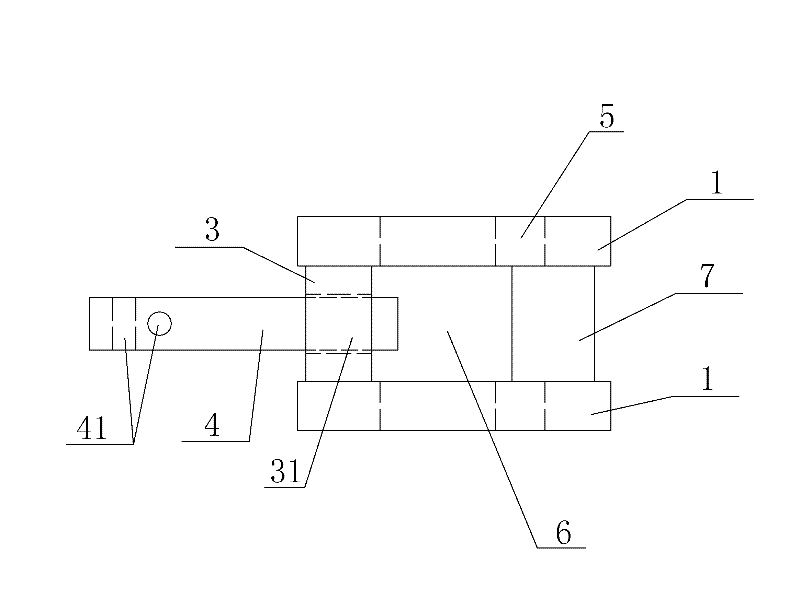

[0019] refer to figure 1 - Figure 5 , a device for correcting "Type II" misalignment of the flat bulb steel 8 according to the present invention, comprising two main boards 1, the main board 1 is provided with a model hole 2 corresponding to the cross-sectional shape of the flat bulb steel 8, the main board 1 and the main board 1 are connected together through a nut plate 3, the nut plate 3 is provided with a nut hole 31, and a screw 4 is threaded on the nut hole 31, and the top of the screw 4 is facing the middle or the height of the bulb flat steel 8 At the position near the middle and high part, there is an iron point jack 5 on the main board 1 on the side opposite to the nut plate 3 .

[0020] The main board 1 is provided with a model hole 2 matching the cross-sectional shape of the spherical flat steel 8, which can facilitate the installation of the correcting device on the dislocated spherical flat steel 8 according to the model hole 2, wherein the two main boards 1 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com