Online automatic detecting device for abrasion state of rotating body tool

An automatic detection device, tool wear technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as inability to increase standby time, reduce production efficiency, etc., to reduce production costs and save natural resources , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail as follows:

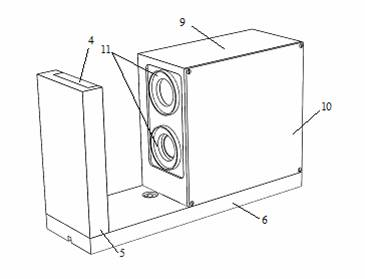

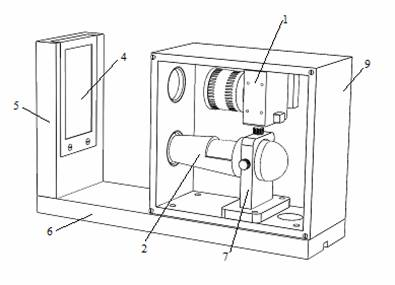

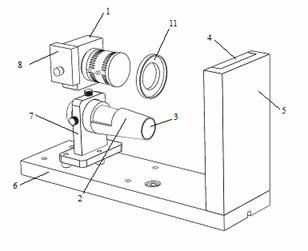

[0030] see Figure 1 ~ Figure 4 , an online automatic detection device for the wear state of a rotary tool, comprising a device base 6, a tool optical detection system, a centralized control system and a tool wear alarm system, the device base 6 is fixedly installed on the workbench of a machine tool for a rotary tool, The tool optical detection system is fixedly installed on the device base 6 through the device bracket. The tool optical detection system is an area array image sensor system. The image data signal output end of the tool optical detection system is connected to the signal receiving end of the centralized control system. The centralized control system The alarm command signal output end of the tool is connected to the signal receiving end of the tool wear alarm system. The tool optical detection system includes a tool overall measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com